Dynamic test stand of backstop

A dynamic detection and backstop technology, which is applied in the testing of machines/structural components, mechanical components, instruments, etc., can solve problems such as unreliable backstop, potential safety hazards, unreliable backstop operation, etc., and achieve backstop Only reliable, good overall performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

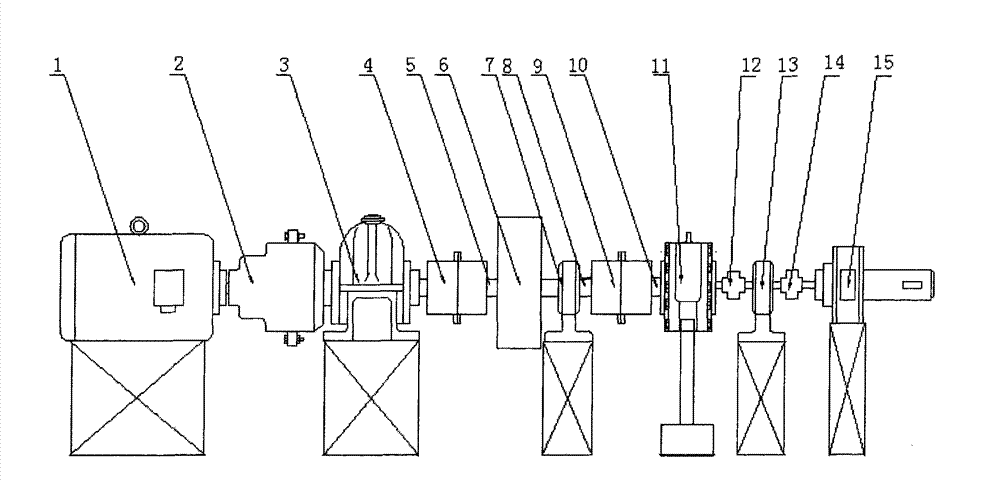

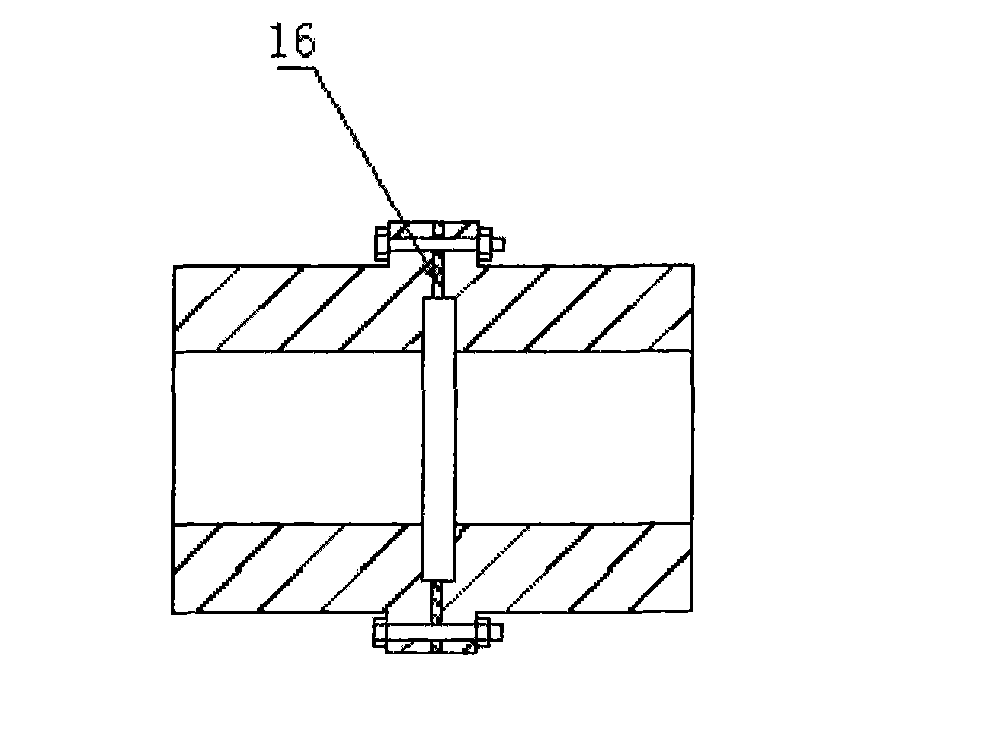

[0026] Such as figure 1 As shown, the backstop dynamic detection test bench of the present invention is mainly composed of a motor 1, a torque-limiting coupling 2, a reducer 3, a safety coupling 4, a mandrel 5; a clutch 6, a bearing seat 7, a mandrel 8, a convex Edge coupling 9, backstop mandrel 10, backstop 11, flange coupling 12, bearing seat 13, elastic coupling 14, speed regulating motor 15, etc.

[0027] The backstop dynamic detection test bench of the present invention has the connection sequence as follows: motor 1 is connected to the torque limiting coupling 2, the torque limiting coupling 2 is connected to the reducer 3, the reducer 3 is connected to the safety coupling 4, and the safety coupling 4 Connect the mandrel 5, the mandrel 5 is connected to the clutch 6, the clutch 6 is connected to the bearing seat 7, the bearing seat 7 is connected to the mandrel 8, the mandrel 8 is connected to the flange coupling 9, and the flange coupling 9 is connected to the backstop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com