Alcohol production process

A technology for ethanol and alcohols, which can be used in microorganisms, biochemical instruments, biofuels, etc., and can solve the problem of high energy consumption for alcohol recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

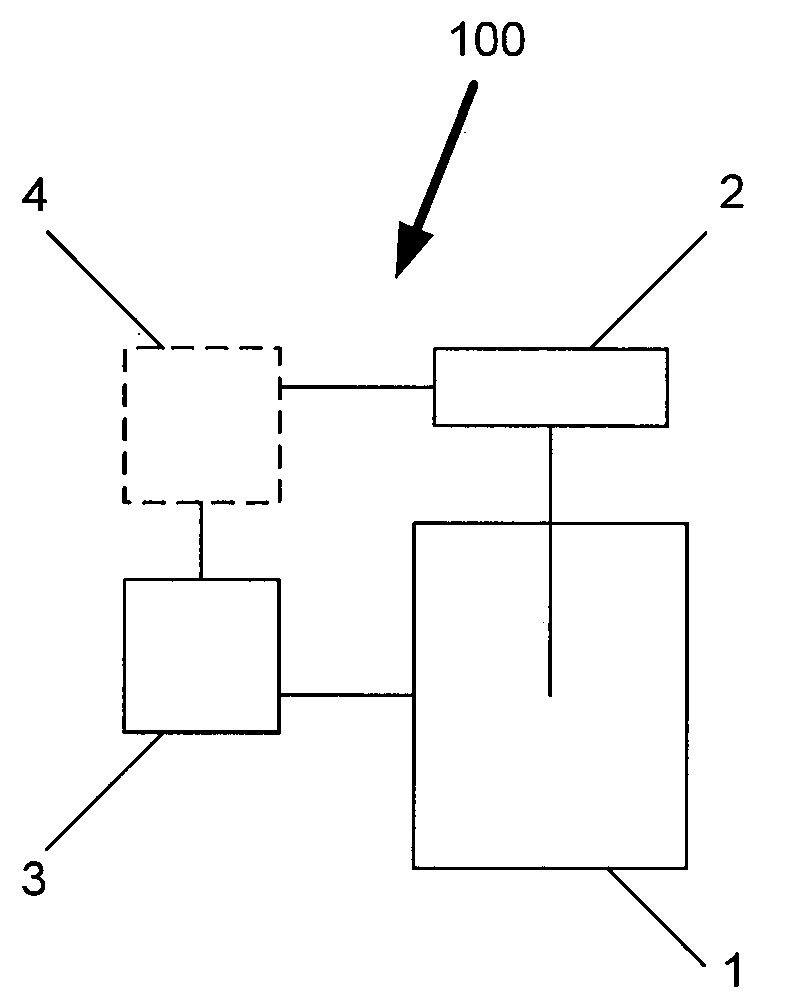

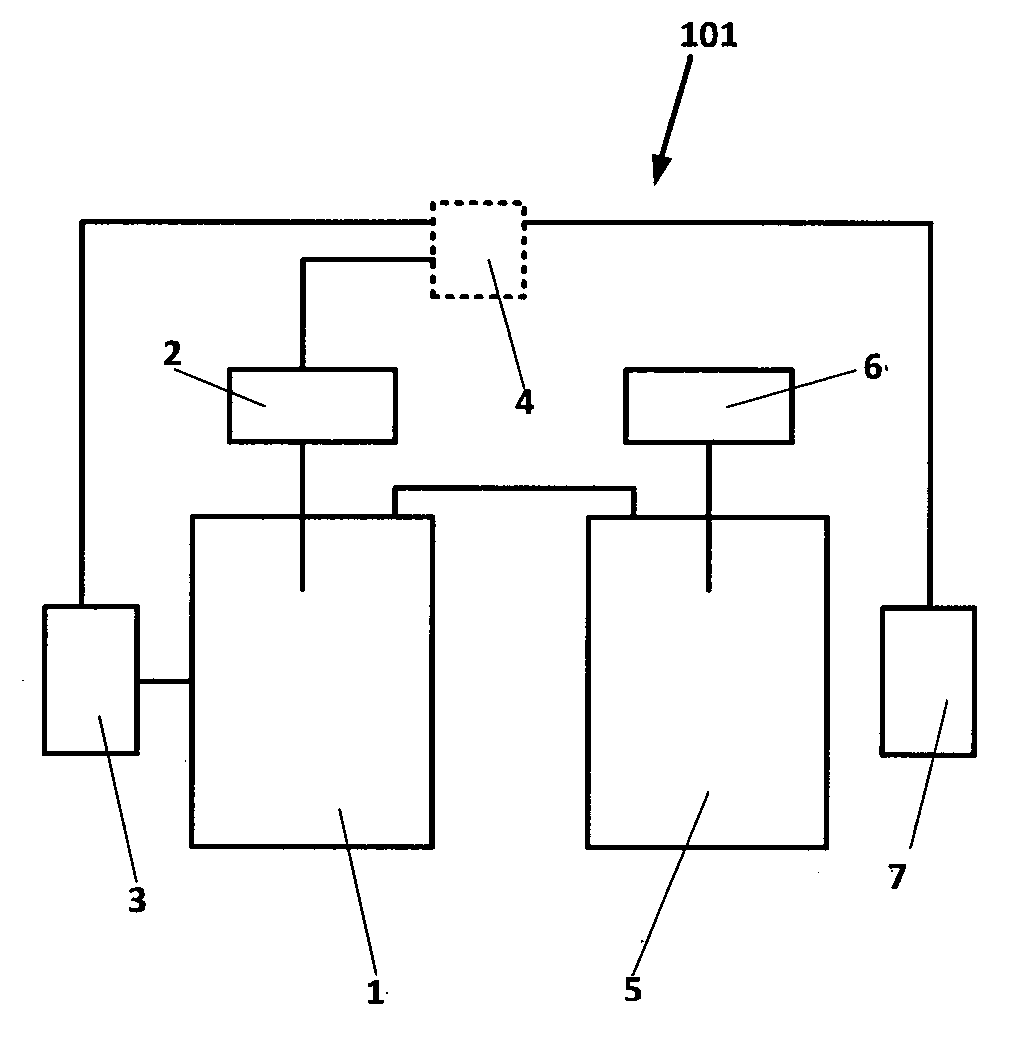

Method used

Image

Examples

Embodiment 1

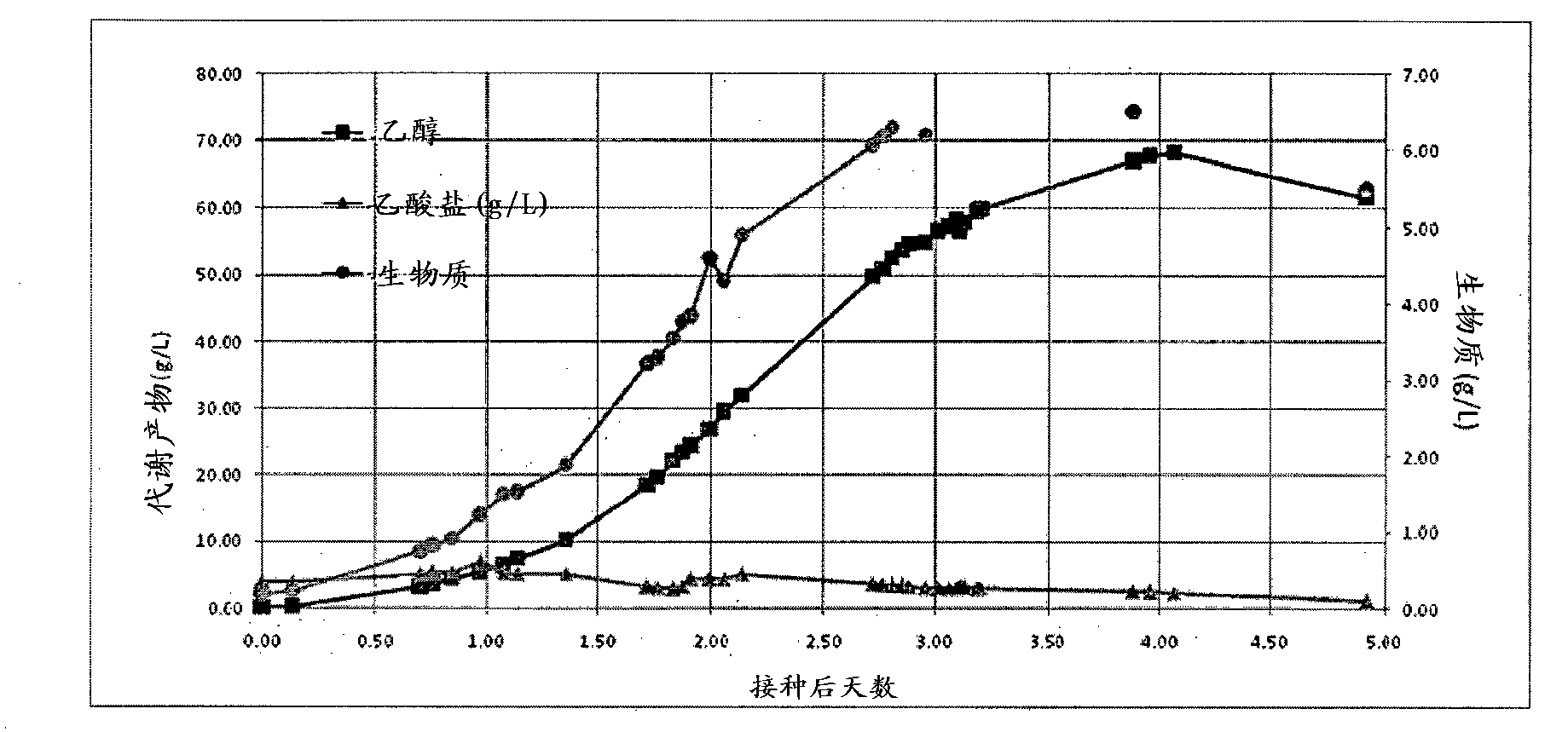

[0120] Example 1: Batch fermentation in CSTR

[0121] Solution A

[0122] NH 4 Ac 3.083g KCl 0.15g

[0123] MgCl 2 .6H 2 O 0.61g NaCl 0.12g

[0124] CaCl 2 .2H 2 O 0.294g distilled water up to 1L

[0125] Solution B

[0126]

[0127] Solution C

[0128]

[0129] Preparation of Cr(II) solution

[0130] A 1 L three-necked flask was fitted with gas-tight inlet and outlet to allow working under inert gas and subsequent transfer of the desired product to a suitable storage flask. The flask was filled with CrCl 3 .6H 2 0 (40g, 0.15mol), zinc particles [20 mesh] (18.3g, 0.28mol), mercury (13.55g, 1mL, 0.0676mol) and 500mL of distilled water. use N 2 After purging for 1 hour, the resulting mixture was heated to about 80° C. to start the reaction. at constant N 2 After stirring under flow for 2 hours, the mixture was cooled to room temperature and stirring was continued for 48 hours, at which point the reaction mixture became a dark blue...

Embodiment 2

[0139] The alcohol tolerance of Clostridium autoethanogenum DSM23693 was tested in serum bottles ( Figure 5 ). Ethanol was added at various concentrations to cultures actively growing at 37 °C in PETC medium (Table 1) with 30 psi steel plant gas (approximately 48% CO, 32% N 2 , 2%H 2 and 18%CO 2 ) as a substrate. By HPLC using an Agilent 1100 series HPLC system equipped with a RID (refractive index detector) operated at 35°C and an Alltech 10A-2000 organic acid column (150 x 6.5mm, particle size 5 μm) maintained at 60°C Analyze ethanol concentration. Use slightly acidified water (0.005MH 2 SO 4 ) as mobile phase, the flow rate is 0.7ml / min. To remove proteins and other cellular residues, 400 μl samples were mixed with 100 μl of 2% (w / v) 5-sulfosalicylic acid and centrifuged at 14,000 x g for 3 minutes to separate precipitated residues. Then 10 μl of the supernatant was injected into the HPLC for analysis.

[0140] At the lowest alcohol concentration (0.2 g / L, where n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com