Zipper assembly device of auto-end-closing injection machine and zipper assembly method of zipper assembly device

An injection molding machine, automatic technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of limited use range, low chain closing efficiency, inconvenient use, etc., to shorten production time and chain closing speed. The effect of high and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

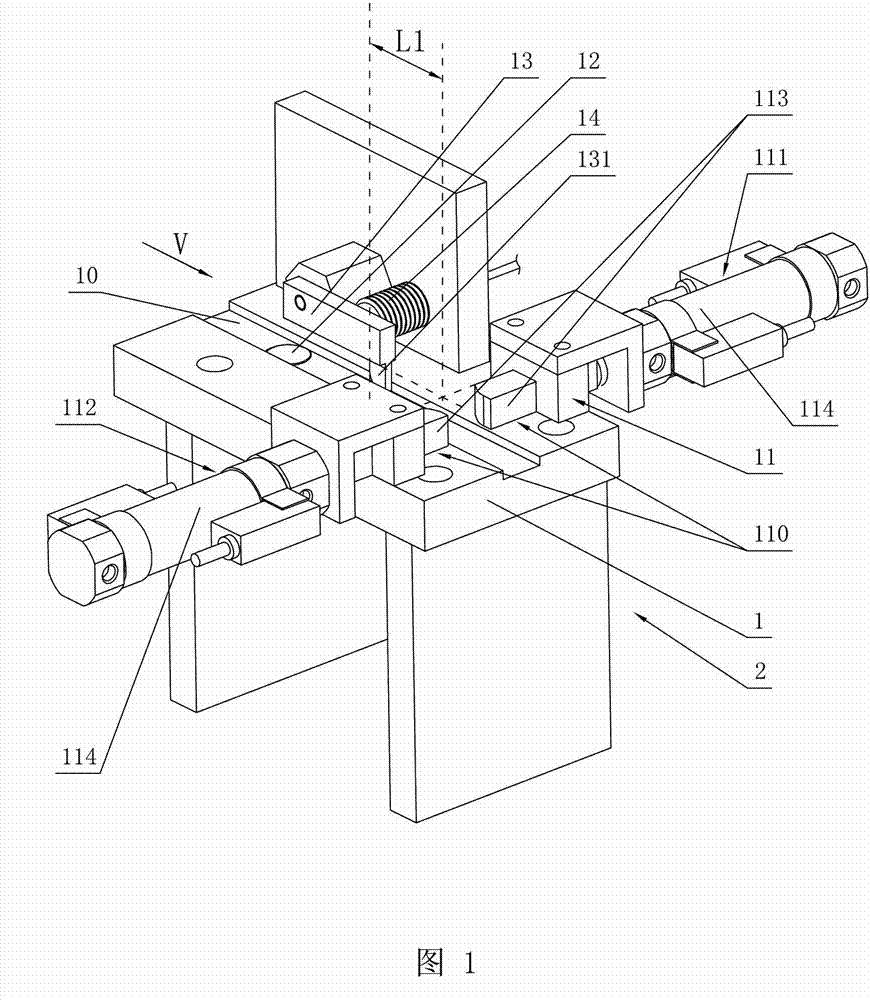

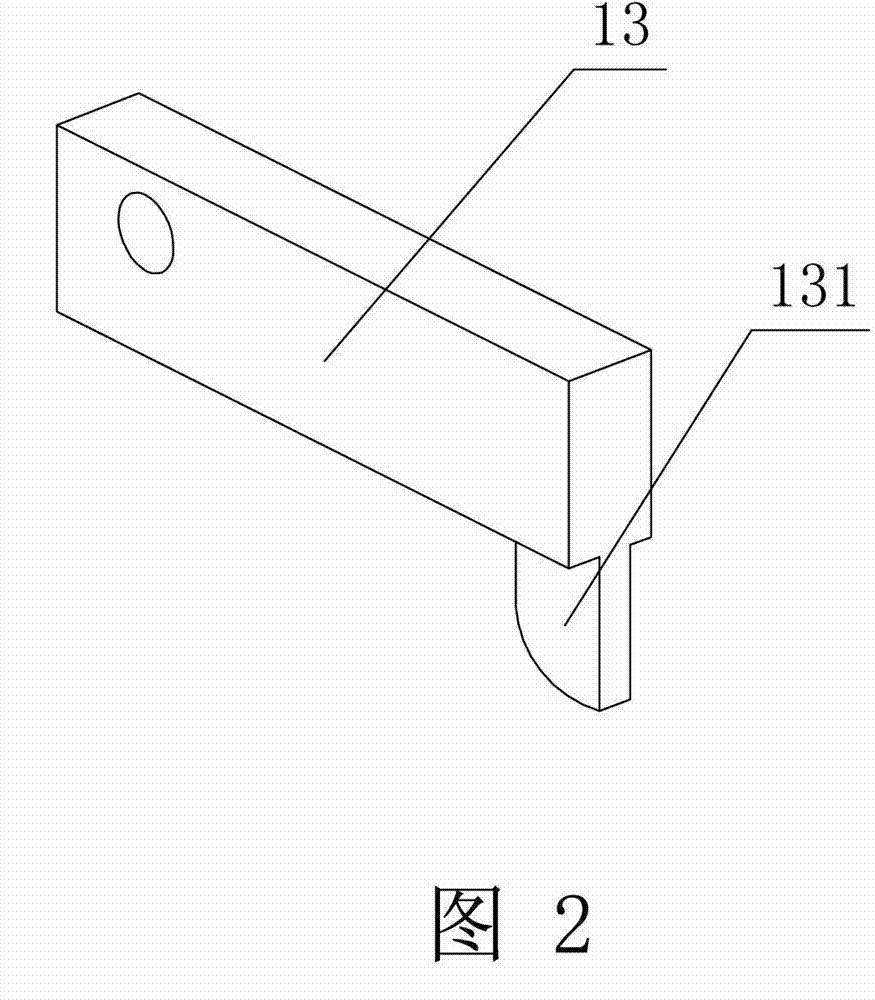

[0021] refer to figure 1 , figure 2 , the chain closing device of the automatic closed injection molding machine, including a main frame body 2 with a workbench 1, a guide groove 10 for directional sliding of the slider, and a pull belt for driving the zipper to slide along the guide groove 10 on the workbench 1 device and a chain closing mechanism 11, the chain closing mechanism 11 includes a left push arm 111 and a right push arm 112 respectively equipped with a driver 114, the left push arm 111 and the right push arm 112 are distributed on both sides of the guide groove 10, the workbench 1 is also provided with a slider sensor 12 for sensing the passage of the slider, a swing rod 13 for freely swinging up and down around an axis arranged above the guide groove 10, and a swing rod sensor 14 for sensing the swing of the swing rod 13. The zipper length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com