Device and method for simulating thickened oil viscosity reduction during wellbore lifting

A simulation device and wellbore simulation technology, which is applied to earth-moving drilling, wellbore/well components, and production fluids, etc. It can solve the problem that the viscosity reduction effect varies greatly and cannot well show the dynamic effect of viscosity reducer and heavy oil. process and other issues to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

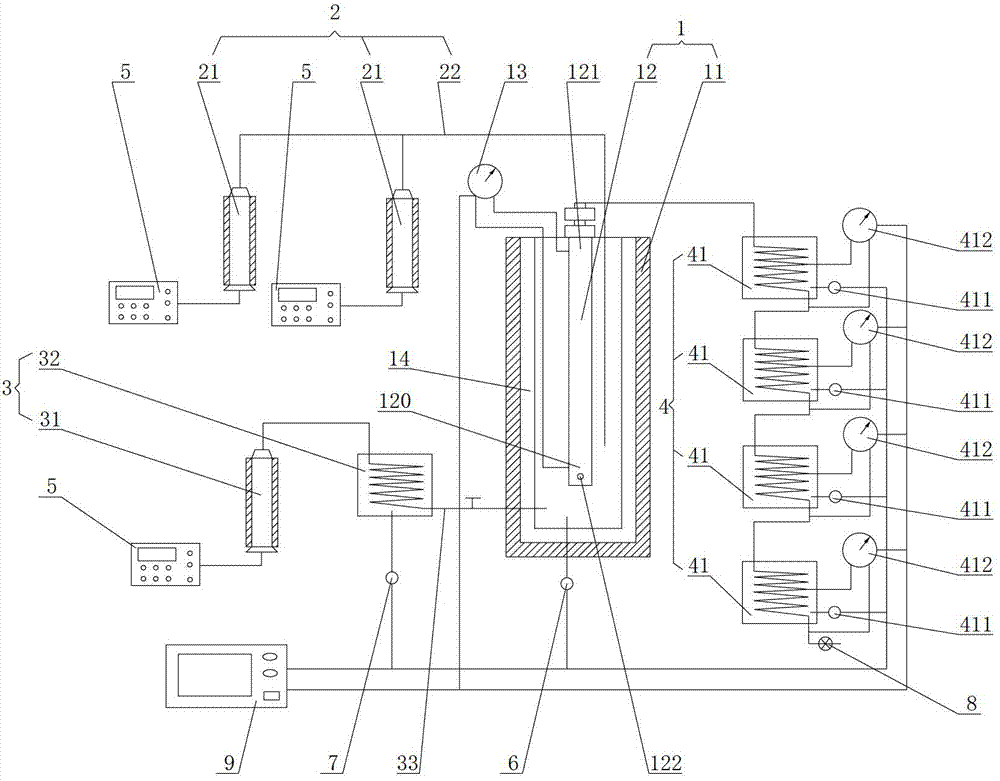

[0037] Such as figure 1 As shown, the present invention provides a heavy oil wellbore lift-viscosity simulation device, which includes a wellbore simulation system 1 , a dosing system 2 , a liquid supply system 3 and a monitoring and control system 4 . Wherein: the wellbore simulation system 1 has a simulated wellbore 11, the simulated wellbore 11 is provided with a simulated lifting string 12, and a pressure difference is connected between the liquid inlet 120 and the liquid outlet 121 of the simulated lifting string 12 The sensor 13; the dosing system 2 is connected with the wellbore simulation system 1, the dosing system 2 has a plurality of dosing piston containers 21, and the dosing piston containers 21 are respectively connected with a dosing pipe 22, the The dosing pipe 22 extends into the bottom of the simulated wellbore 11; the liquid supply system 3 is connected with the wellbore simulation system 1, and the liquid supply system 3 has a liquid supply piston container...

Embodiment approach 2

[0068]The present invention also provides a heavy oil wellbore lifting viscosity reduction simulation method, characterized in that the heavy oil wellbore lifting viscosity reduction simulation method adopts the heavy oil wellbore lifting viscosity reduction simulation device described in Embodiment 1, and the heavy oil The structure, working principle and beneficial effects of the wellbore lifting and lowering viscosity simulation device are the same as those in Embodiment 1, and will not be repeated here. The heavy oil wellbore lift-viscosity simulation method includes the following steps:

[0069] a) The viscosity reducer is output through the dosing system 2, and the thick oil is output through the liquid supply system 3;

[0070] b) The viscosity reducer and the heavy oil are jointly injected into the bottom of the simulated wellbore 11 of the wellbore simulation system 1, and mixed at the bottom of the simulated wellbore 11;

[0071] c) The mixed liquid generated after ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap