Automatic cover flipping structure of micro-centrifugal tube

A centrifuge tube and lid technology, which is applied in the field of automatic capping structure of microcentrifuge tubes, can solve the problems of time-consuming, labor-intensive and time-consuming to open the cap, and achieve the effect of saving time and convenient opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

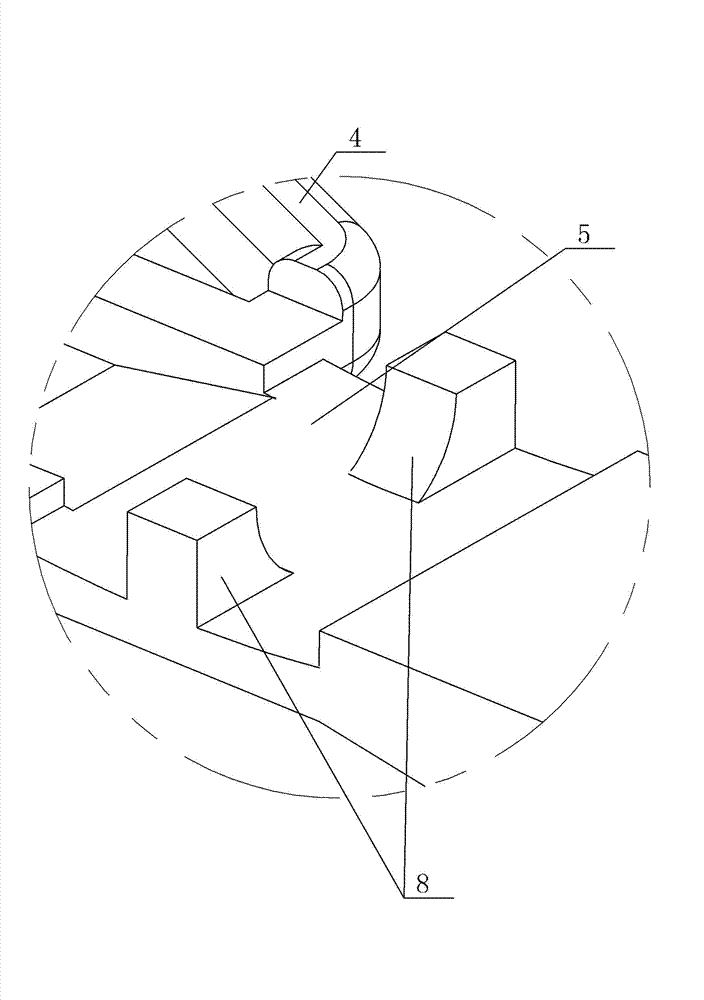

[0009] See figure 1 , figure 2 , which includes a cover 1 and a tube body 2, the cover 1 is mounted on the inner wall of the nozzle 3 of the tube body 2, the outer ring surface 9 of the cover 1 and the inner wall of the nozzle 3 are fitted with an interference fit, and the connecting part of the cover 1 4 Installed on the connecting end 5 of the tube body 2 through the rotating shaft, the outer ring surface of the nozzle 3 is provided with an outer edge positioning protrusion 6, and the cover 1 is provided with a lock 7 at the corresponding position of the outer edge positioning protrusion 6, and is locked. The lock 7 in the locked state is tightly fastened to the lower end surface of the outer edge positioning protrusion 6, and the connecting end 5 of the pipe body 2 is provided with two upward raised structures 8 near the nozzle 3, and the raised structures 8 in the locked state 8 is top mounted on the lower end surface of the corresponding position of the connecting part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com