Construction technology of reelingly stirring to eject anchor tube pile

A construction technology and technology of anchor pipe piles, which are applied in sheet pile walls, infrastructure engineering, buildings, etc., can solve problems such as group anchor effect, deformation of enclosure structure, and reduction of bearing efficiency of anchor group, and achieve high construction cost, The effect of speeding up the construction speed and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

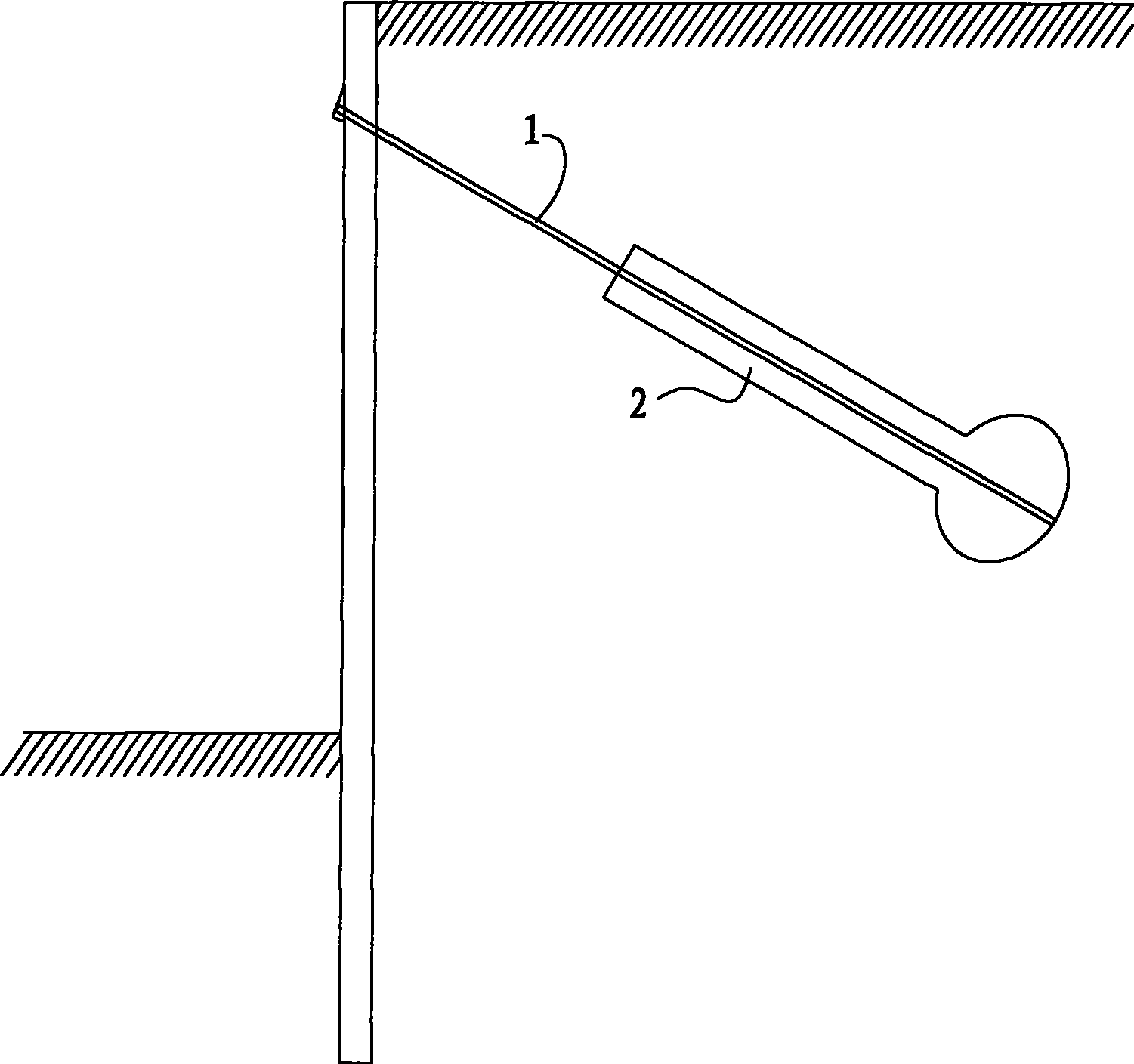

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] The construction technology of this whirling jet anchor pile comprises the following steps:

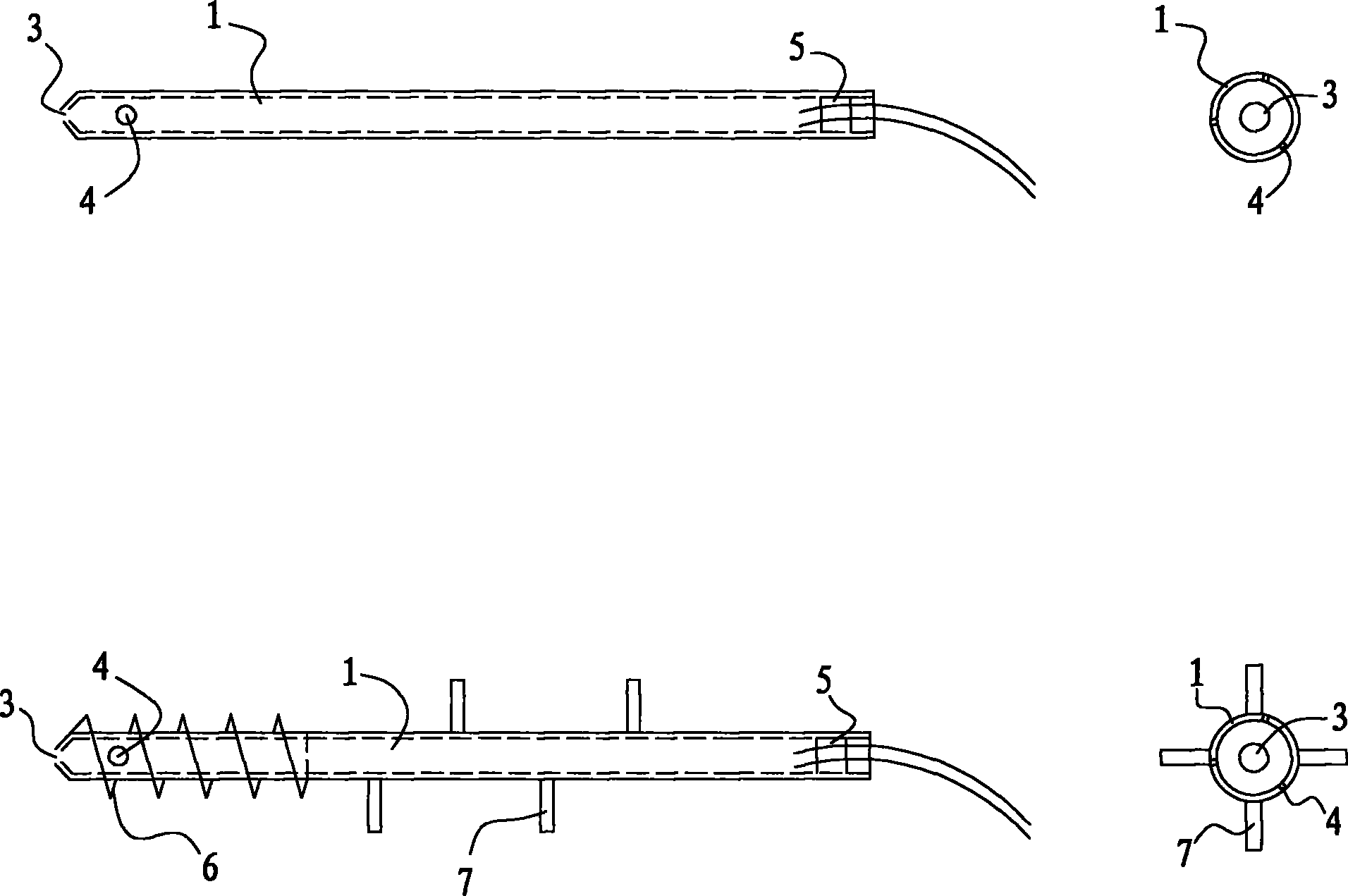

[0028] 1) Positioning, align the hollow anchor tube with the hole position;

[0029] 2) Drilling, use the anchor rod construction equipment to drive the anchor pipe to drill into the soil;

[0030] 3) Grouting, while drilling, grouting equipment is used to spray grout to the soil through the anchor pipe;

[0031] 4) After the pile is formed, the construction equipment is separated from the anchor pipe, and locked and sealed.

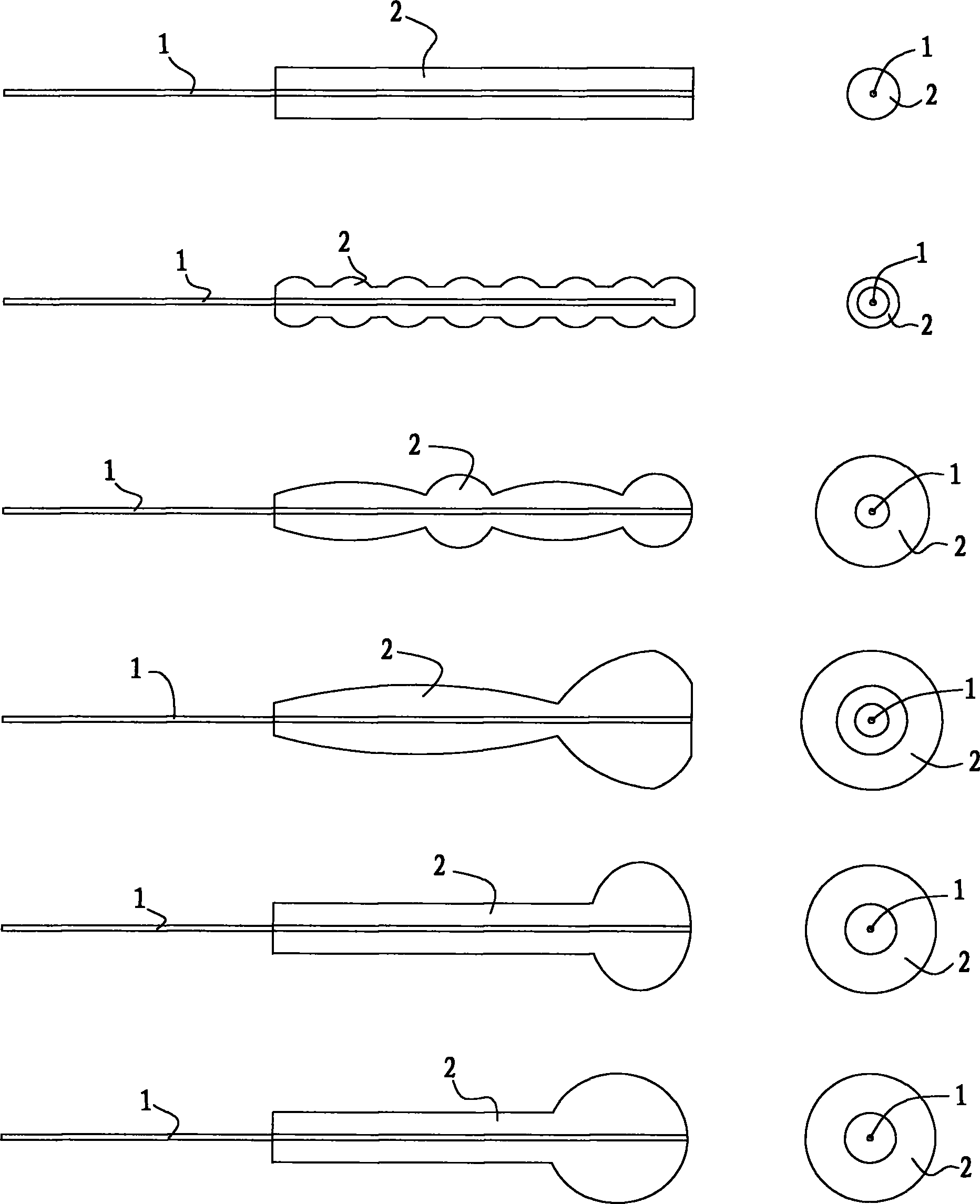

[0032] When drilling, by controlling the drilling speed, the rotating speed of the drilling rig in the construction equipment and the grouting pressure, the diameters of the sections of the swirling jet anchor pile 2 are different. At the large diameter of the anchor pile 2, the drilling speed is 1-70 cm / min, the drilling rig speed is 2-15 rpm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com