Method and device for measuring minute amplitude vibration of laser focused measuring head

A vibration device and focusing technology, which is applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, using wave/particle radiation, etc., can solve problems such as the inability to measure vibrations below the micron level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

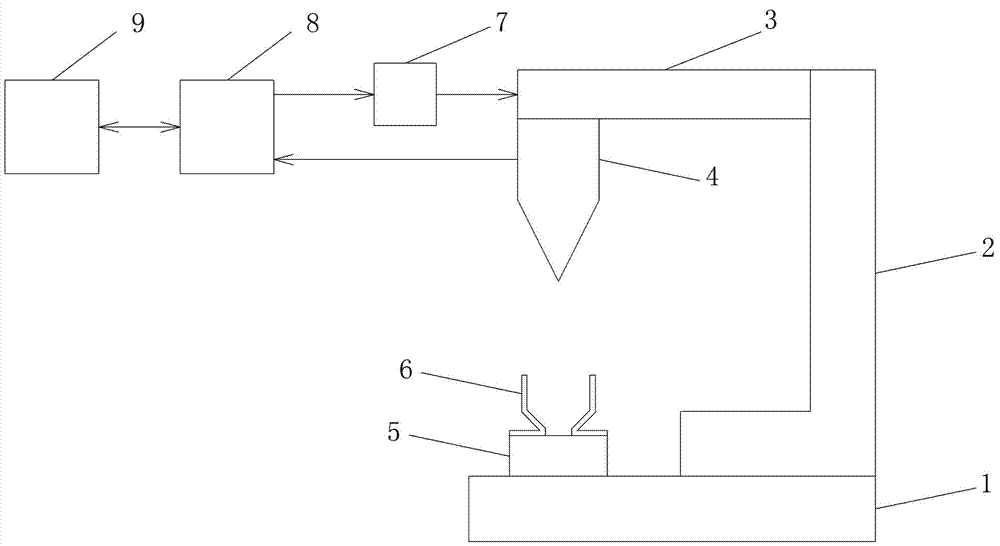

[0009] According to attached figure 1 , the composition of the device for measuring micro-amplitude vibration with a laser-focused probe of the present invention includes a base 1, a bracket 2, an electric lifting platform 3 (stroke L), a laser-focusing probe 4, a horizontal moving platform 5, a fixture 6, and an electric lifting platform A controller 7, a data acquisition card 8, and a data processor 9. One side of the upper plane of the base 1 is fixed with an L-shaped support 2, and an electric lifting platform in the form of a cantilever beam is arranged on the top of the support 2, and the electric lifting platform moves up and down along the support 1, and a laser focusing probe 4 is set on the lower side of the cantilever end of the electric lifting platform. A horizontal moving platform 5 and a fixture 6 for clamping the vibration device to be tested are arranged directly under the laser focusing probe 4. The fixture 6 is on the horizontal moving platform 5, and the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com