Multifunctional adjustable self-closing buffer hinge

An adjustable, self-closing technology, used in folding panels, door/window fittings, hinges with pins, etc., can solve the problems of kinetic energy accumulation, impact force, occupying too much space, and being inhumane enough to achieve torque that can be set. The effect of stable, beautiful appearance and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

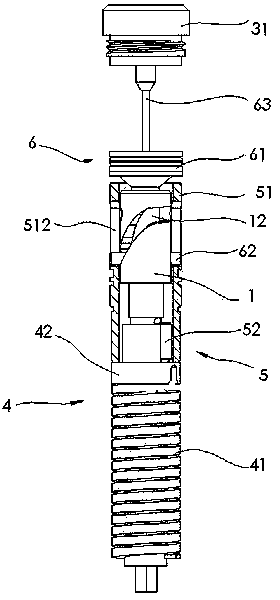

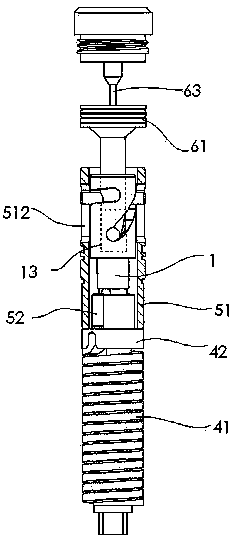

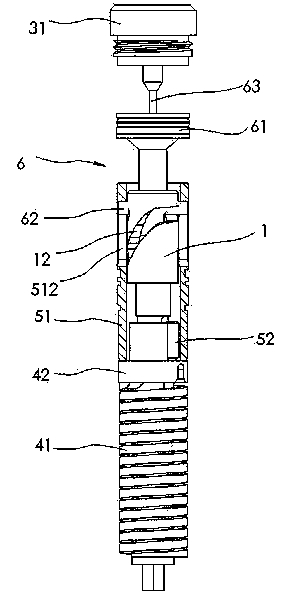

[0044] Embodiment 1: as Figure 1~3 As shown, a multifunctional adjustable self-closing buffer hinge includes a main shaft 1, a leaf 2 and a leaf 2 3 provided with a rotating tube, a lower end cover 21 and an upper end cover 31, and the main shaft 1 is provided with an elastic transmission Device 4, clutch 5 and damper 6, wherein:

[0045] Elastic transmission device 4 comprises the helical spring 41 that one end is fixedly connected with the lower end of main shaft 1 and the other end is connected with the turntable 42 that is located at the inner upper end of sheet-2 rotating tube, and turntable 42 is sliding fit with main shaft 1, and the lower end of main shaft 1 It is an oblate structure, and the oblate structure utilizes the oblate hole located at the center of the lower end cover 21 to be fixedly connected to the lower end of the sheet-2 rotating tube; the oblate structure is provided with a right-angled notch 11 to connect with the coil spring 41 lower ends are connec...

Embodiment 2

[0056] Embodiment 2: The helical groove on the main shaft 1 has a turning arc section 121 at a position of 5° to 10° from the lower end of the spiral groove, and the lift of the turning arc section is smaller than the lift of the rest of the helical groove; Due to the small lift of the turning arc section, the relative movement of the sliding kingpin in the turning arc section is accelerated when the door is closed. This acceleration causes the door to obtain a local impact force to achieve the effect of automatic locking of the door lock, such as Figure 11 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com