Hollow composite wall of a building frame structure

A frame structure and wall technology, which is applied to building components, building structures, buildings, etc., can solve the problems of poor wall heat insulation effect, prolonged wall completion time, and inability to achieve self-aligning seams, etc. High construction speed, enhanced anti-leakage performance, and the effect of preventing oblique cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

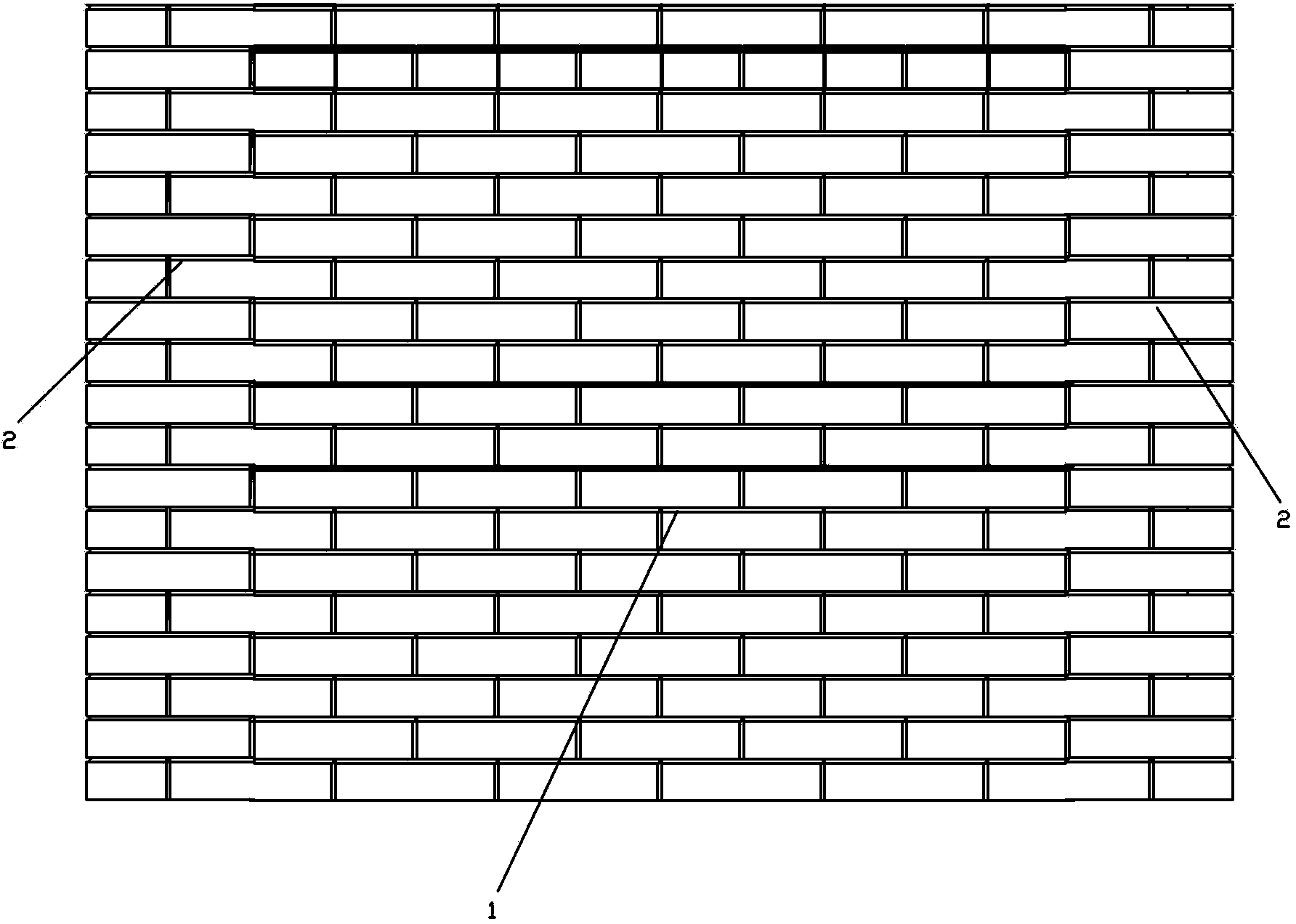

[0045] A hollow composite wall with a building frame structure, the hollow composite wall is built between a cement column 200 and a cement beam 201, it includes a main wall 1 and a decorative wall 2 attached to the cement column, the main wall The body 1 includes a laminated wall 10 and a topping layer 10A. The laminated wall 10 is formed of several layers of bricks 11, and is formed of several layers of bricks. The positions of the bricks 11 of the upper and lower adjacent layers are staggered from each other. Setting; the decorative wall 2 includes a single-panel brick 21 and a corner brick 22 with a right angle;

[0046] The bricks 11 used to build the stacked wall 10 include a first long side 111 and a second long side 112 arranged at a certain distance, and connect the first long side 111 and the second long side 112 Rib 113; the upper end of rib 113 is provided with limiting boss 114, the lower end of rib 113 is provided with limiting groove 115 matching with limiting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com