Hydraulic system for hydraulic pile hammer

A technology of hydraulic piling hammer and hydraulic system, applied in the field of hydraulic system of hydraulic piling hammer, can solve rare problems and other problems, and achieve the effect of obvious effect, shortening pipeline length and simplifying hydraulic system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

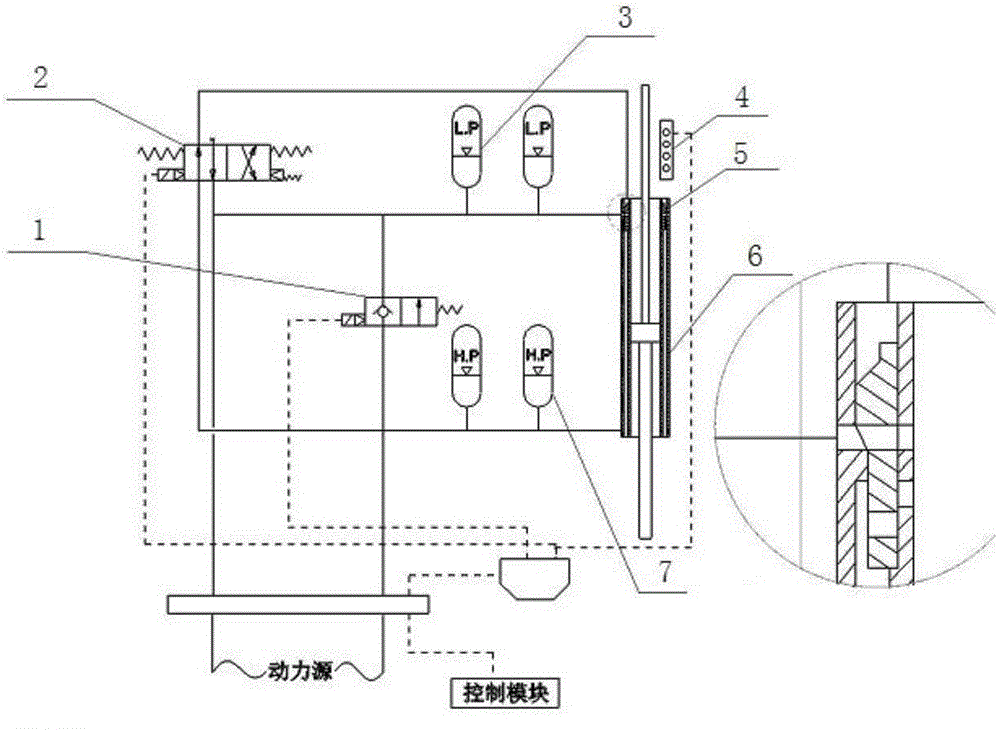

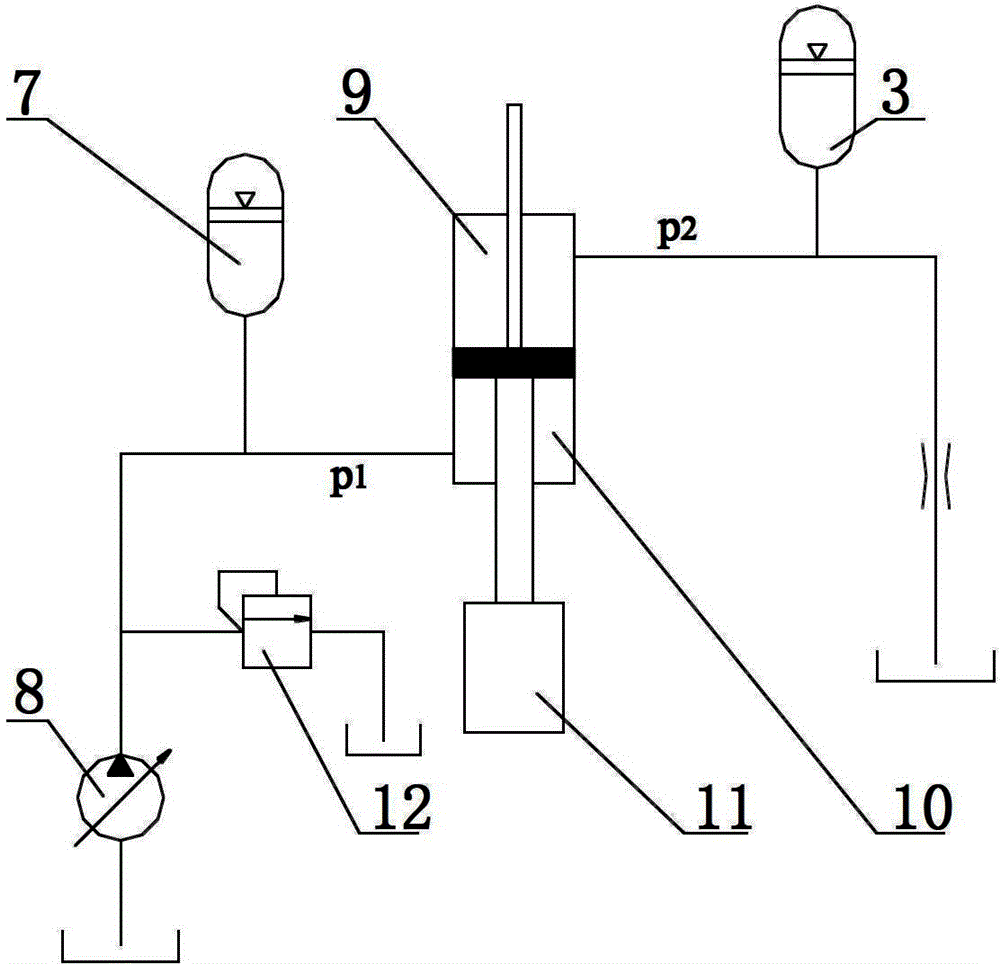

[0027] A hydraulic system of a hydraulic piling hammer, the system includes a double-wall hydraulic cylinder 6, a hydraulic slide valve 5, a load valve 1, a two-position four-way control valve 2, a low-pressure accumulator group 3, a hydraulic hammer travel switch group 4, a high-pressure The accumulator group 7 and the power source; the high-pressure accumulator group 7 is located at the oil inlet of the lower chamber of the double-wall hydraulic cylinder 6, and the low-pressure accumulator group 3 is located at the oil discharge port of the upper chamber of the double-wall hydraulic cylinder 6. A hydraulic spool valve 5 is arranged between the inner wall of the cylinder 6 and the outer wall of the double-wall hydraulic cylinder 6; the oil outlet T port of the load valve 1 is connected to the oil discharge port of the upper chamber of the double-wall hydraulic cylinder 6, and the connection position of the T port is in the low-pressure accumulator Before the position of the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com