A lithium-ion battery diaphragm automatic retracting device

A lithium-ion battery, automatic winding technology, used in transportation and packaging, thin material processing, sending objects, etc., can solve the problems of irregular shape of the diaphragm, incomplete incision of the diaphragm, no incision of the diaphragm, etc., to achieve convenient operation. , to avoid the effect of incomplete cutting and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

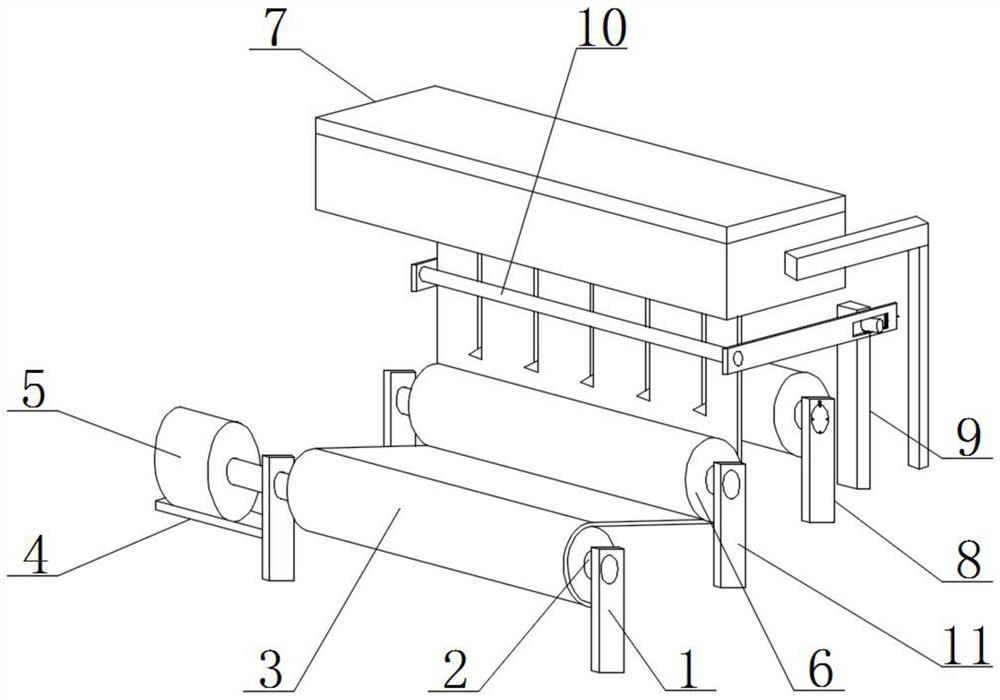

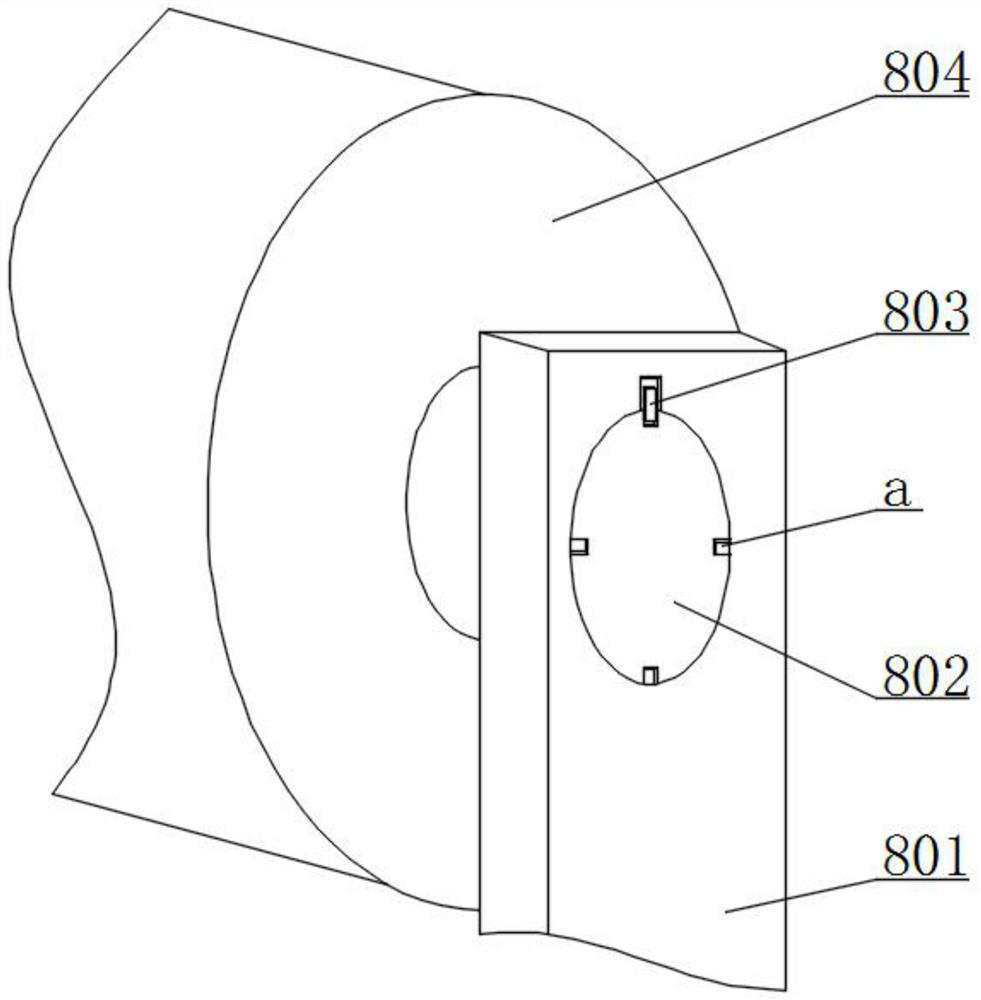

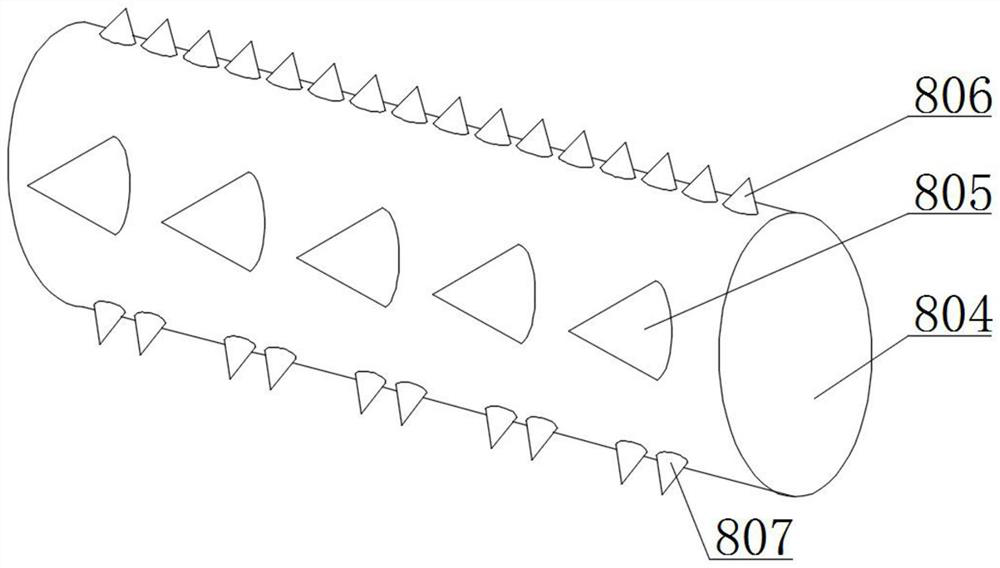

[0028] Example 1: See Figure 1-11 , the present invention provides a technical solution:

[0029]An automatic retracting device for a lithium-ion battery diaphragm, comprising a first bracket 1, a rotating shaft 2, a lithium-ion battery diaphragm 3 and a fixed plate 4, a rotating shaft 2 is rotatably connected above the right end surface of the first bracket 1 on the right side, and the rotating shaft 2. There is a lithium-ion battery separator 3 on the outside. This setting can ensure that the lithium-ion battery separator 3 will not wrinkle and ensure the quality of the lithium-ion battery separator 3. The left end of the first bracket 1 on the left is fixedly connected with a fixing plate 4, and the upper end surface of the fixed plate 4 is fixedly connected with the first motor 5, the end of the main shaft of the first motor 5 is fixedly connected with the rotating shaft 2, the fourth bracket 11 is arranged behind the first bracket 1, and the right end surface of the four...

Embodiment 2

[0032] Example 2: See Figure 1-11 , the present invention provides a technical solution:

[0033]An automatic retracting device for a lithium-ion battery diaphragm, comprising a first bracket 1, a rotating shaft 2, a lithium-ion battery diaphragm 3 and a fixed plate 4, a rotating shaft 2 is rotatably connected above the right end surface of the first bracket 1 on the right side, and the rotating shaft 2. There is a lithium-ion battery separator 3 on the outside. This setting can ensure that the lithium-ion battery separator 3 will not wrinkle and ensure the quality of the lithium-ion battery separator 3. The left end of the first bracket 1 on the left is fixedly connected with a fixing plate 4, and the upper end surface of the fixed plate 4 is fixedly connected with the first motor 5, the end of the main shaft of the first motor 5 is fixedly connected with the rotating shaft 2, the fourth bracket 11 is arranged behind the first bracket 1, and the right end surface of the four...

Embodiment 3

[0036] Example 3: See Figure 1-11 , the present invention provides a technical solution:

[0037]An automatic retracting device for a lithium-ion battery diaphragm, comprising a first bracket 1, a rotating shaft 2, a lithium-ion battery diaphragm 3 and a fixed plate 4, a rotating shaft 2 is rotatably connected above the right end surface of the first bracket 1 on the right side, and the rotating shaft 2. There is a lithium-ion battery separator 3 on the outside. This setting can ensure that the lithium-ion battery separator 3 will not wrinkle and ensure the quality of the lithium-ion battery separator 3. The left end of the first bracket 1 on the left is fixedly connected with a fixing plate 4, and the upper end surface of the fixed plate 4 is fixedly connected with the first motor 5, the end of the main shaft of the first motor 5 is fixedly connected with the rotating shaft 2, the fourth bracket 11 is arranged behind the first bracket 1, and the right end surface of the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com