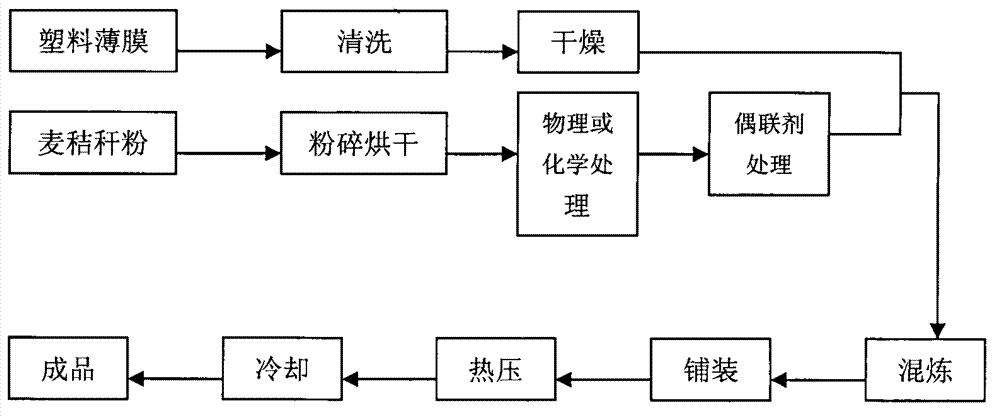

Process for preparing wheat straw/plastic film composite material

A composite material and a preparation process technology, applied in the field of composite materials, can solve the problems of low utilization rate, low binding force, inability to solve the problem of wheat straw being difficult to bond, etc., and achieves improved anti-hygroscopic and water-absorbing performance, excellent friction and wear performance, and is economically practical. Advantageous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] In Example 1, the wheat straw powder was soaked in NaOH solution with a mass fraction of 5% for 48 hours, and then rinsed until the pH test paper was neutral, and dried; KH550 silane coupling agent and ethanol were mixed according to a volume ratio of 1:5 Solution, put the wheat straw powder pretreated in the first step into a high-speed mixing mixer, spray the coupling agent solution while stirring, until the coupling agent solution fully soaks the wheat straw powder uniformly, take it out, and dry at 105°C. The wheat straw and polypropylene film after the composite treatment are mixed in a mixer to promote the uniform dispersion of the fiber in the matrix. The temperature of the roller before mixing is 175℃, and the temperature of the rear roller is 165℃, and the time is 5-7 minutes. It is molded into a plate vulcanizer, the hot pressing temperature is 180°C, the pressure is 12.5MPa, and the time is 12min.

Embodiment 2

[0013] In Example 2, the wheat straw powder was soaked in 5% acetic acid solution for 48 hours, and then rinsed until the pH test paper was neutral, and dried; KH550 silane coupling agent and ethanol were mixed according to the volume ratio of 1:5 Solution, put the wheat straw powder pretreated in the first step into a high-speed mixing mixer, spray the coupling agent solution while stirring, until the coupling agent solution fully soaks the wheat straw powder uniformly, take it out, and dry at 105°C. The wheat straw and polypropylene film after the composite treatment are mixed in a mixer to promote the uniform dispersion of the fiber in the matrix. The temperature of the roller before mixing is 175℃, and the temperature of the rear roller is 165℃, and the time is 5-7 minutes. It is molded into a plate vulcanizer, the hot pressing temperature is 180°C, the pressure is 12.5MPa, and the time is 12min.

Embodiment 3

[0014] Example 3, place wheat straw powder in a constant temperature pot with deionized water for steaming, temperature 90℃, time 2h, take out to dry, and dry at 105℃; mix KH550 silane coupling agent and ethanol according to the volume ratio of 1:5 Into a solution, put the wheat straw powder pretreated in the first step into a high-speed mixing mixer, spray the coupling agent solution while stirring, until the coupling agent solution fully and evenly infiltrate the wheat straw powder, take it out, and dry at 105°C. The wheat straw and polypropylene film after the composite treatment are mixed in a mixer to promote the uniform dispersion of the fiber in the matrix. The temperature of the roller before mixing is 175℃, and the temperature of the rear roller is 165℃, and the time is 5-7 minutes. It is molded into a plate vulcanizer, the hot pressing temperature is 180°C, the pressure is 12.5MPa, and the time is 12min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com