Automatic stacking paper-laying machine and paper laying method thereof

A technology of automatic stacking and paper laying, which is applied to stacking receiving devices, winding strips, sending objects, etc., which can solve problems such as inability to achieve consistency and accuracy, affecting the overall appearance of products, and uneven products. , to achieve the effect of perfecting the paper laying process, reducing work-related accidents and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

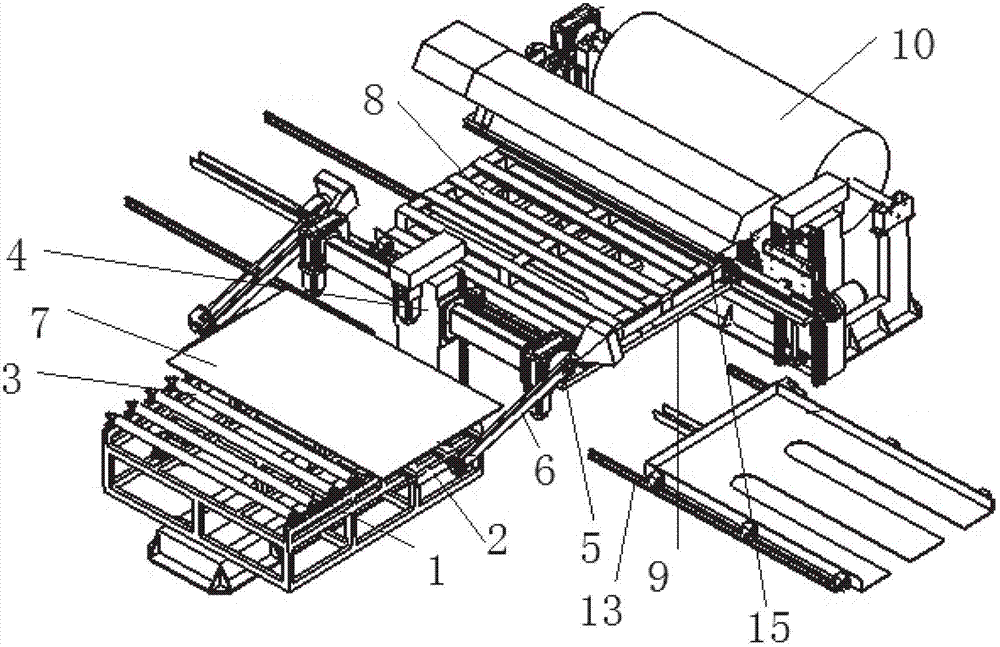

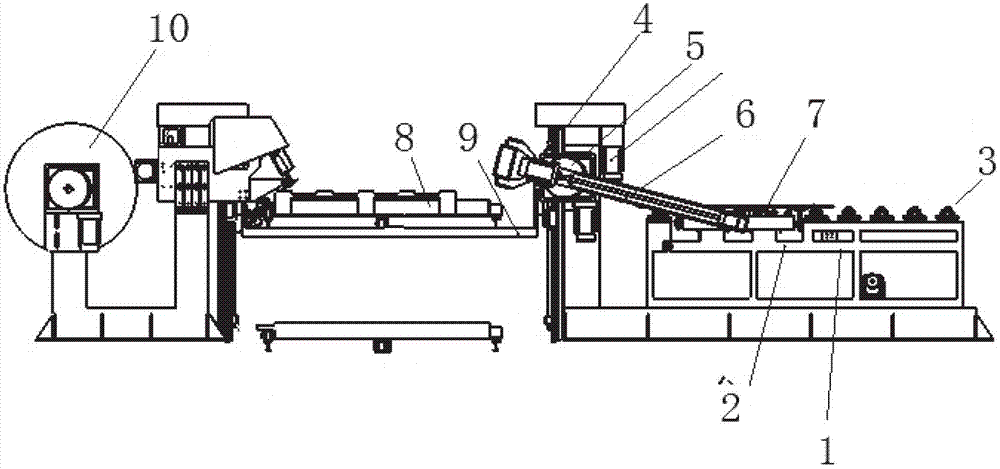

[0023] Such as Figure 1~Figure 3 An automatic stacking and laying machine is shown, including a glass transition mechanism, a glass turning mechanism, a tray lifting mechanism, a glass tray 8, a paper cutting mechanism, and a paper feeding mechanism. The glass transition mechanism is arranged on one side of the glass turning mechanism. The glass tray 8 is arranged on the other side of the glass turning mechanism.

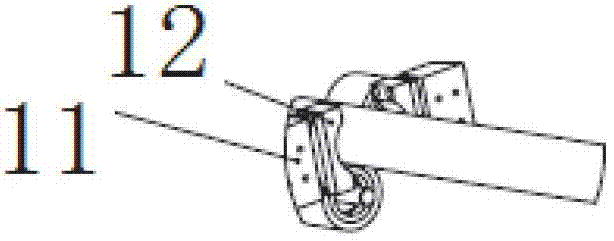

[0024] The glass transition mechanism includes a support frame 1 on which a glass temporary storage table 2 and a plurality of conveying rollers 3 are arranged. The glass turning mechanism includes a rotating shaft bracket 4, a turning shaft 5 connected to the turning shaft bracket 4, turning arms 6 are respectively connected to both ends of the turning shaft 5, and a glass grabbing plate 7 is connected between the two turning arms 6, and the glass grabbing Plate 7 is provided with a vacuum suction cup that grips the glass. The tray lifting mechanism includes a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com