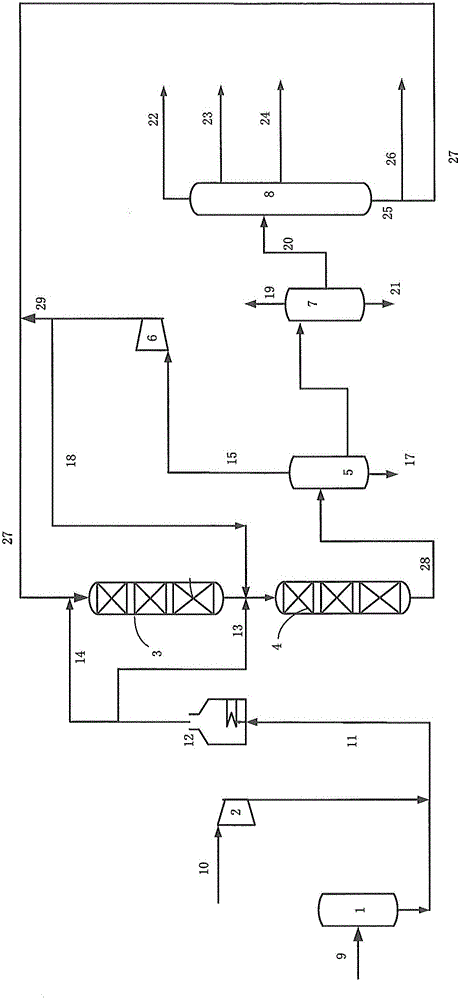

Hydrogenation method for production of high quality middle distillate oil

A technology for middle distillate oil and distillate, which is applied in the field of hydrocracking, can solve the problems of low yield of middle distillate oil, etc., and achieve the effects of improving yield, improving selectivity and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] When the reaction pressure is 14.5MPa, the reaction temperature of hydrogenation reactor I is 380°C, the reaction temperature of hydrogenation reactor II is 370°C, and the volume space velocity of hydrogenation reactor I (for fresh raw materials) is 1.8h -1 , Hydrogenation Reactor II Volume Space Velocity (total feed to Hydrogenation Reactor II) is 1.3h -1 Under the reaction conditions, with the hydrocracking method that the present invention provides, adopt raw material A to carry out test. The ratio of fresh feedstock oil entering hydrogenation reactor I and hydrogenation reactor II is 4:1, and all tail oil fractions are recycled back to hydrogenation reactor II. H in the hydrogenation reactor II reaction atmosphere 2 S partial pressure is 0.03MPa, NH 3 The partial pressure is 0.006MPa. The test results are shown in Table 2. Based on 100% fresh raw materials, the yields of jet fuel and diesel are 42.33% and 39.12%, respectively, the total yield of middle distillate...

Embodiment 2

[0038] When the reaction pressure is 14.5MPa, the reaction temperature of hydrogenation reactor I is 380°C, the reaction temperature of hydrogenation reactor II is 380°C, and the volume space velocity of hydrogenation reactor I (for fresh raw materials) is 1.8h -1 , Hydrogenation Reactor II Volume Space Velocity (total feed to Hydrogenation Reactor II) is 1.3h -1 Under the reaction conditions, with the hydrocracking method that the present invention provides, adopt raw material A to carry out test. The ratio of fresh raw oil entering hydrogenation reactor I and hydrogenation reactor II is 2:1, and the tail oil fraction is all recycled back to hydrogenation reactor II. H in the hydrogenation reactor II reaction atmosphere 2 S partial pressure is 0.05MPa, NH 3 The partial pressure is 0.01MPa. The test results are shown in Table 3. Based on 100% fresh raw materials, the yields of jet fuel and diesel are 41.98% and 38.67%, respectively, the total yield of middle distillates is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com