Degumming composite, degumming aerosol and preparation method thereof

A composition and aerosol technology, applied in detergent composition, soap detergent composition, surface active non-soap compound and washing composition, etc., can solve potential safety hazards, easy failure, and few types of glue removers And other problems, to achieve the effect of good glue removal, improve work efficiency, and solve the effect of heavy labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

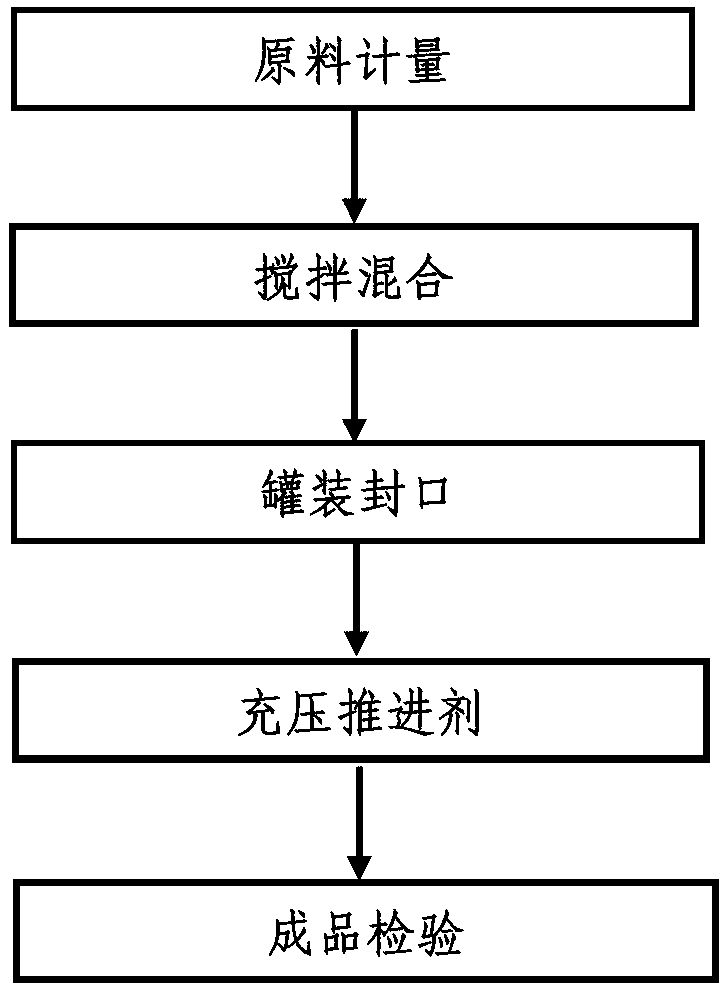

Method used

Image

Examples

Embodiment 1

[0043] Prepare 1000.00g dosage, and the pressure of nitrogen filling is 0.76MPa.

[0044] 1. Accurately weigh 500.00g of D-limonene, Span 60, Span 80, AEO-9, APG (C 8-10 The masses of) are 131.25g, 87.50g, 43.75g, 87.50g, benzyl alcohol 90.00g, and butyl carbitol 60.00g.

[0045] 2. Add the raw materials into a clean container while stirring, and stir for 20 minutes to make the materials completely mixed and uniform to obtain the agent;

[0046] 3. Put the obtained agent into the aerosol tank;

[0047] 4. Sealing and pressurizing propellant;

[0048] 5. Finished product inspection, including whether the outer packaging is deformed, whether the internal pressure complies with GB / T14449-2008, and the airtightness of conventional aerosol products. The qualified product is considered qualified.

Embodiment 2

[0050] Prepare 1000.00g dosage, and the pressure of nitrogen filling is 0.76MPa.

[0051] 1. Accurately measure D-limonene 550.00g, Span 20, Span 80, AEO-9, APG (C 8-10 The masses of) are: 100.00g, 100.00g, 40.00g, 60.00g, propylene glycol methyl ether 83.33g, and benzyl alcohol 66.67g.

[0052] 2. Add the raw materials into a clean container while stirring, and stir for 20 minutes to make the materials completely mixed and uniform to obtain the agent;

[0053] 3. Put the obtained agent into the aerosol tank;

[0054] 4. Sealing and pressurizing propellant;

[0055] 5. Finished product inspection, qualified product is deemed qualified.

Embodiment 3

[0057] Prepare 1000.00g dosage, and the pressure of nitrogen filling is 0.85MPa.

[0058] 1. Accurately measure D-limonene 600.00g, Span 60, Span 40, AEO-9, APG (C 8-10 The masses of) are: 120.00g, 80.00g, 40.00g, 40.00g, carbitol 60.00g, and butyl carbitol 60.00g.

[0059] The production process is as follows:

[0060] 1. Accurately measure the above-mentioned raw materials according to the above-mentioned amount, add the raw materials into a clean container while stirring, and stir for 20 minutes to make the materials completely mixed and uniform to obtain the agent;

[0061] 2. Put the obtained agent into the aerosol tank;

[0062] 3. Sealing and pressurizing propellant;

[0063] 4. Finished product inspection, qualified product is deemed qualified.

[0064] The airworthiness verification of the products in Example 1-3 is carried out by the Test Center of the Civil Aviation Administration of China. The certification basis is SAE AMS1550B. The main test part is the aircraft material com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com