Sticky wax groove

A technology of sticking wax and grooves, which is applied in the direction of optical components, optics, instruments, etc., can solve the problems of coating peeling, waste of energy, defects, etc., and achieve the effect of reducing damage and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

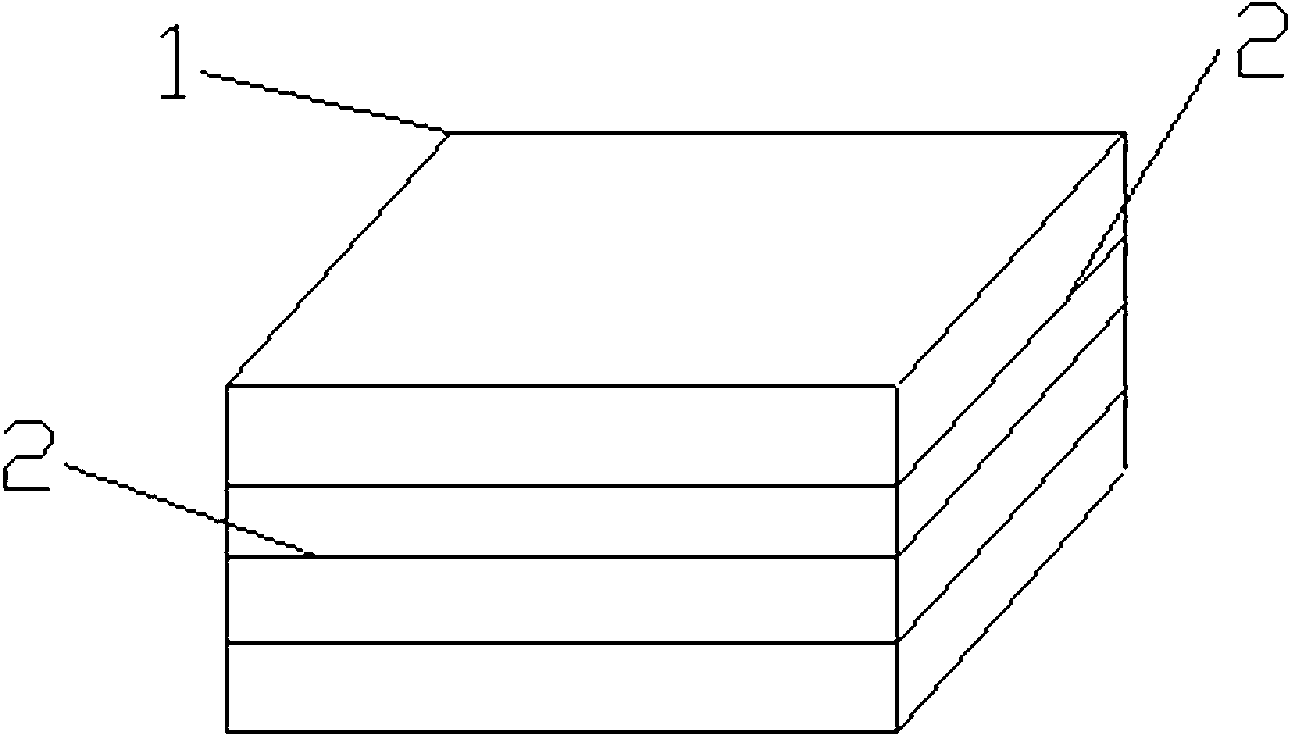

[0014] As shown in the drawings, the wax sticking tank of the present invention includes a tank body 1 with an open top, and heating pipes 2 are uniformly arranged on the four walls and the bottom surface of the tank body 1 .

[0015] When in use, put the wax block into the tank body 1, and the heating tube 2 heats the five sides of the tank body. Since the tank body is heated more evenly, the temperature of each area of the wax liquid does not need to be too much higher than the melting point of the wax to ensure that all The wax remains molten, reducing damage to the lens.

[0016] Further, the heating tubes 2 on the four walls and the bottom surface are integrally formed to form an integral pipeline, which facilitates uniform heating of the heating tubes, making the tank body heated evenly and easy to control; and connecting the heating tubes to a PLC temperature controller, when the tank body When the temperature is too high, the heating can be automatically cut off, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com