Device and method for preparing pulsatile release microspheres

A pulsed release and microsphere technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problem that the microspheres cannot exhibit pulsed drug release behavior, and achieve strong controllability of the release behavior, low energy consumption, and drug release. High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

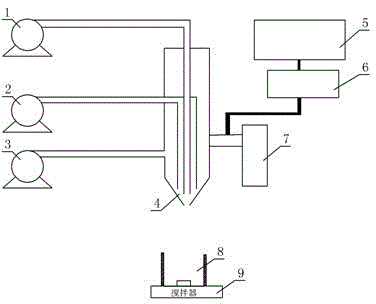

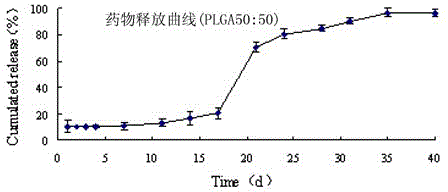

[0022] Example 1, the preparation device of pulse release microspheres figure 1 As shown, it includes: a constant flow pump 1, a constant flow pump 2, a constant flow pump 3, a coaxial nozzle 4, a frequency generator 5, a signal amplifier 6, an ultrasonic transducer 7, a collection container 8 and a stirrer 9. The coaxial nozzle 4 is a concentric three-port nozzle, in which the inner diameter of the inner nozzle is 100 μm And connected to the constant flow pump 1 through an independent liquid delivery pipeline, the inner diameter of the middle nozzle is 200 μm It is connected to the constant flow pump 2 through an independent liquid delivery pipeline, and the inner diameter of the outer nozzle is 400 μm It is connected to the constant flow pump 3 through an independent liquid delivery pipeline. A collection container 8 with a stirrer 9 is placed under the coaxial nozzle 4. The ultrasonic transducer 7 is connected to the coaxial nozzle 4, and the ultrasonic transducer 7 The syste...

Embodiment 2

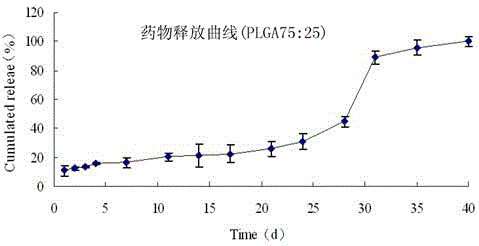

[0034] Example 2. The preparation device of pulse release microspheres is as figure 1 As shown, it includes: a constant flow pump 1, a constant flow pump 2, a constant flow pump 3, a coaxial nozzle 4, a frequency generator 5, a signal amplifier 6, an ultrasonic transducer 7, a collection container 8 and a stirrer 9. The coaxial nozzle 4 is a concentric three-port nozzle, in which the inner diameter of the inner nozzle is 100 μm And connected to the constant flow pump 1 through an independent liquid delivery pipeline, the inner diameter of the middle nozzle is 200 μm It is connected to the constant flow pump 2 through an independent liquid delivery pipeline, and the inner diameter of the outer nozzle is 400 μm It is connected to the constant flow pump 3 through an independent liquid delivery pipeline. A collection container 8 with a stirrer 9 is placed under the coaxial nozzle 4. The ultrasonic transducer 7 is connected to the coaxial nozzle 4, and the ultrasonic transducer 7 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com