Measuring method for performance of foaming agent

A measuring method and technology for foaming performance, applied in the field of petroleum industry, can solve the problems such as the inability to objectively measure the high-temperature blocking ability of the foaming agent, the inability to measure the foam resistance factor, etc.

Inactive Publication Date: 2013-01-02

CHINA UNIV OF PETROLEUM (BEIJING)

View PDF7 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method can also be extended to the determination of the resistance factor of the foam at a high temperature of 300 ° C, but it cannot be determined for the resistance factor of the foam in the porous medium during the temperature change process

Therefore, the resistance factor at a single temperature point cannot objectively measure the high-temperature plugging ability of the blowing agent during the actual temperature change process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0140] (1) Determination of foaming performance and foam stabilizing performance experimental results

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

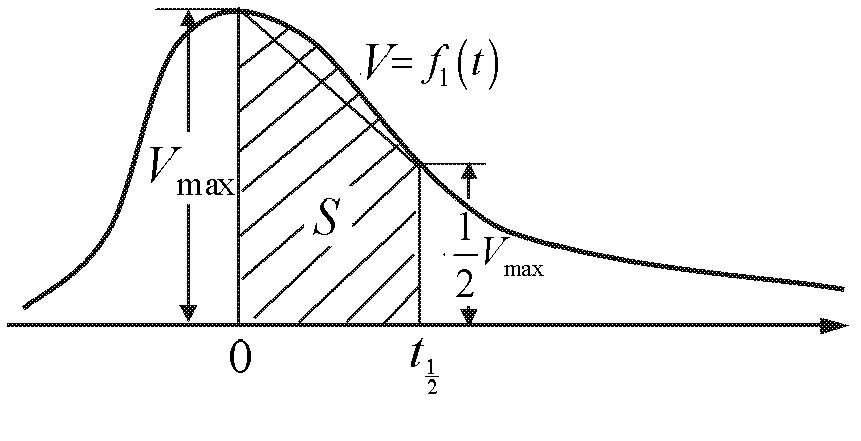

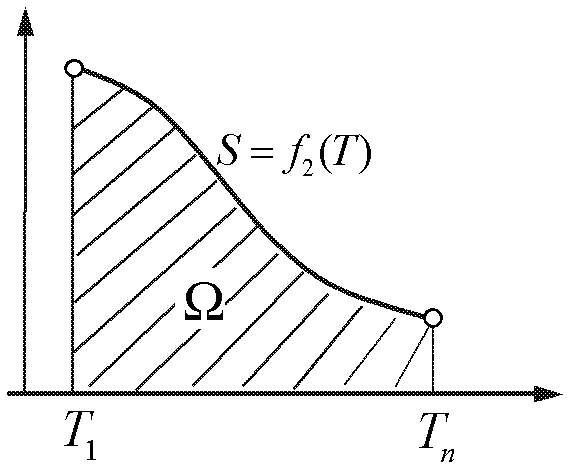

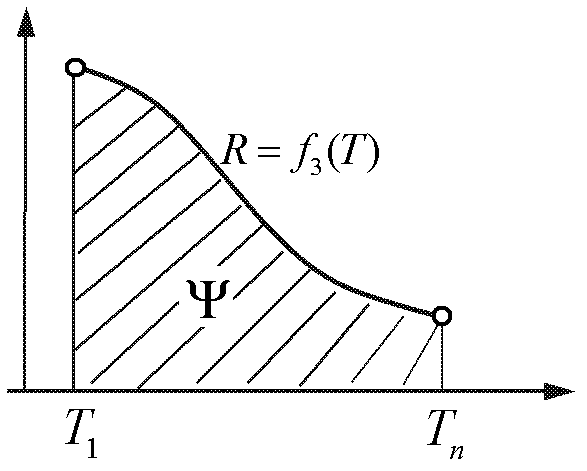

The invention belongs to the technical field of petroleum industry, relates to a measuring method for performance of foaming agent, specifically relates to measurement of high temperature performance of foaming agent. By measuring the foam volume and half-life of the foaming agent under different temperature conditions, the method obtains average foam comprehensive index as the measurement result of the foaming performance and foam stabilizing performance of the foaming agent; on this basis, by measuring the resistance factor of the foaming agent under different temperatures conditions, an average foam resistance factor is obtained to be used as the measurement result of the sealing and blocking performance of each foaming agent. The method can objectively measure the foaming performance, foam stabilizing performance and sealing and blocking performance of the foaming agent under varying temperature conditions, thus realizing the optimal selection of the foaming agent used for blocking and profile adjusting under high temperature vapor conditions on the site of oil field.

Description

technical field [0001] The invention belongs to the technical field of the petroleum industry, and relates to a method for measuring the performance of a foaming agent, in particular to a method for measuring the high-temperature performance of the foaming agent. Background technique [0002] Foam is a dispersion system formed by dispersing the gas phase in the liquid phase. This dispersion system is generally very unstable, and the stability of the foam generated by the liquid containing surfactant will be greatly enhanced. Foam systems are widely used in foam flooding in petroleum development, foam separation in environmental protection, foam flotation in metallurgical industry, fire extinguishing, daily cosmetics, food, etc. [0003] At present, there is no unified standard for the determination of foaming performance and foam stabilizing performance of high-temperature foaming agents. At home and abroad, the Waring Blender method or the Ross-Milles method is generally u...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N33/00

Inventor 庞占喜刘慧卿张红玲

Owner CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com