Flotation column feeding system

A flotation column and ore feeding technology, which is applied in flotation, solid separation, etc., can solve problems such as easy blockage of branch pipes, inconvenient installation work, and installation accuracy that cannot meet the requirements, so as to achieve convenient maintenance and replacement, easy installation accuracy, Effect of Controlling Mounting Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

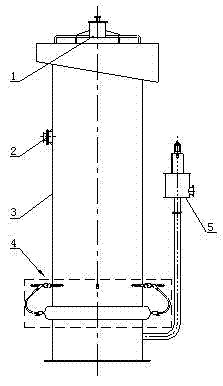

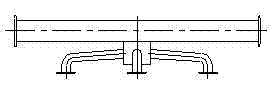

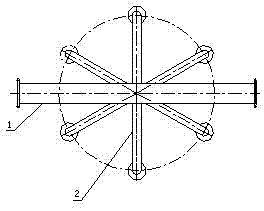

[0019] see Figure 4 , The flotation column feeding system of the present invention comprises a feeding pipe 6, a plurality of pulp outflow pipes 7, a fixing bracket 8 of the feeding pipe, a flange 9 of the feeding pipe, a casing flange 10 and a casing 11 of the feeding pipe; The ore feeding pipe 6 is horizontally inserted into the column body of the flotation column, and the ore slurry is introduced into the flotation column, and is fixed to the column through the connection between the ore pipe flange 9 and the casing flange 10, so as to prevent the entire ore feeding system from rotating, Vibration and swing phenomenon; multiple pulp outflow pipes 7 are arranged on the pipe wall of the ore feeding pipe 6, and multiple ore pulp outflow pipes 7 are arranged obliquely on the ore feeding pipe 6, and multiple ore pulp outflow pipes 7 are distributed on the ore feeding pipe On the wall, the even distribution of the slurry in the mine pipe is realized.

[0020] The ore pipe fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com