Method for preparing isotactic polyacrylonitrile and application thereof

An isotactic, polyacrylonitrile technology, which is applied in the field of preparing isotactic polyacrylonitrile, can solve the problems of low isotacticity of polyacrylonitrile triads, and achieves improved stereoregularity, Keep the arrangement neat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mix 2.2 grams of 280um urea (produced by Sinopharm Group) and 0.8 ml of acrylonitrile (produced by Sinopharm Group) into the reaction bottle (ratio of substances: acrylonitrile: urea = 1:3), and freeze at -60 degrees Celsius for 150 hour, add liquid nitrogen in the reaction bottle afterwards, carry out gamma ray irradiation, the irradiation dose is 28.8kGy, after the irradiation, the reaction bottle is moved into the environment of -60 degrees Celsius, and the nitrogen gas of -60 degrees Celsius is passed into the reaction bottle, The flow rate was 400 L / h, and after the polymerization was carried out for 4 hours, it was repeatedly washed with water, filtered, and dried.

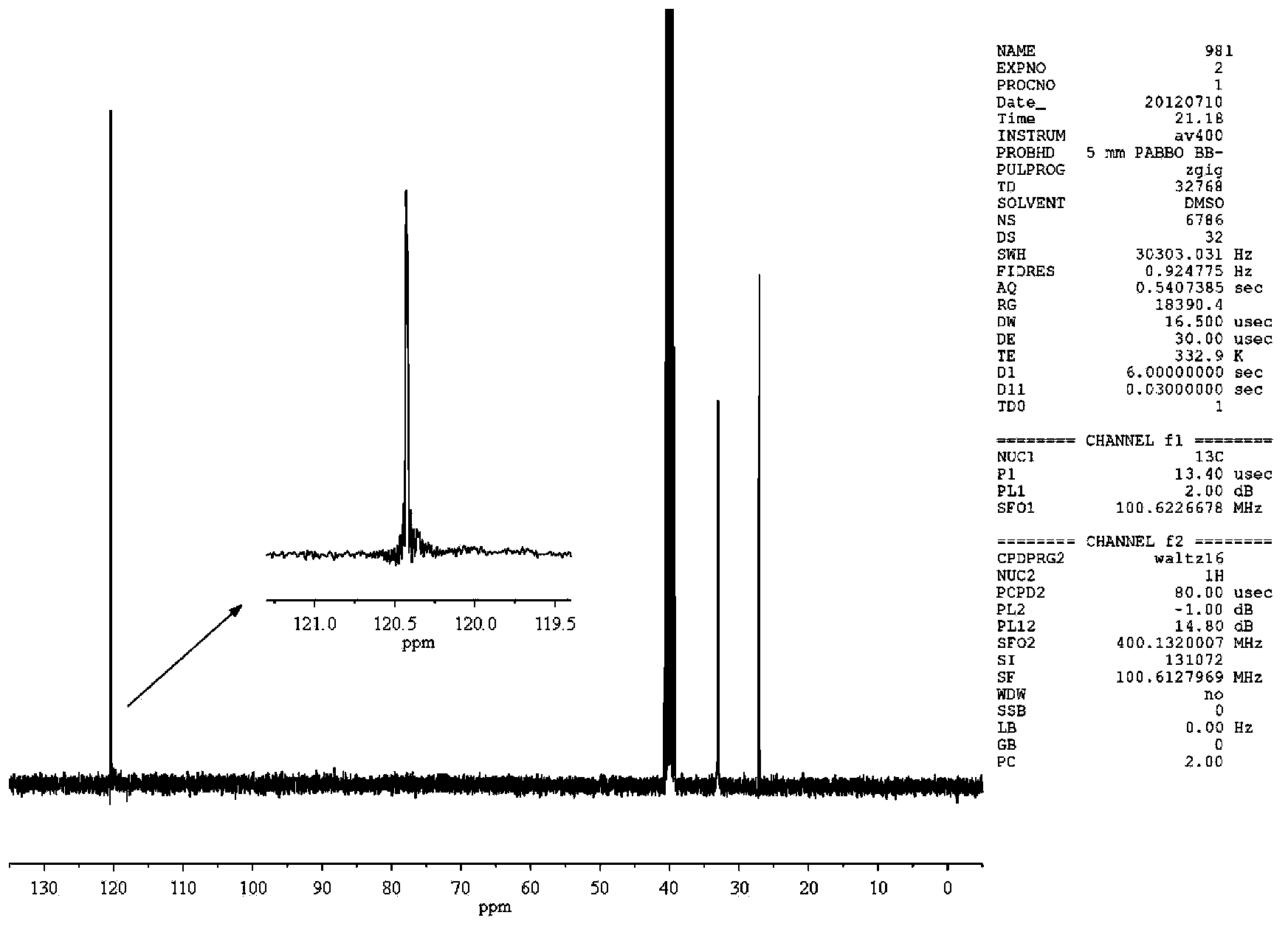

[0035] The polymerization yield is 48%, and the number-average molecular weight of the obtained isotactic polyacrylonitrile is 30580, and the molecular weight distribution is 1.28, and the three-unit isotacticity is 98% (see figure 1 ).

[0036] The abscissa in the figure is the chemical shift (ppm),...

Embodiment 2

[0038] Mix 2.2 grams of 150um urea (produced by Sinopharm Group) and 0.8 ml of acrylonitrile (produced by Sinopharm Group) into the reaction bottle (ratio of substances: acrylonitrile: urea = 1:3), and freeze at -45 degrees Celsius for 100 After that, liquid nitrogen was added to the reaction bottle, and Co60γ-ray irradiation was carried out. The irradiation dose was 72kGy. After the irradiation, the reaction bottle was moved into the environment of -110 degrees Celsius, and the nitrogen gas of -110 degrees Celsius was passed into the reaction bottle. After polymerization at 300 L / h for 8 hours, washing with water, filtration, and drying were repeated.

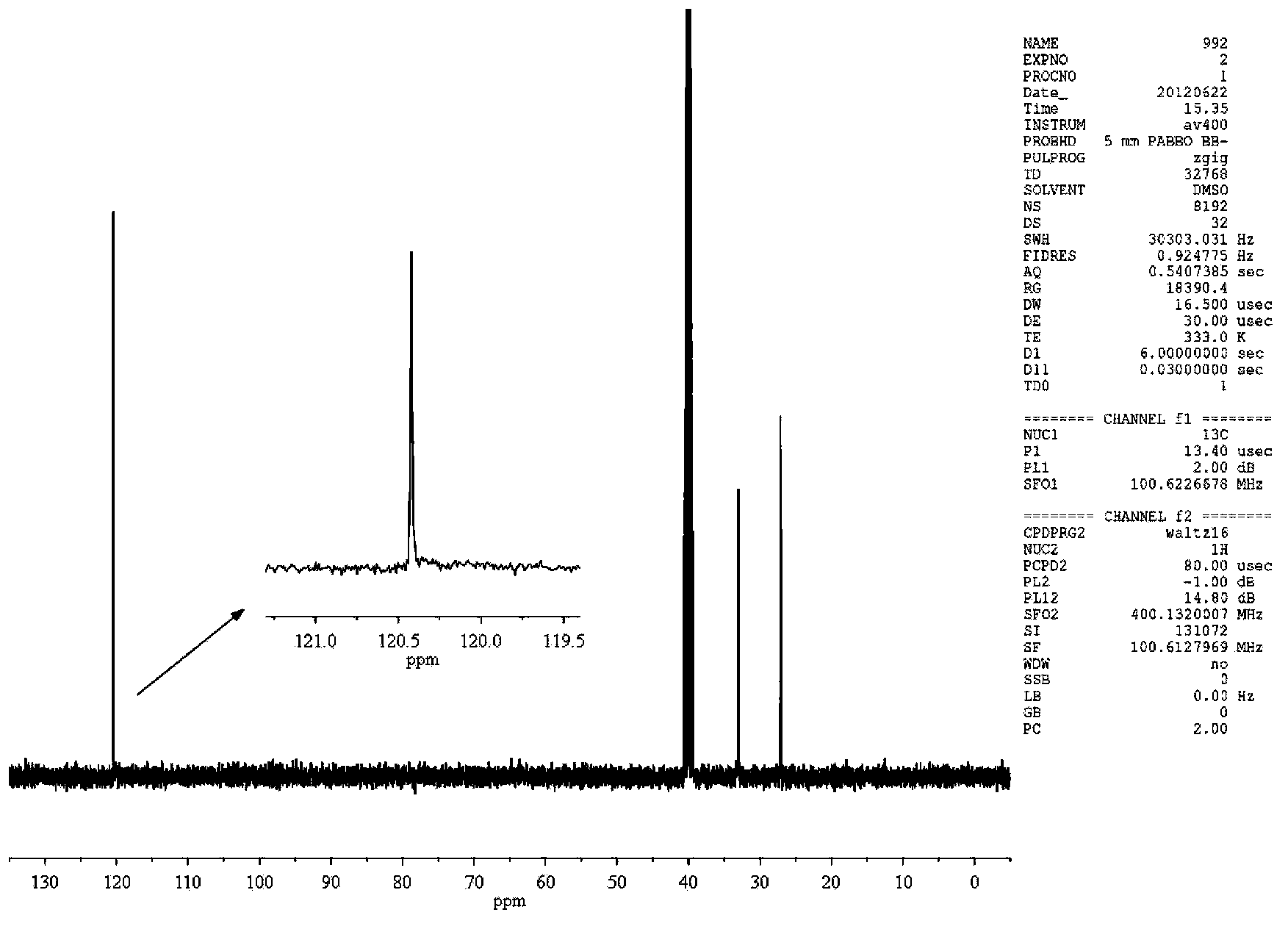

[0039] The polymerization yield is 68%, and the number-average molecular weight of the obtained isotactic polyacrylonitrile is 19470, and the molecular weight distribution is 1.41, and the three-unit isotacticity is 99% (see figure 2 ).

Embodiment 3

[0041] Mix 0.61 g of 150um urea (produced by Sinopharm Group) and 0.8 ml of acrylonitrile (produced by Sinopharm Group) into the reaction bottle (ratio of substances: acrylonitrile: urea = 1:0.83), freeze at -60 degrees Celsius for 400 hour, add liquid nitrogen in the reaction bottle afterwards, carry out Co60 gamma ray irradiation, irradiation dose is 66.6kGy, after irradiation, move the reaction bottle into the environment of -95 degrees centigrade, pass into the nitrogen of -95 degrees Celsius in the reaction bottle, The flow rate was 50 L / h, and after the polymerization was carried out for 5 hours, it was repeatedly washed with water, filtered, and dried.

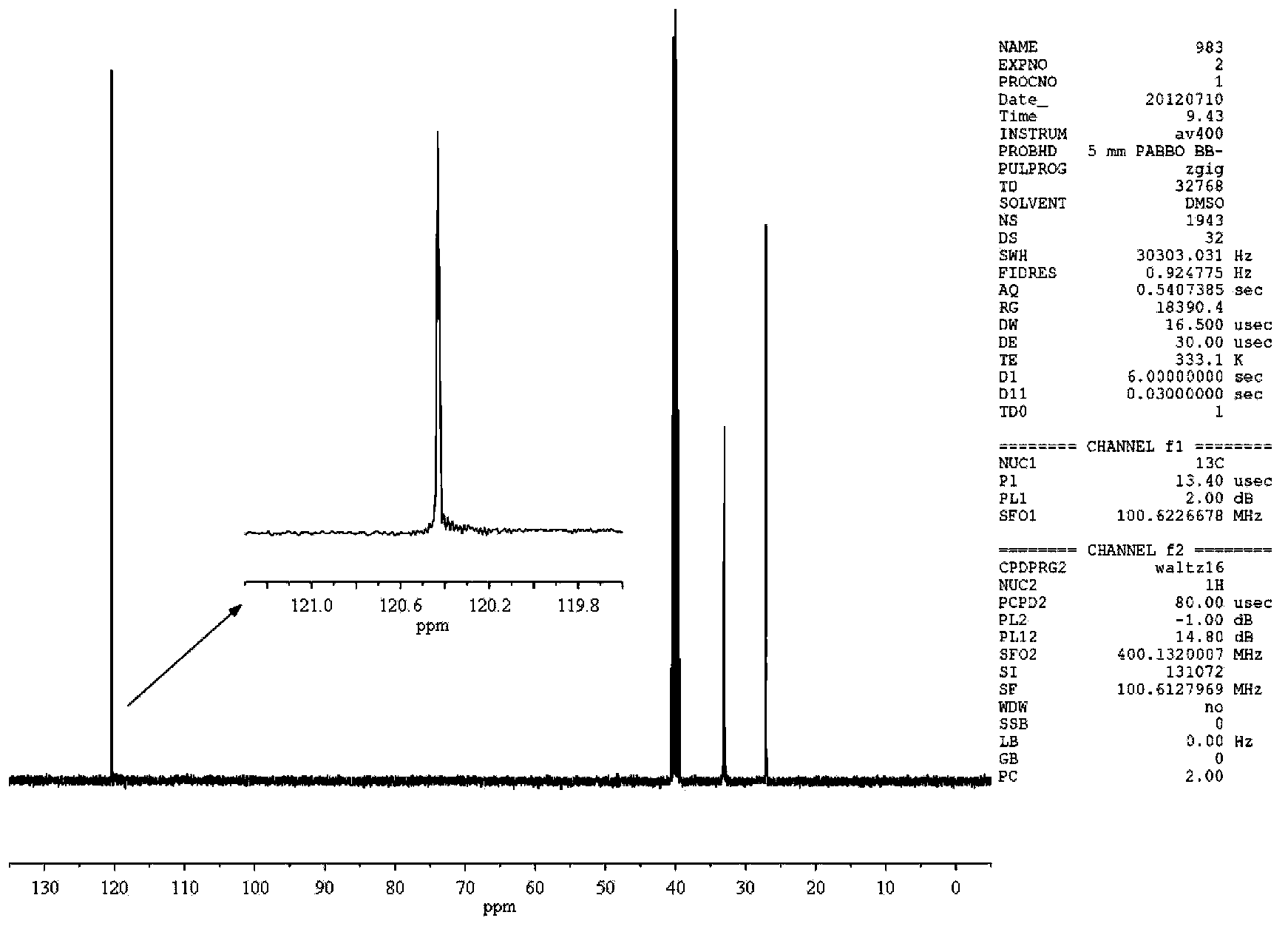

[0042] The polymerization yield is 62.5%, and the number-average molecular weight of the obtained isotactic polyacrylonitrile is 18280, and the molecular weight distribution is 1.31, and the three-unit isotacticity is 99% (see image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com