Hydraulic double-decker beam feeding car

A double-layer, hydraulic technology, applied in the direction of hoisting devices, lifting equipment safety devices, etc., can solve the problems of no safety device, the machine cannot operate normally, and takes up a lot of space, achieving good promotion value and simple and practical structure , the effect of shortening the downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

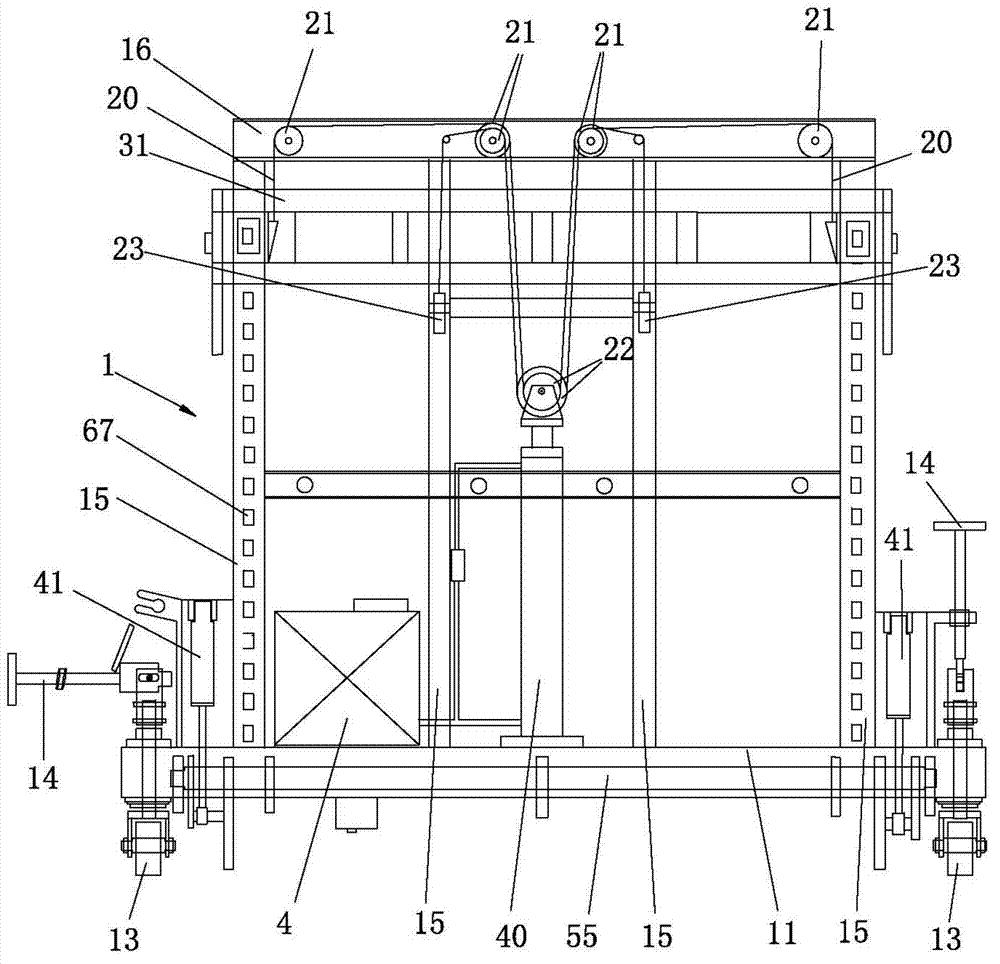

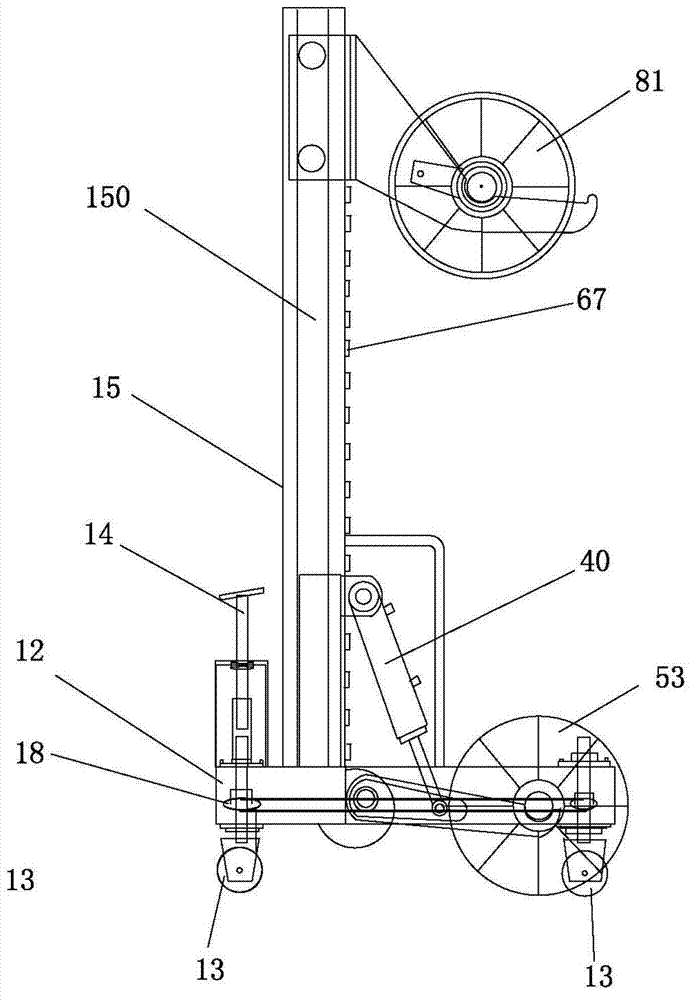

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

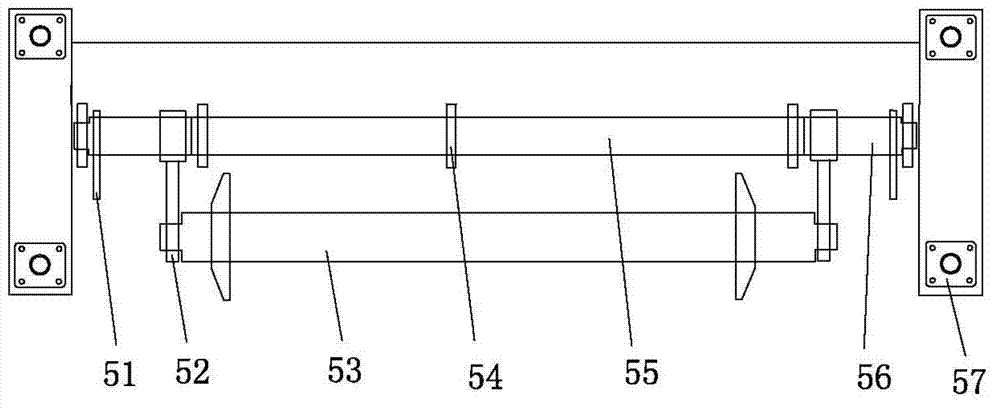

[0012] The hydraulic double-layer upper shaft car of the present invention mainly includes a body, a hydraulic system, an upper lifting mechanism, a lower lifting mechanism, a pulley mechanism, and a steering system. The upper lifting mechanism includes an upper lifting beam for supporting the upper warp beam, and the lower lifting mechanism includes The lower lifting beam for supporting the lower warp beam.

[0013] Such as figure 1 and 2 As shown, the chassis of the body 1 includes a beam 11 and two left and right side beams 12, each side beam 12 is equipped with two wheels 13 and a steering handle 14, the steering handle 14 is used to control the direction of the wheels 13. A sprocket transmission mechanism 18 is installed under the steering handle 14, which is linked to the front wheels, so as to realize the synchronization of the front and rear wheels, making th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com