Anti-falling-off nut

A nut, screw technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of loosening, the fixed object cannot be completely fixed, and the heat dissipation efficiency is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

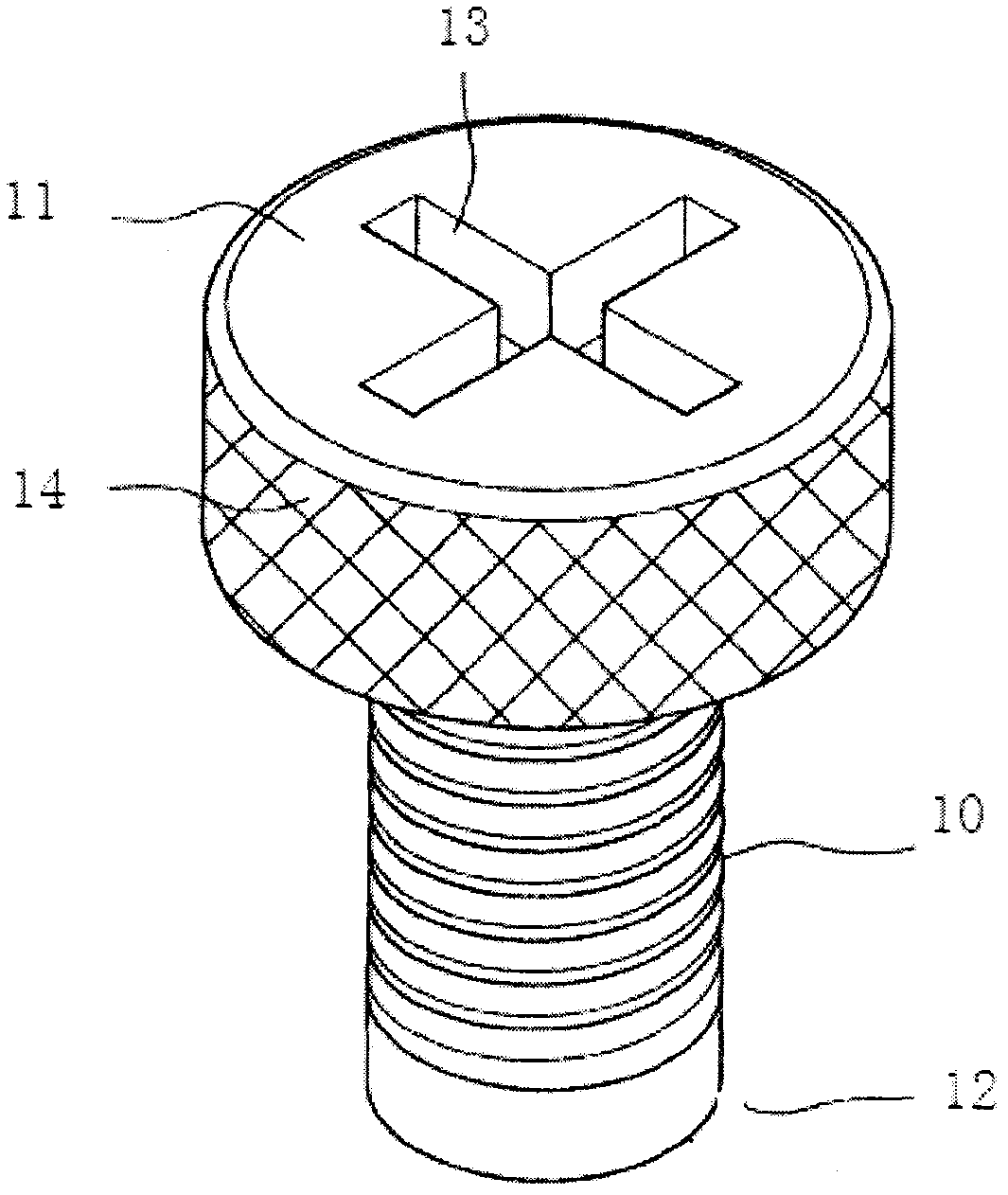

[0009] The present invention will be further described below in conjunction with accompanying drawing.

[0010] Such as figure 1 As shown, an anti-falling nut includes a screw main body 1, a screw plate surface 10, an internal thread hole 11, a threaded wall surface 12, a threaded surface 13 and a ring groove 14, and one side of the screw main body 1 extends outward to form the internal thread of the screw plate surface 10 The outer edge of the hole 11 is extended with a threaded wall surface 12 with a high convex screw plate surface 10, the inner edge surface of the threaded wall surface 12 is provided with a threaded surface 13 extending continuously with the internal thread hole 11, and the outer edge surface is between the screw plate surface 10 A ring groove 14 is formed. The screw main body 1 is made of plastic.

[0011] One side of the nut body is integrally extended with a disk surface, and a threaded wall surface higher than the disk surface is extended outward from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com