Safety protection device for rotation angle of rotary work table

A technology of safety protection device and rotating workbench, which is applied to the direction of workbench and manufacturing tools, and can solve the problems that the limit angle of rotation cannot be further expanded and the path is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable your examiner to have a better understanding of the present invention, hereby cite a preferred embodiment together with the accompanying drawings, and describe it in detail as follows:

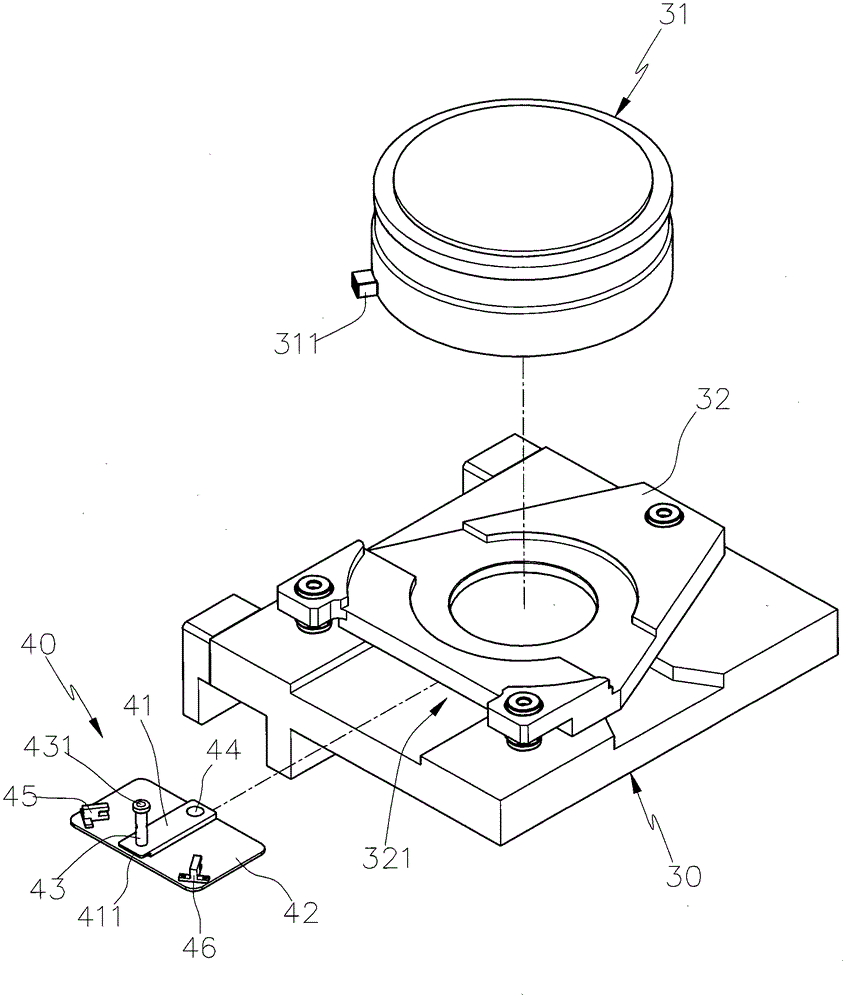

[0030] see image 3 , Figure 4 , the present invention includes a rotary table 31 located on the base 30 and a limit mechanism 40 located on the side of the rotary table 31. In this embodiment, the rotary table 31 is located on a base 32, and the base 32 is set on the base 30 again, wherein, the pedestal 32 is a stepped groove 321 on one side, and the limit mechanism 40 is partly concealed in the stepped groove 321 of the pedestal 32; A pusher 311 is provided, and a swing arm 41 is pivoted on the base 30 by the limit mechanism 40. In this embodiment, a bottom plate 42 fixed on the base 30 is provided, and a pivot 44 is pivoted on the bottom plate 42. Establish a swing arm 41, and on the swing arm 41 corresponding to the position of the pusher 311 of the rotary tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com