Seedling production device

A technology of production device and clamping device, applied in horticulture, application, botany equipment and methods, etc., can solve problems such as affecting cutting quality and docking failure, and achieve the effect of fast docking and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

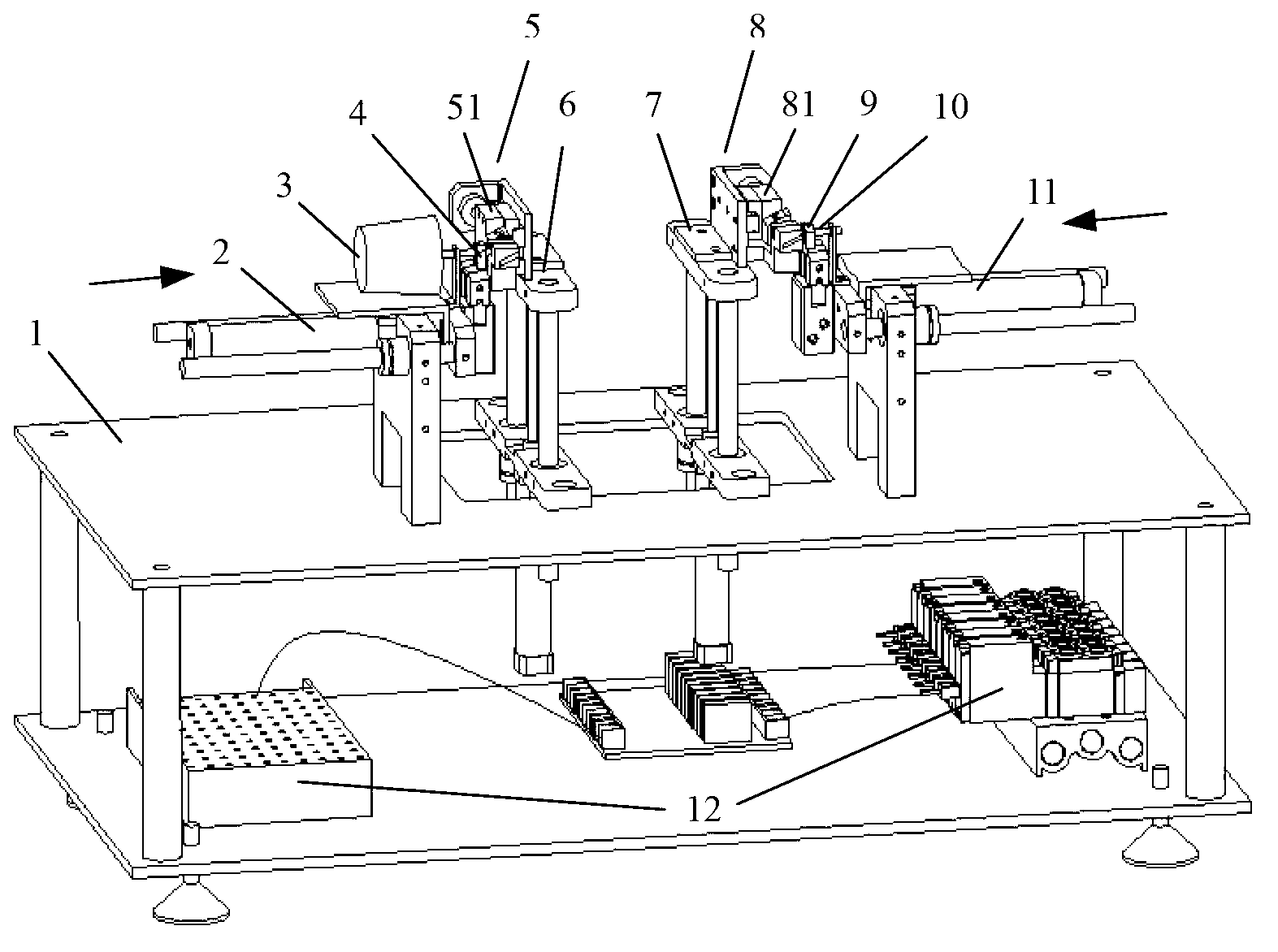

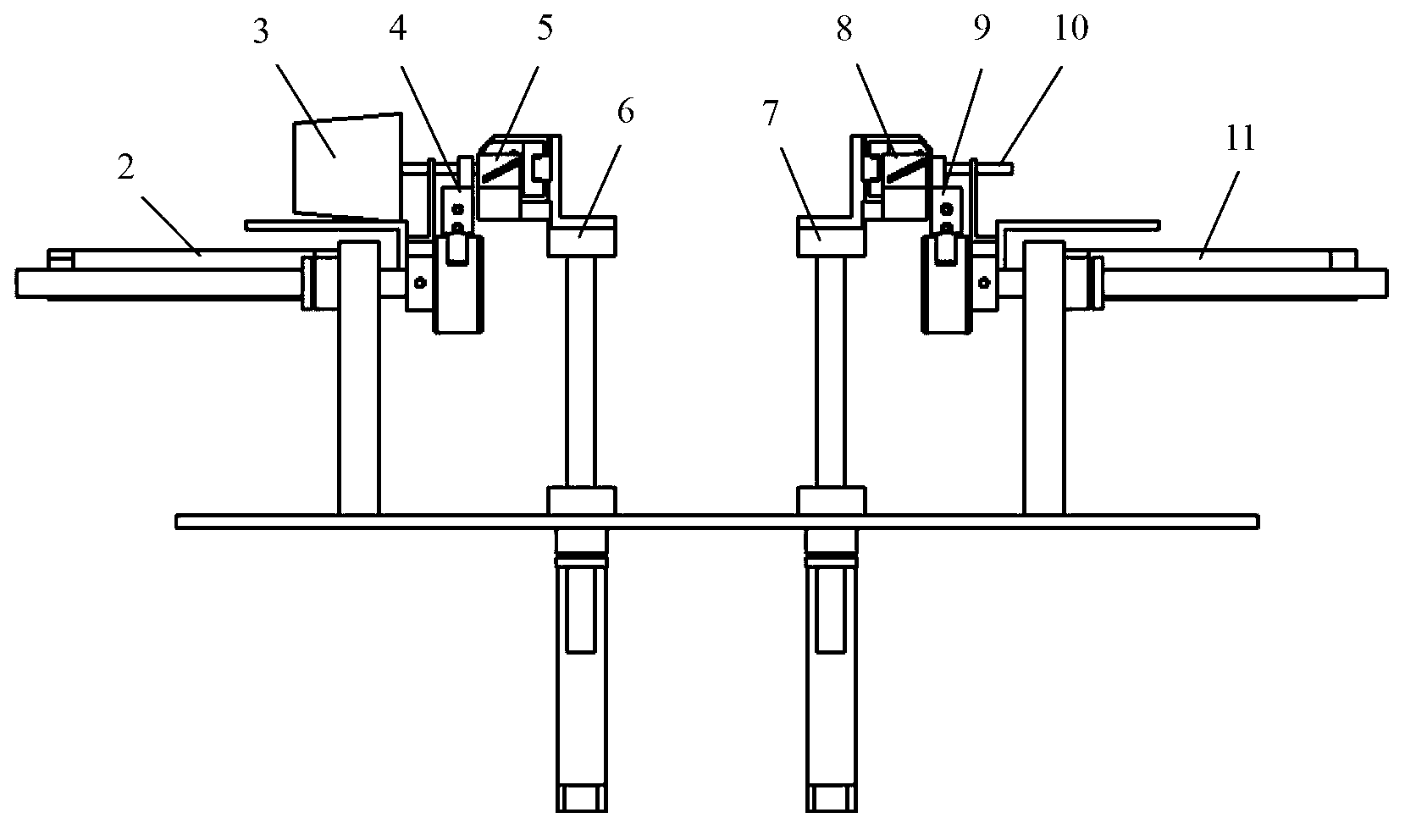

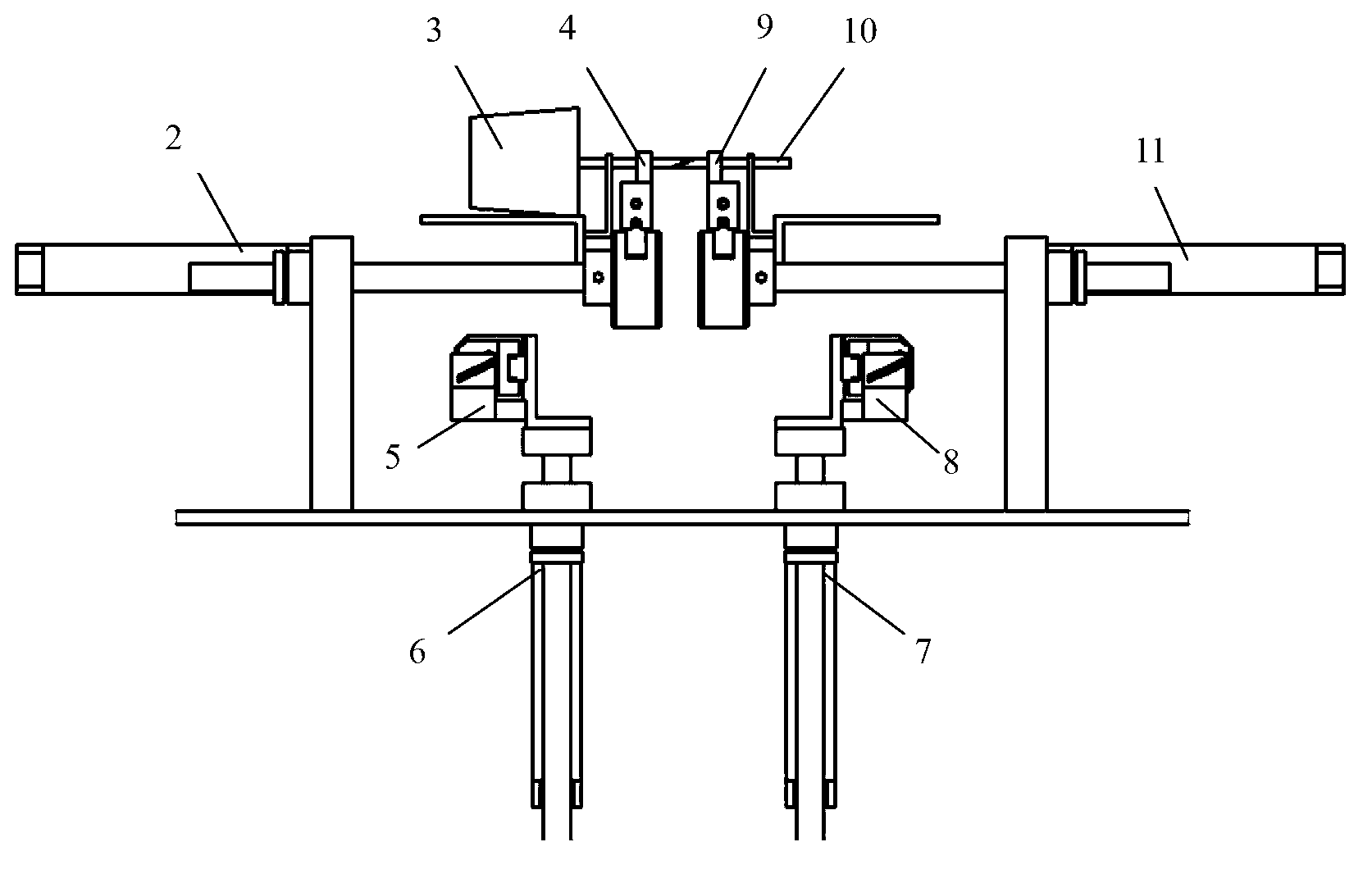

[0051] figure 1 Shown is a schematic structural view of the seedling production device in Embodiment 1 of the present invention. Such as figure 1 As shown, the seedling production device in the present embodiment includes an operating platform 1 and a first pushing mechanism 2 fixed on the operating platform 1, a second pushing mechanism 11, a first cutting mechanism 5 and a second cutting mechanism 8, and also includes respectively The first clamping device 4 for horizontally clamping the rootstock 3 and the second clamping device 9 for horizontally clamping the scion 10 are fixed on the first pushing mechanism 11 and the second pushing mechanism 5 . Wherein, the first pushing mechanism 11 and the second pushing mechanism 5 are relatively arranged, that is, the pushing directions of the first pushing mechanism 11 and the second pushing mechanism 5 face each other, as figure 1 As shown in the direction of the middle arrow, it is used to horizontally push the first clamping d...

Embodiment 2

[0065] In order to reduce the cost and versatility of the equipment and facilitate the control of each device, it is preferred that the first lifting mechanism 6 and the second lifting mechanism 7 have the same structure in this embodiment.

[0066] Figure 4 Shown is a schematic structural view of the cutting device in the second embodiment of the invention. There are many ways in which the rootstock 3 and the scion 10 can be cut in a push-cut manner. In this embodiment, the preferred first cutting device 51 includes a fixed seat 27 fixed on the first elevating mechanism 6, such as Figure 4 Shown, fixed seat 27 is installed with cutting cylinder 22, slide rail 25 and seedling cutting seat 28 successively from left to right, can carry out fixed installation by bolt, wherein, slide block 24 is slidably provided with on slide rail 25, and slide On the block 24, a knife seat 30 is fixedly installed, and the knife seat 30 is connected with the piston rod of the cutting cylinder ...

Embodiment 3

[0081] It has been explained above that each device in the equipment can be controlled individually or centrally. In this embodiment, centralized control is preferred, which can reduce the impact of human factors on the accuracy and speed of grafting.

[0082] Figure 8 Shown is a block diagram of the electrical control system in Embodiment 3 of the present invention. Such as Figure 8 As shown, the electrical control system 12 in this embodiment includes a clamping control device 100, a cutting control device 101, a lifting control device 102 and a pushing control device 103, wherein the clamping control device 100 is compatible with the first clamping device 4 and the second clamping device 4. The clamping device 9 is electrically connected, and is used to control the first clamping device 4 and the second clamping device 9 to clamp the stock and the scion respectively; the cutting control device 101 is electrically connected with the first cutting mechanism 5 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com