Stable kiln liner of asphalt rotary kiln

A rotary kiln, stable technology, applied in the direction of rotary drum furnace, furnace type, furnace, etc., can solve the problems of unsatisfactory long service life, uncertain maintenance time, difficult disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

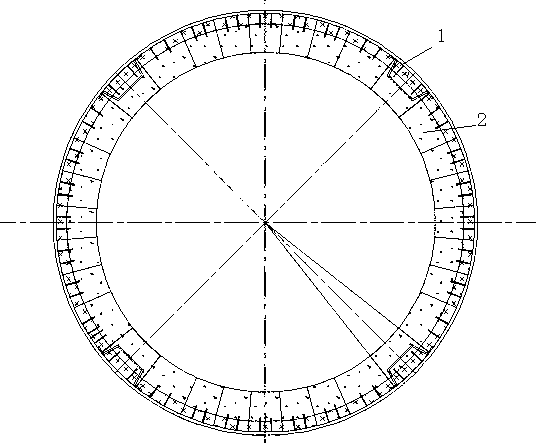

[0017] like figure 1 Shown: a stable asphalt rotary kiln kiln lining, which is divided into the kiln head cover to the transition section and the transition section to the kiln tail, the specific description is as follows:

[0018] Kiln head cover - transition section

[0019] See figure 1 The kiln lining of the rotary kiln adopts four fixed prefabricated blocks 1 distributed at 90° on the circumference, and adopts the welding form. Each fixed prefabricated block 1 adopts a socket design to ensure that it is anchored on the shell, so that each fixed prefabricated block and the kiln body steel plate form a whole. Build 8 prefabricated bricks 2 of about 20kg in the middle of every two fixed prefabricated blocks.

[0020] The advantages of this structure over double-layer castables are:

[0021] (1) Due to the fixed prefabricated blocks, the whole ring of bricks is divided into 4 parts, and the possible concentrated joints are 1 / 4 of the original ones, which greatly reduces t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com