Sealing switch of fuel system

A fuel system and switch technology, which is applied in the direction of sliding valves, engine components, mechanical equipment, etc., can solve the problems that the elastic sealing ring and the movable plate can not be guaranteed to fit completely, and achieve good economy, practicability and high reliability , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

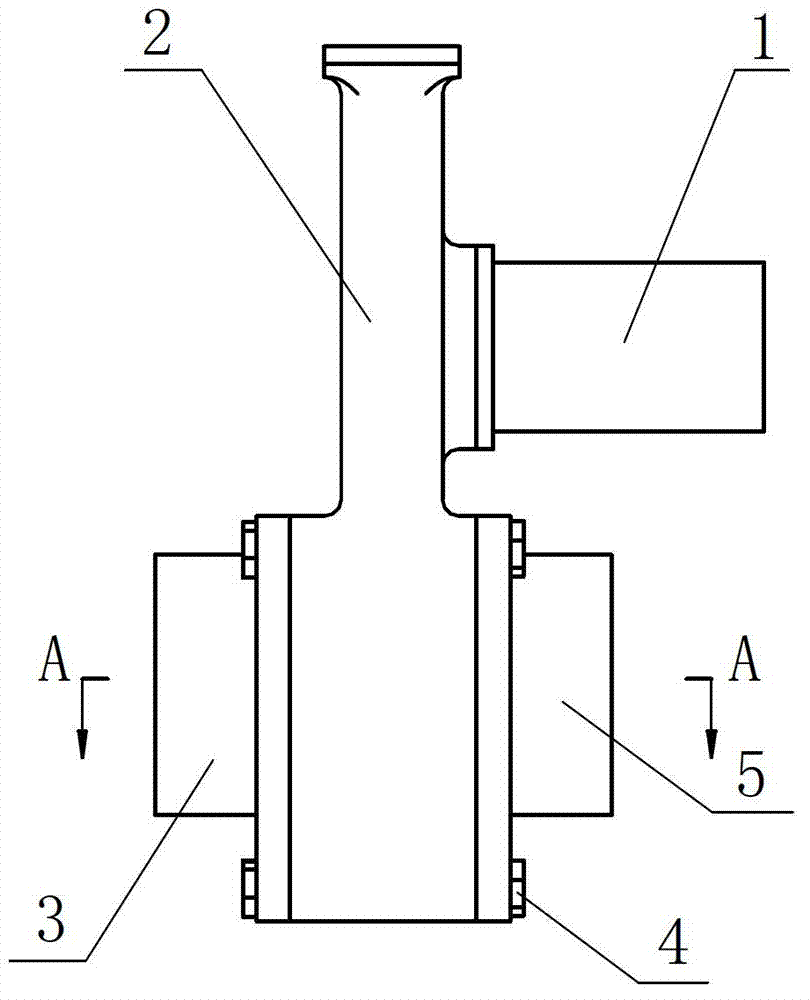

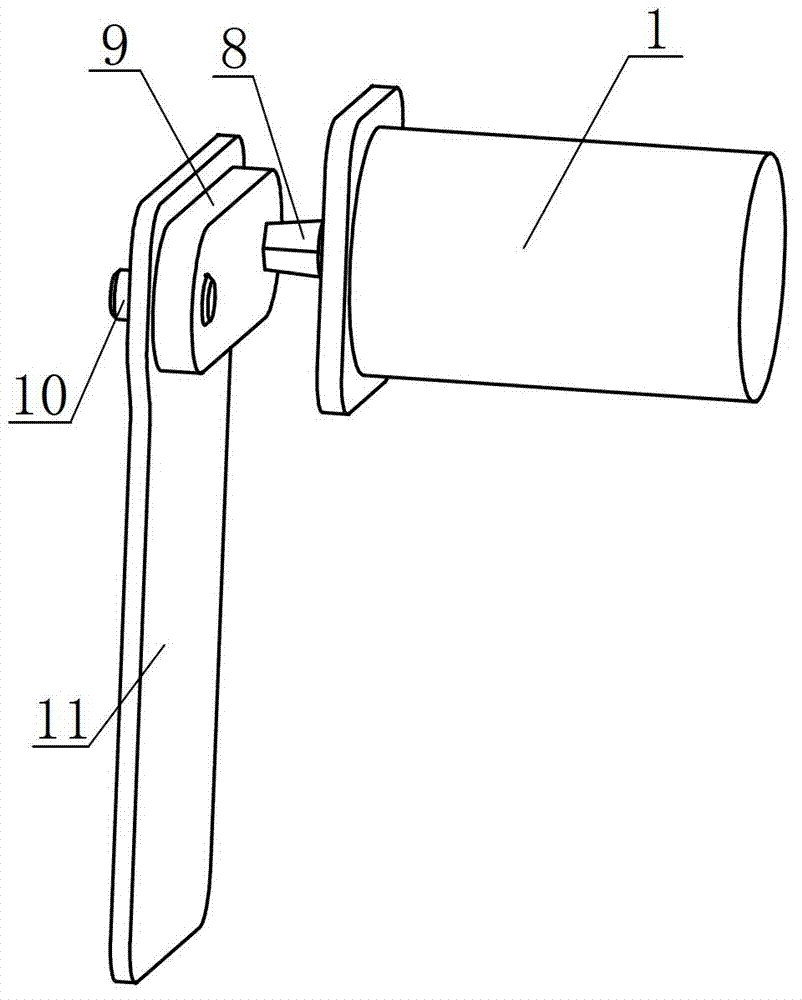

[0022] This embodiment is a fuel system seal switch for a certain type of engine. like figure 1 As shown, this embodiment is located between the fuel pipelines, and the motor 1 drives the movable plate 11 in the switch box 2 to move up and down to realize the switch of the pipelines.

[0023] This embodiment includes a motor 1, a switch box 2, a linkage mechanism and a sealing assembly. It is obtained by improving the existing technology.

[0024] like figure 2 As shown, the switch box 2 is composed of a casting box body 7 and a box cover 6. The linkage mechanism and the sealing ring assembly are installed in the box body 7, and the linkage mechanism is located on the upper part of the switch box 2, and the sealing ring assembly is located on the switch box 2. the lower part. The upper part of the switch box has a through hole for the motor shaft, and the lower part of the switch box has a through oil delivery hole. The box body 7 and the box cover 6 are connected with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com