Loop security automatic controlling system capable of resisting 30-degree angle error

A technology of automatic control system and differential loop, applied in the direction of information technology support system, power network operating system integration, circuit device, etc., can solve problems such as equipment damage, infeasibility, and reliability constraints of substation power supply, so as to achieve safe use, Improved power supply reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

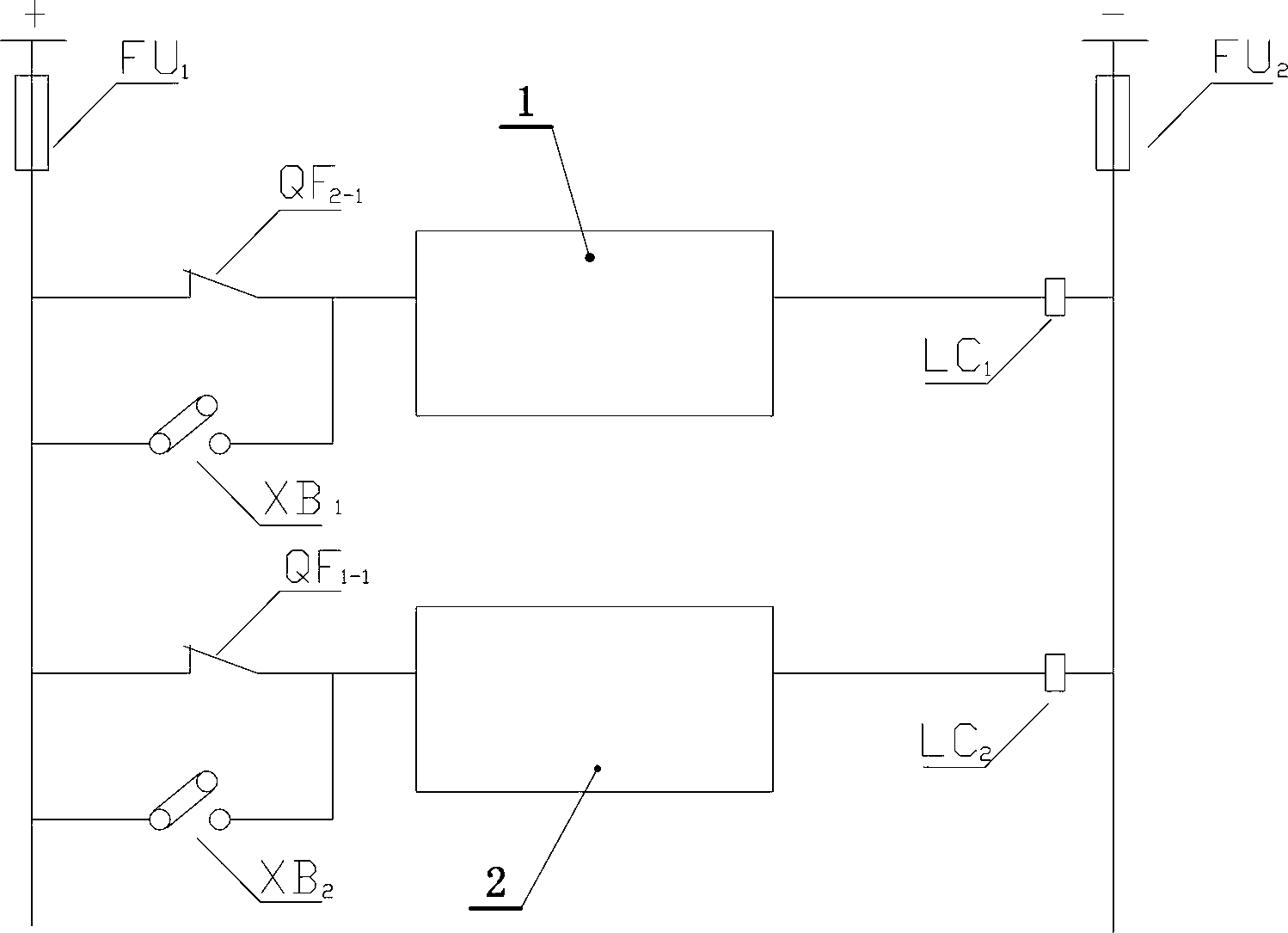

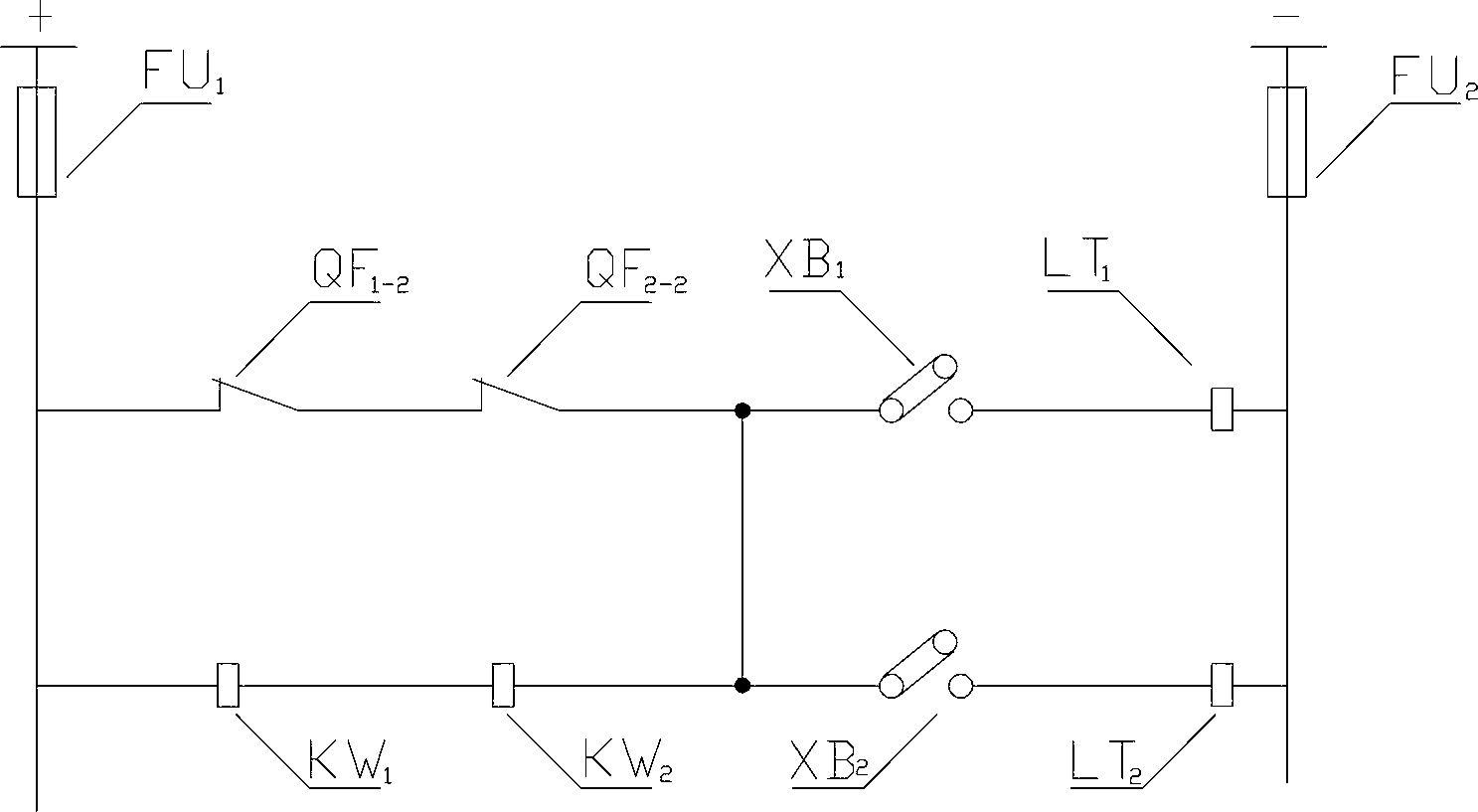

[0013] A loop safety automatic control system against 30° angle difference, such as figure 1 shown, the backup power switch auxiliary contact QF 2-1 , switch film XB 1 Parallel connection, and then with the main power supply closing control circuit, closing coil LC 1 Series connection; main power switch auxiliary contact QF 1-1 , switch film XB 2 Parallel connection, and then with the backup power supply closing control circuit, closing coil LC 2 Series connection; the DC power positive busbar is the same as the control power supply fuse FU 1 Connected in series, through the above two series circuits, and then through the control power supply fuse FU 2 , connected to the negative busbar of the DC power supply to form a closing circuit.

[0014] Under normal circumstances, the main power supply runs with a substation, and the auxiliary contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com