Normal temperature large-caliber flue gas pipeline inlet sealer for cement industry

A pipeline import, cement industry technology, applied in the direction of lifting valves, engine components, mechanical equipment, etc., can solve the problems of inability to meet low leakage requirements, large leakage rate of ventilation butterfly valves, high cost of driving components, etc., to achieve reduced opening force and sealing performance Good, the effect of reducing the output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

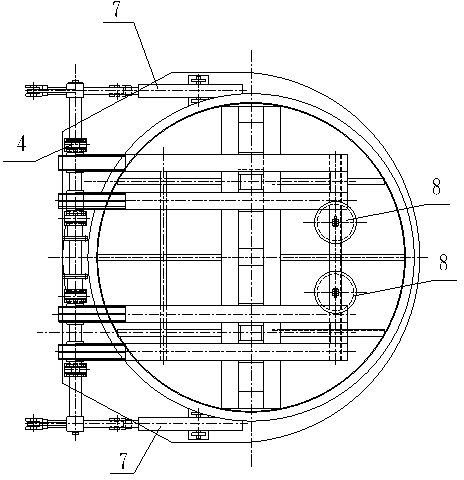

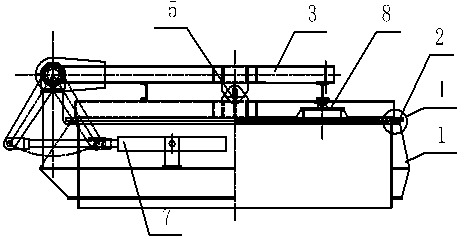

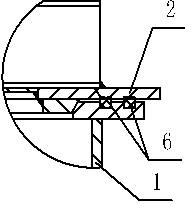

[0014] Such as figure 1 , 2 Shown in and 3: an airtight device for the inlet of a large-diameter flue gas pipeline at room temperature for the cement industry, including a valve body 1, a valve cover 2, a force arm assembly 3, a supporting part 4, a pin shaft 5, a seal 6, a driving part 7 and The pressure relief part 8, the inner opening of the valve body 1 is provided with a sealing slope, the upper end surface of the valve body 1 is provided with a mounting groove, and a sealing member 6 is provided in the mounting groove, and the valve cover 2 is connected to the arm assembly 3 through the pin shaft 5 Connection, the pin shaft 5 holes are U-shaped pin holes, the pressure relief component 8 is installed on the valve cover 2, the pressure relief component 8 includes the pressure relief component valve cover, the pressure relief component valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com