Ultralow temperature vacuum insulation quick connector and production method thereof

A technology of vacuum insulation and connectors, which is applied in the direction of heat preservation, couplings, heat exchange equipment, etc. It can solve the problems of slow installation of connection methods, inability to open quickly, and unsafety, so as to prevent malfunctions and fast and safe connections and the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

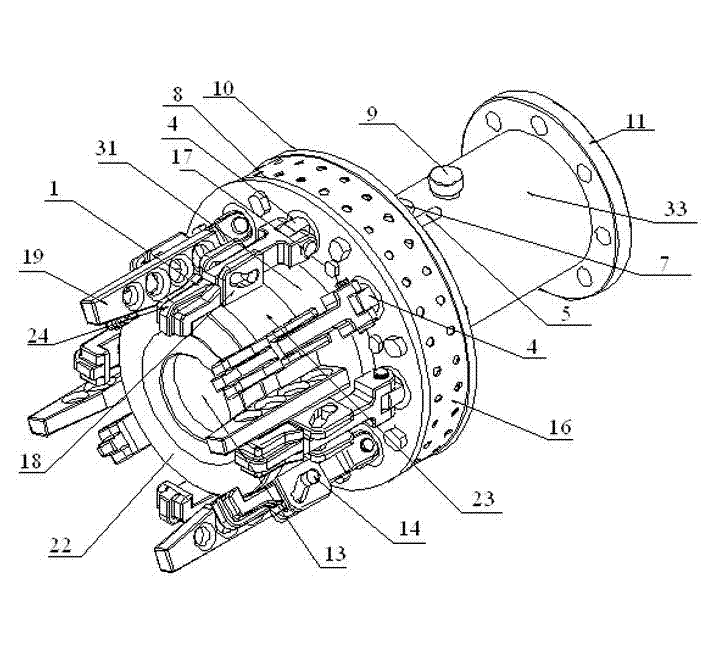

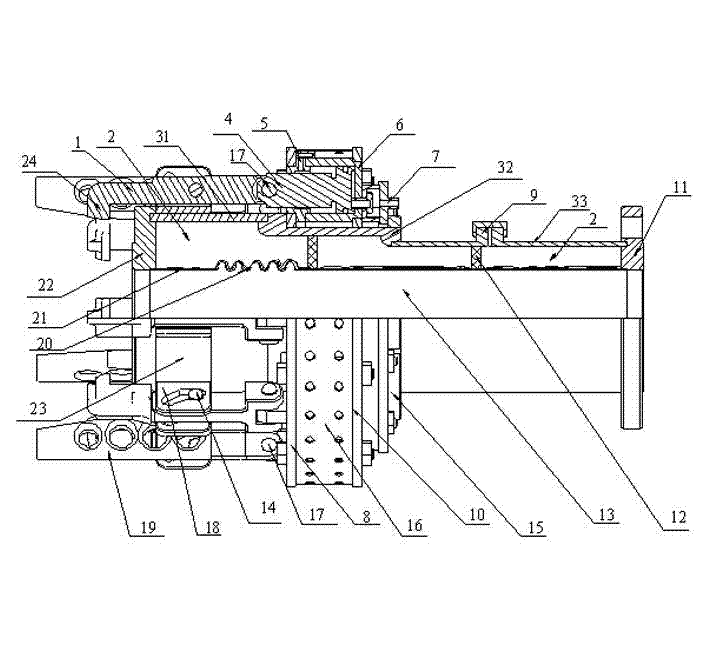

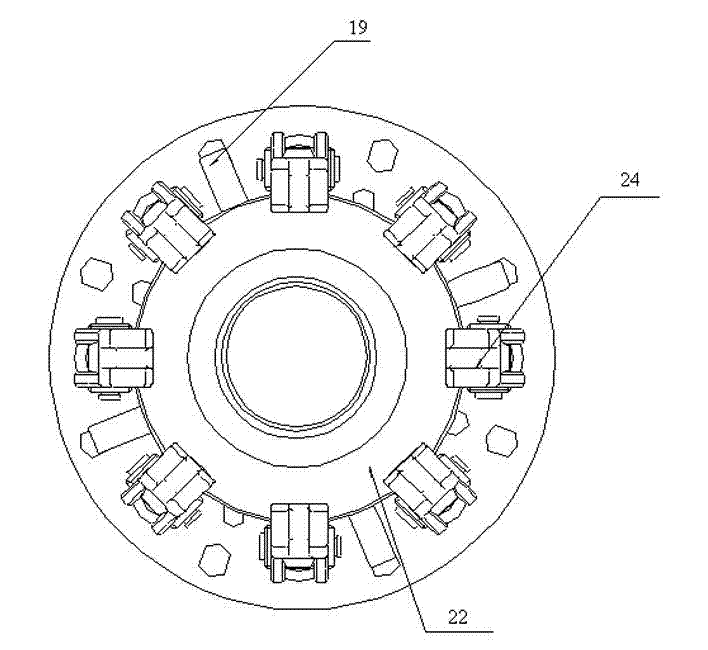

[0019] Such as Figure 1 to Figure 3 As shown, the ultra-low temperature vacuum insulation quick connector of the present invention includes a pull rod 1, a vacuum chamber 2, a first outer tube 31, a second outer tube 32, a third outer tube 33, a piston rod 4, a first oil port 5, an oil cylinder 6, The second oil port 7, the first oil cylinder splint 8, the vacuum port 9, the second oil cylinder splint 10, the connecting flange 11, the supporting ring 12, the flow channel 13, the guide shaft 14, the fixing ring 15, the protective cover 16, the connecting shaft 17 , guide plate 18, guide rod 19, corrugated inner tube 20, multi-layer insulation layer 21, butt joint flange 22, ring-type rotary body 23, claw 24, pull rod 1 and claw 24 are integrally formed, and pull rod 1 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com