LED (light-emitting diode) light distribution system adopting free-form surface lens and reflector as well as design method of LED light distribution system

A technology of curved lens and system design, applied in the field of LED light distribution system, can solve problems such as inability to maintain, the direction of light cannot be adjusted, and high optical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

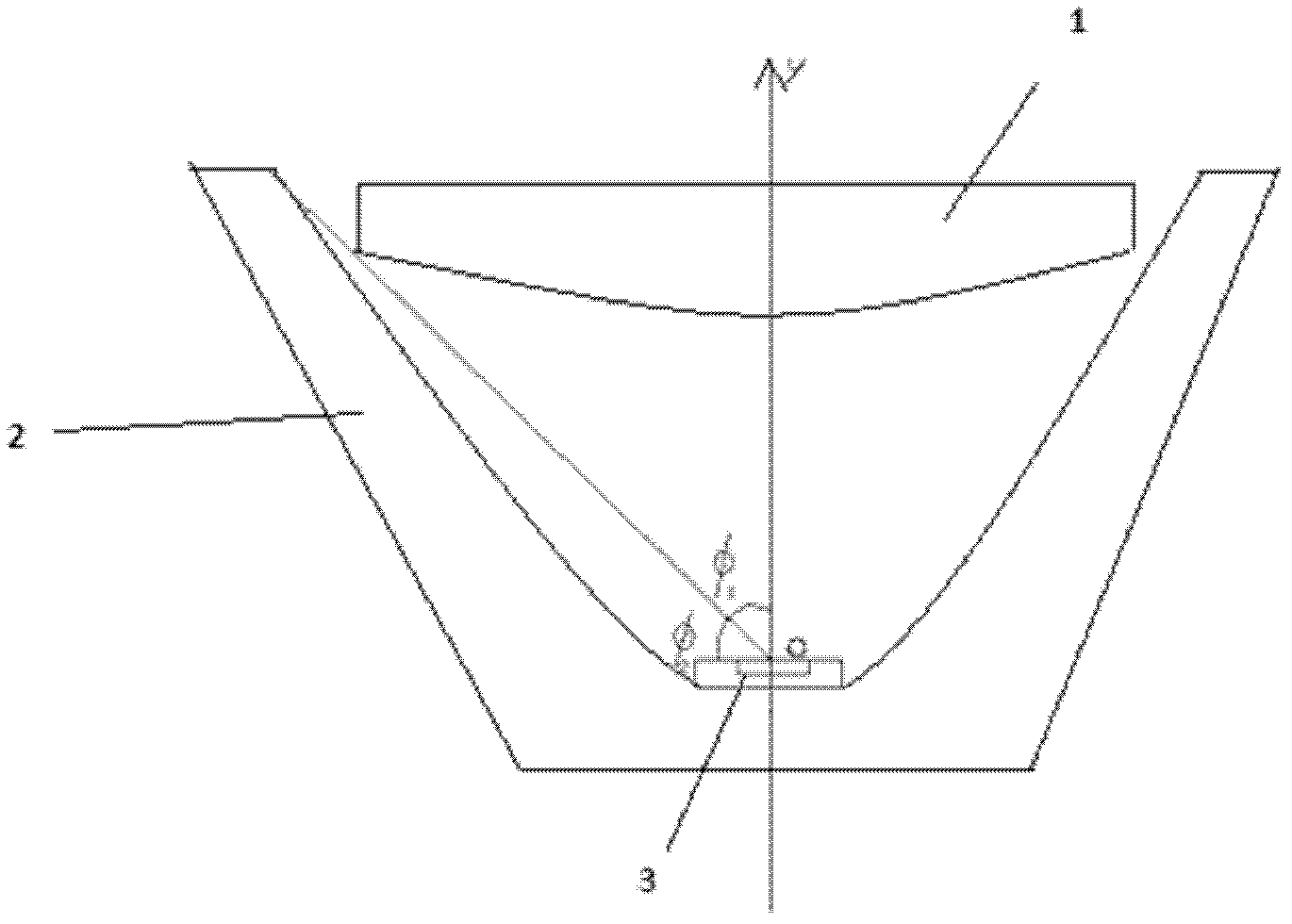

[0098] Embodiment 1: the optical system of lens and reflector is taken as attached figure 2 In the form shown, part of the light from the light source is refracted to the target surface through the lens, and the other part is reflected to the target surface through the reflector without being refracted by the lens. The inner surface of the lens adopts a free-form surface, and the outer surface adopts a plane. The light source adopts Lambertian LED, namely I is the central light intensity. The target surface is 10 meters away from the light source, and it is required to form a giant uniform spot with a length of 30 meters and a width of 10 meters, and its center is on the y-axis.

[0099] First, divide the light emitted by the LED, take φ0=60 degrees, then the light emitted by the LED in the range of 0°≤φ0 ≤φ≤90° adopt reflector design.

[0100] Place the LED at the origin of the coordinate system so that its central axis coincides with the y-axis. A known And the illumi...

Embodiment 2

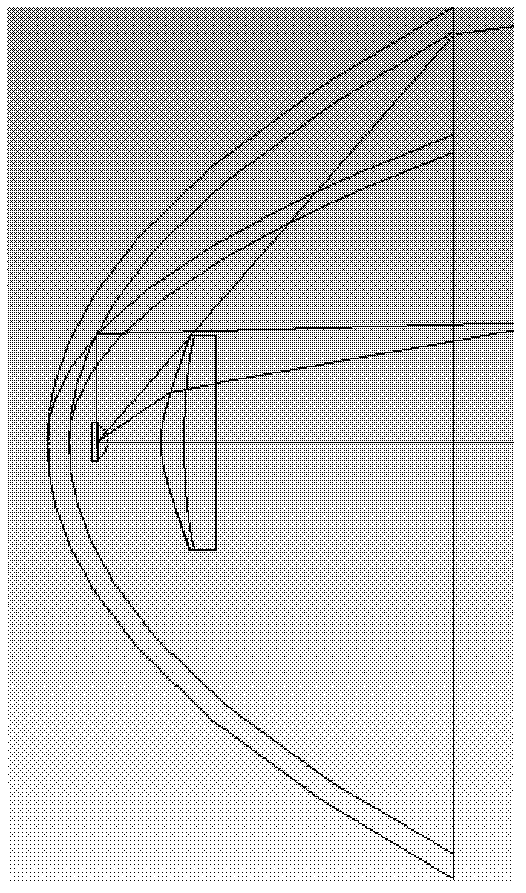

[0122] Embodiment 2: the optical system of lens and reflector is taken as attached Figure 4 In the form shown, part of the light from the light source is refracted to the target surface through the lens, and the other part is reflected to the lens part through the reflector, and then refracted to the target surface. The inner surface of the lens adopts a free-form surface, and the outer surface adopts a plane. The calculation of this form of optical system is relatively complicated for reflectors, because the light is reflected first, then refracted, and finally incident on the target surface, which needs to be combined with the reflectance formula and the refractive index formula. The mapping relationship for light is the same as in Embodiment 1, but the obtained expression needs to be substituted into the reflectance formula and the refractive index formula. After listing the equations, the points on the surface are obtained through computer iterative solution, and then th...

Embodiment 3

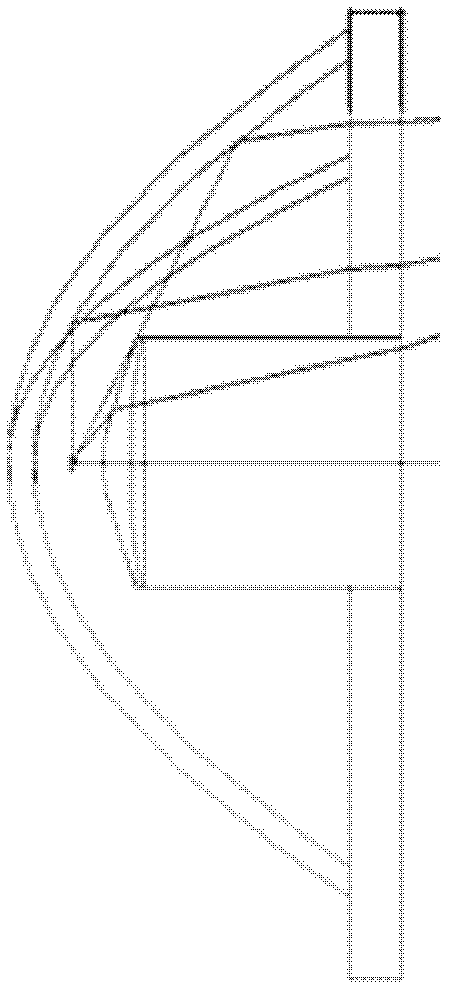

[0123] Embodiment 3: the optical system of lens and reflector is taken as attached Figure 5 The form shown adopts the integrated design of lens and reflector. Part of the light from the light source is refracted to the target surface through the lens, and the other part is totally reflected to the target surface through the inner surface of the reflector. The inner surface of the lens adopts a free-form surface, and the outer surface adopts a plane. This form of reflector part needs to consider that the light incident on the reflective surface needs to be refracted once to enter the medium. refraction formula [ 1 + n 2 - 2 n ( Out → · In → ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com