Construction method for steel structure truss of super high-rise special structure

A construction method and a technology of structural steel, which is applied in the direction of building construction, construction, and building material processing, etc., can solve the problem of narrow tower crane performance steel structure installation progress in the component stacking site, high risk of heavy-duty structure hoisting, and difficulty in positioning special-shaped structures, etc. problems, to achieve the effect of strong reliability of construction quality, control of construction quality, and fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with specific examples.

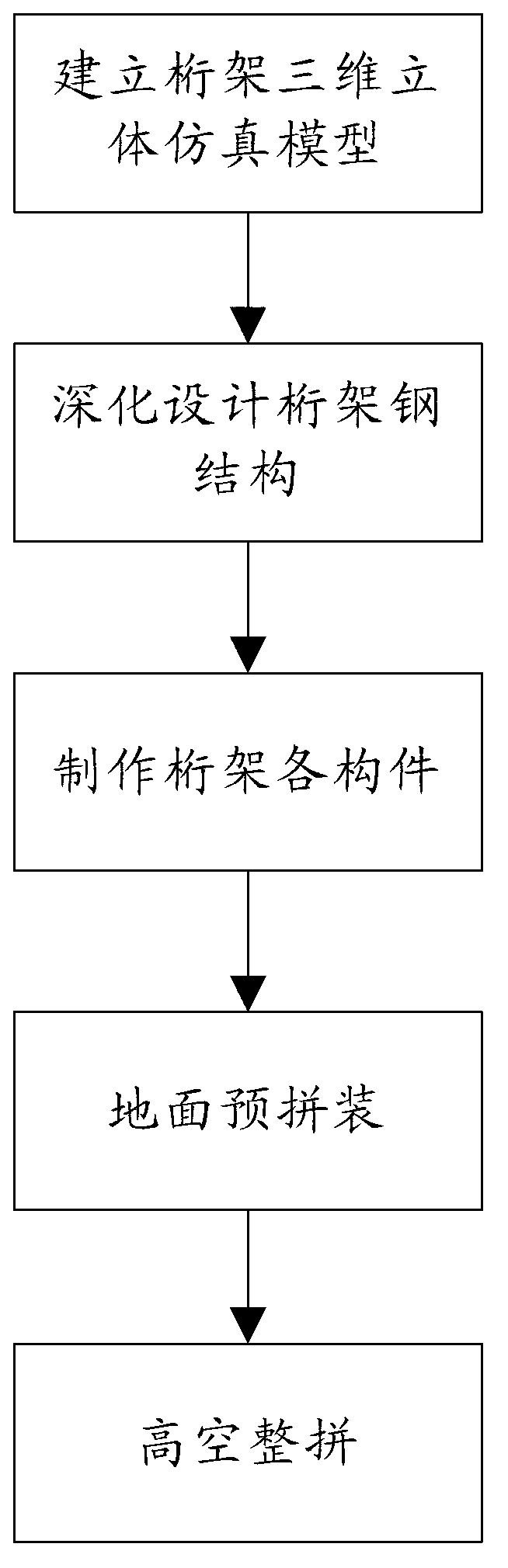

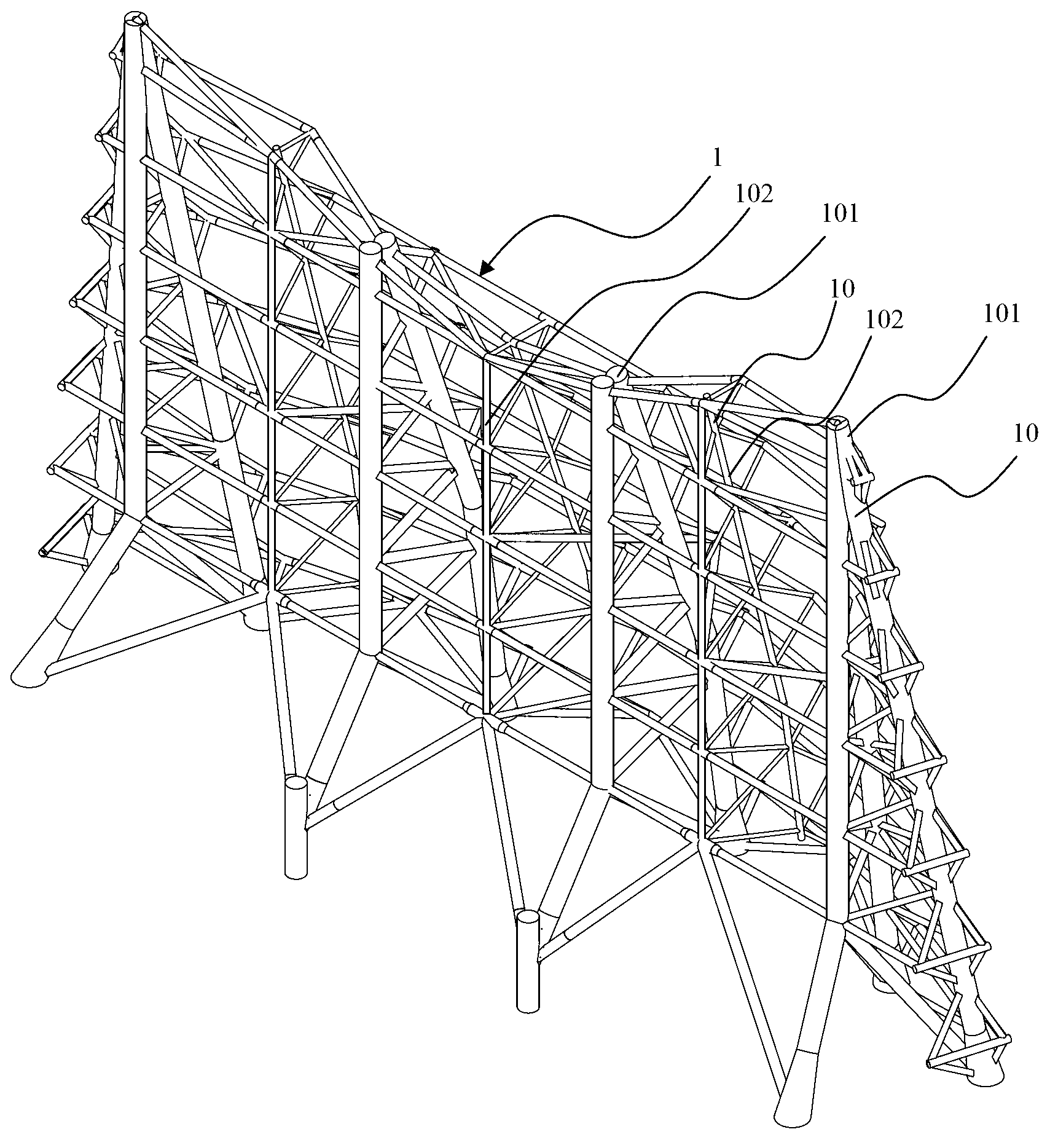

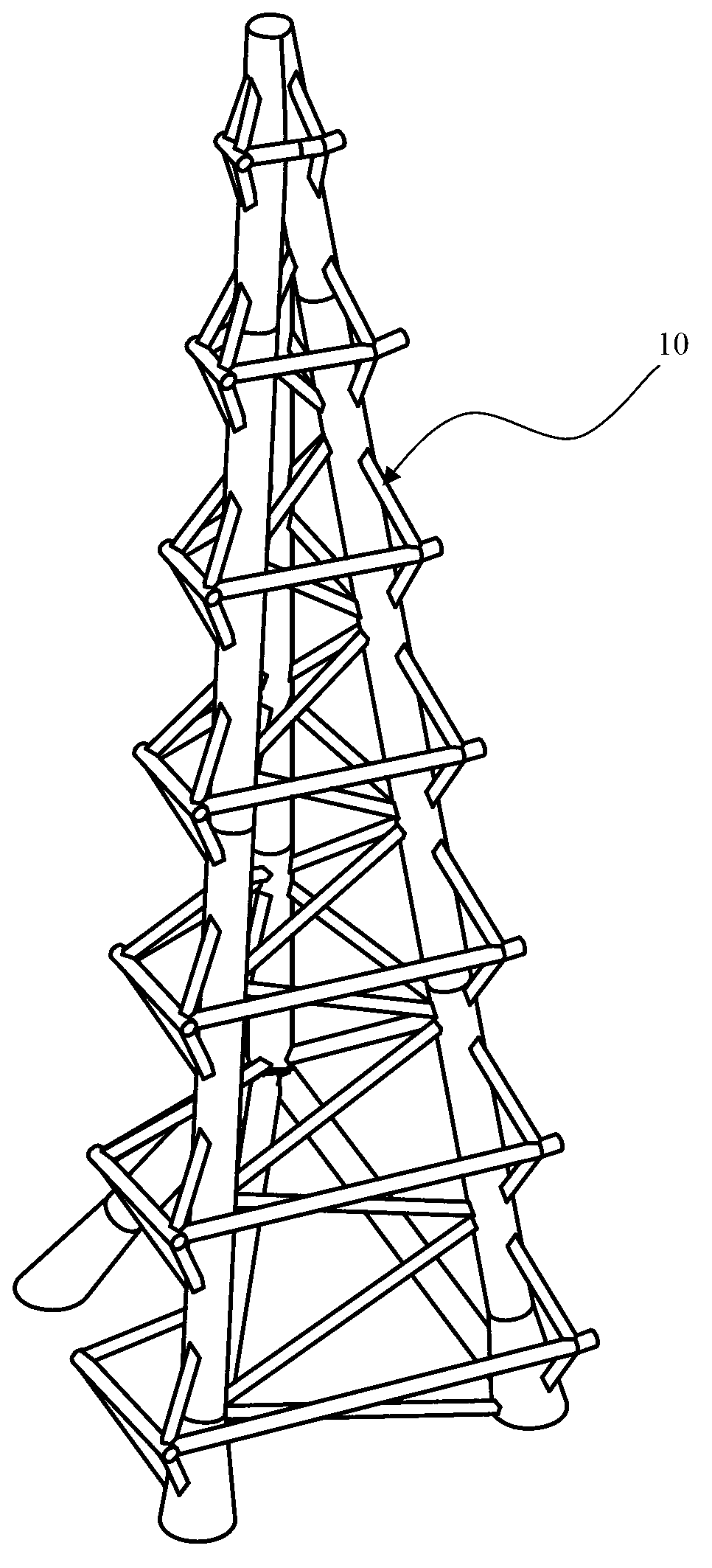

[0053] see figure 1 , a kind of super high-rise special-shaped structure steel structure truss construction method of the present invention, comprises the following steps:

[0054] First, establish a three-dimensional simulation model of the truss;

[0055] Step 1: Using the preset node coordinate list, input it into AutoCAD to establish the point coordinates of the overall model. According to the side view and front view, connect the nodes into a line model;

[0056] Step 2: According to the preset bar section diagram combined with the bar section dimension table, using the line model, each connection line is used as the positioning control axis of the bar, and the preliminary three-dimensional model is generated by using drawing commands such as 3D sweeping, stretching, and lofting;

[0057] Step 3: The three-dimensional model simply generated by using the line model is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com