Chemical processes generating solid (s) carried out continuously within microreactors

A micro-reactor, solid-state technology that can be used in the continuous field to solve problems such as unrevealed possibilities, and achieve the effects of flexible scaling, controlled thermal management, and precise stoichiometric ratio control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

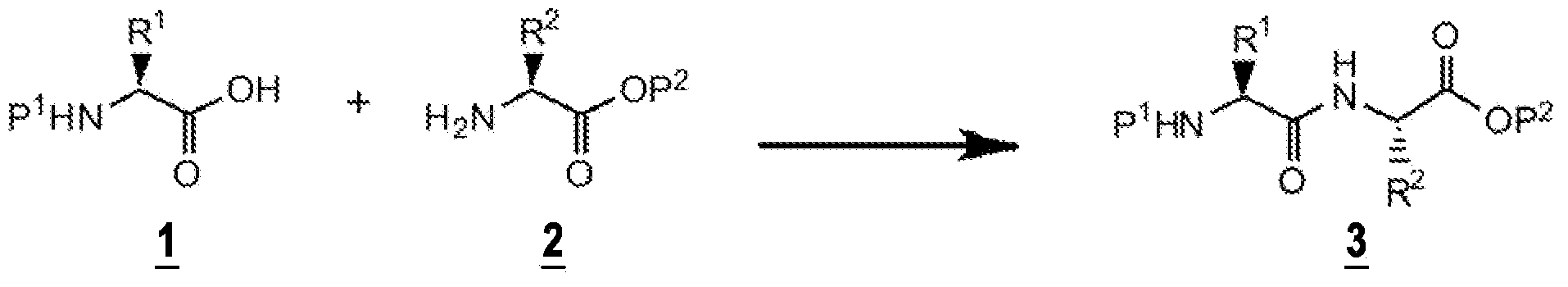

Method used

Image

Examples

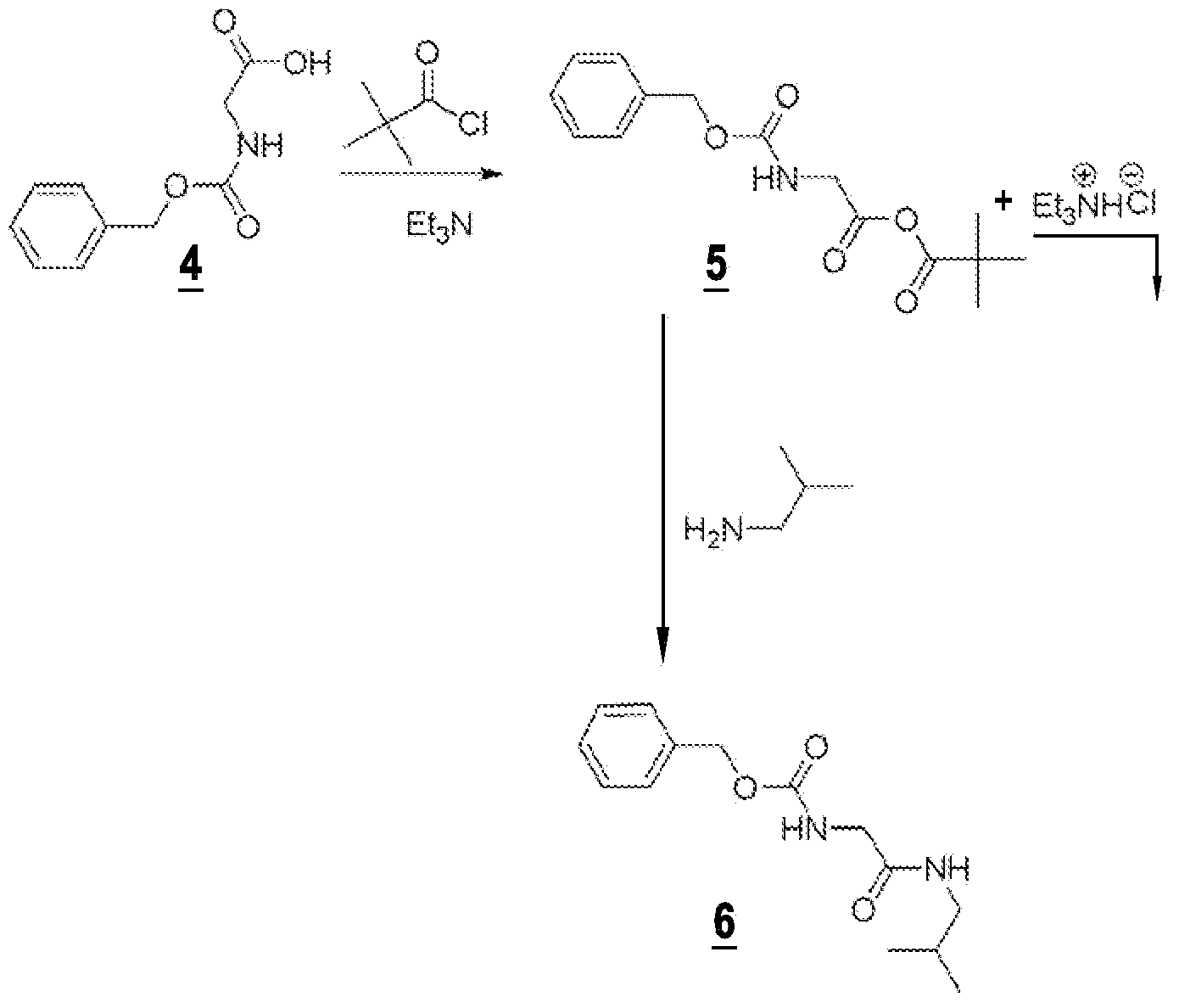

Embodiment 1

[0085] Solution A1: 10.5 g of Z-Gly-OH and 32.1 mL of triethylamine (0.4M amino acid) dissolved in 93 mL of toluene

[0086] Solution B1: 7.4 mL of trimethylacetyl (pivaloyl) chloride (0.4 M) dissolved in 143 mL of toluene

[0087] Solution C1: 200 ml water

[0088] Solution D1: 12 ml of isobutylamine (0.6M) dissolved in 200 ml of toluene.

[0089] In said Example 1, S1=toluene and S2=water.

Embodiment 2

[0091] Solution A2: 10.5 g of Z-Gly-OH and 32.1 mL of triethylamine (0.4 M amino acid) dissolved in 93 mL of ethyl acetate

[0092] Solution B2: 7.4 mL of trimethylacetyl (pivaloyl) chloride (0.4 M) dissolved in 143 mL of ethyl acetate

[0093] Solution C2: 200 ml of water containing 10% by weight of NaCl.

[0094] Solution D2: 12 ml of isobutylamine (0.6M) dissolved in 200 ml of ethyl acetate.

[0095] In said Example 2, S1 = ethyl acetate and S2 = water containing NaCl.

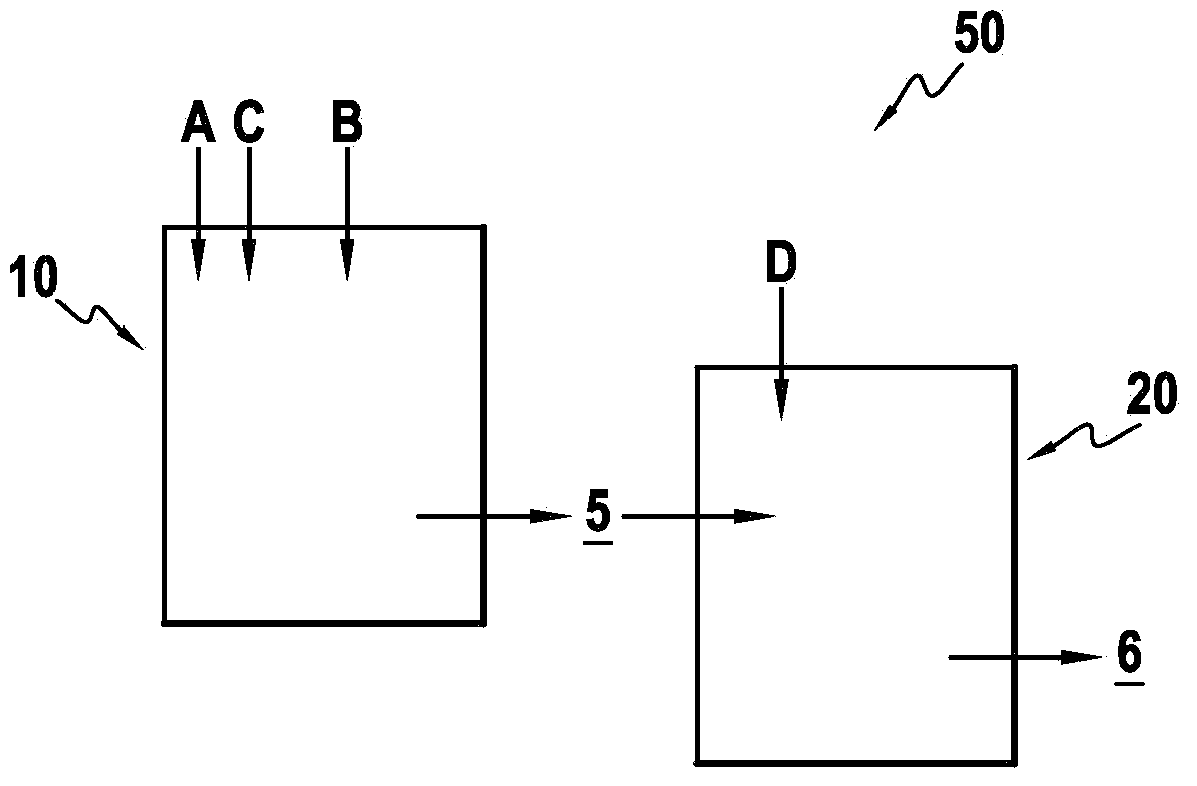

[0096] Flow rate and experimental setup

[0097] Solution A (A1 (Example 1) and A2 (Example 2)) and Solution B (respectively B1 and B2) were mixed with solution C (respectively C1 and C2) at a flow rate of 10 g / min (flow rate 15 g / min) are pumped into the non-mixing fluid compartment 10 together, and the temperature of the fluid compartment 10 is maintained at 5-10°C. In this compartment 10 the activated ester of Z-Gly is formed. The reaction was then quenched in the second mixing fluid chamber 20 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com