Pre-tensioned deformed reinforced concrete precast main beam

A technology of pretensioning and reinforced concrete, applied in the direction of joists, girders, truss beams, etc., can solve the problems of troublesome beam manufacturing, affecting the bending strength, and weakening of the compressive section, so as to reduce the self-weight, facilitate hoisting and transportation, and reduce the Effect of Lifting Capacity Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

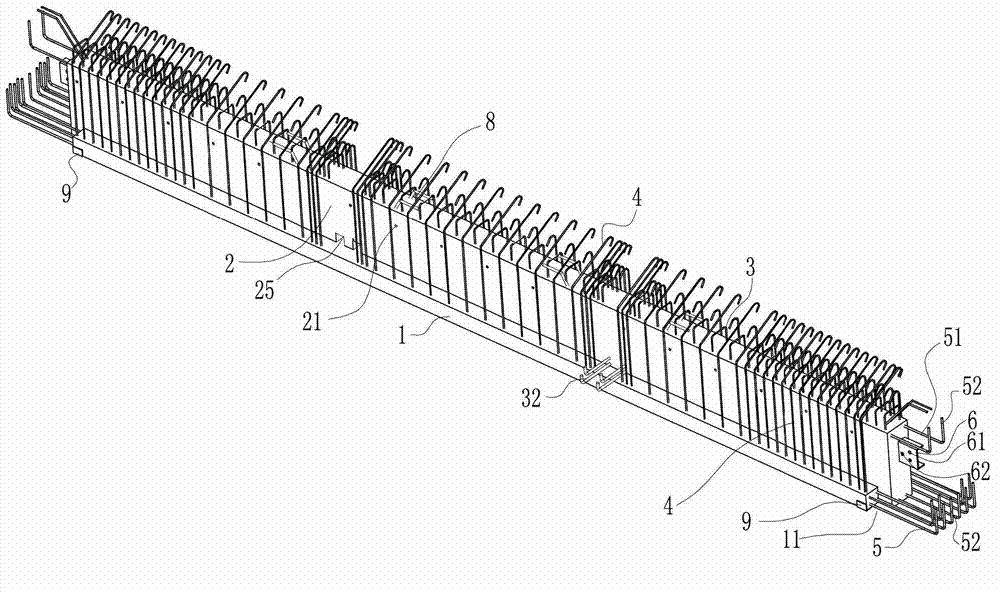

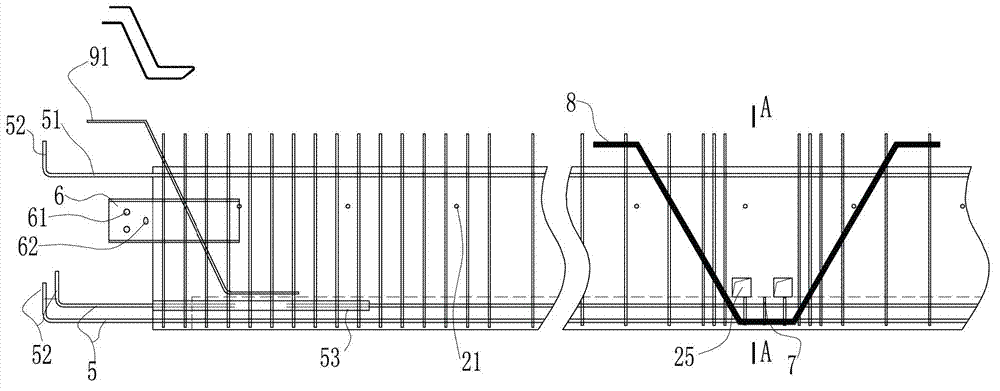

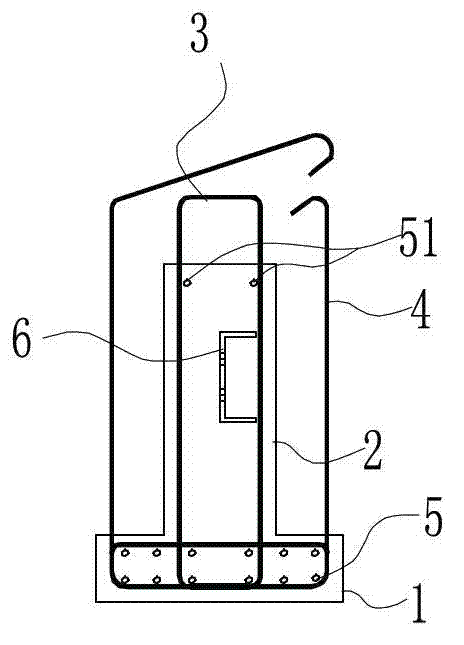

[0026] see Figure 1 to Figure 4 , in the embodiment of a pre-tensioned special-shaped reinforced concrete prefabricated main girder provided by the present invention, the girder body is an inverted T-shaped section composed of a horizontal rectangular compression part 1 and a vertical rectangular shear part 2, and the vertical The rectangular shear part 2 is embedded with a rectangular stirrup 3, and part of the rectangular stirrup 3 protrudes from the upper surface of the vertical rectangular shear part 2, and the horizontal rectangular compressive part 1 is embedded with a U-shaped stirrup 4. The upper part of the U-shaped stirrup 4 protrudes from the upper surface of the horizontal rectangular compression part 1 for a certain length, and the steel strand 5 is embedded in the horizontal rectangular compression part 1 . The present invention sets the prefabricated beam into an inverted T-shaped structure, in which the horizontal rectangular compression-resistant part 1 can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com