Fast connecting module having active positioning mechanism

A technology of movable positioning and positioning components, which is applied in the direction of connecting components, mechanical equipment, friction clamping detachable fasteners, etc., can solve the problems of waste time, cumbersome assembly procedures, etc., and achieve convenient operation, fast assembly, and operation The effect of firm fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail by means of the following specific embodiments and accompanying drawings, as follows:

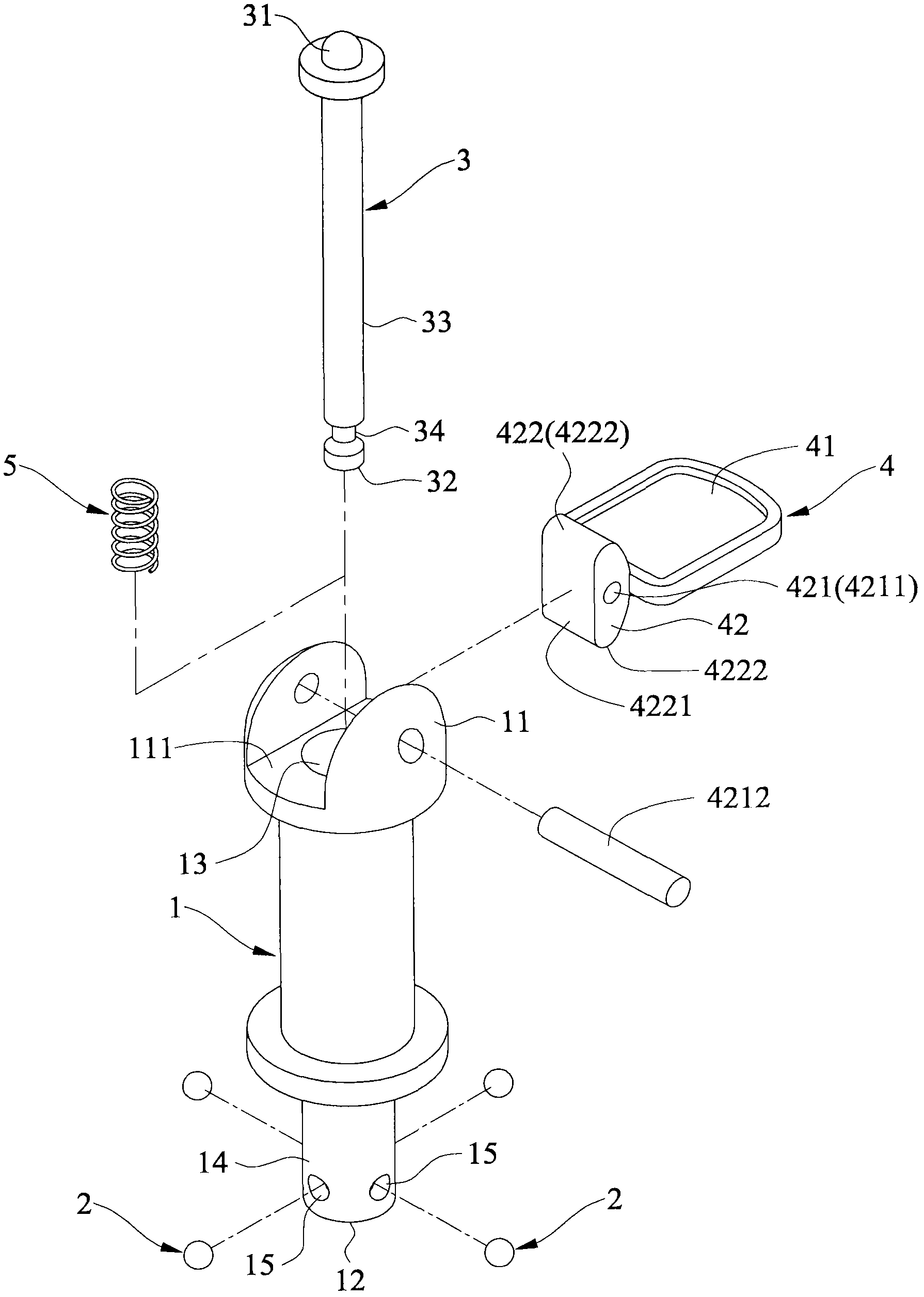

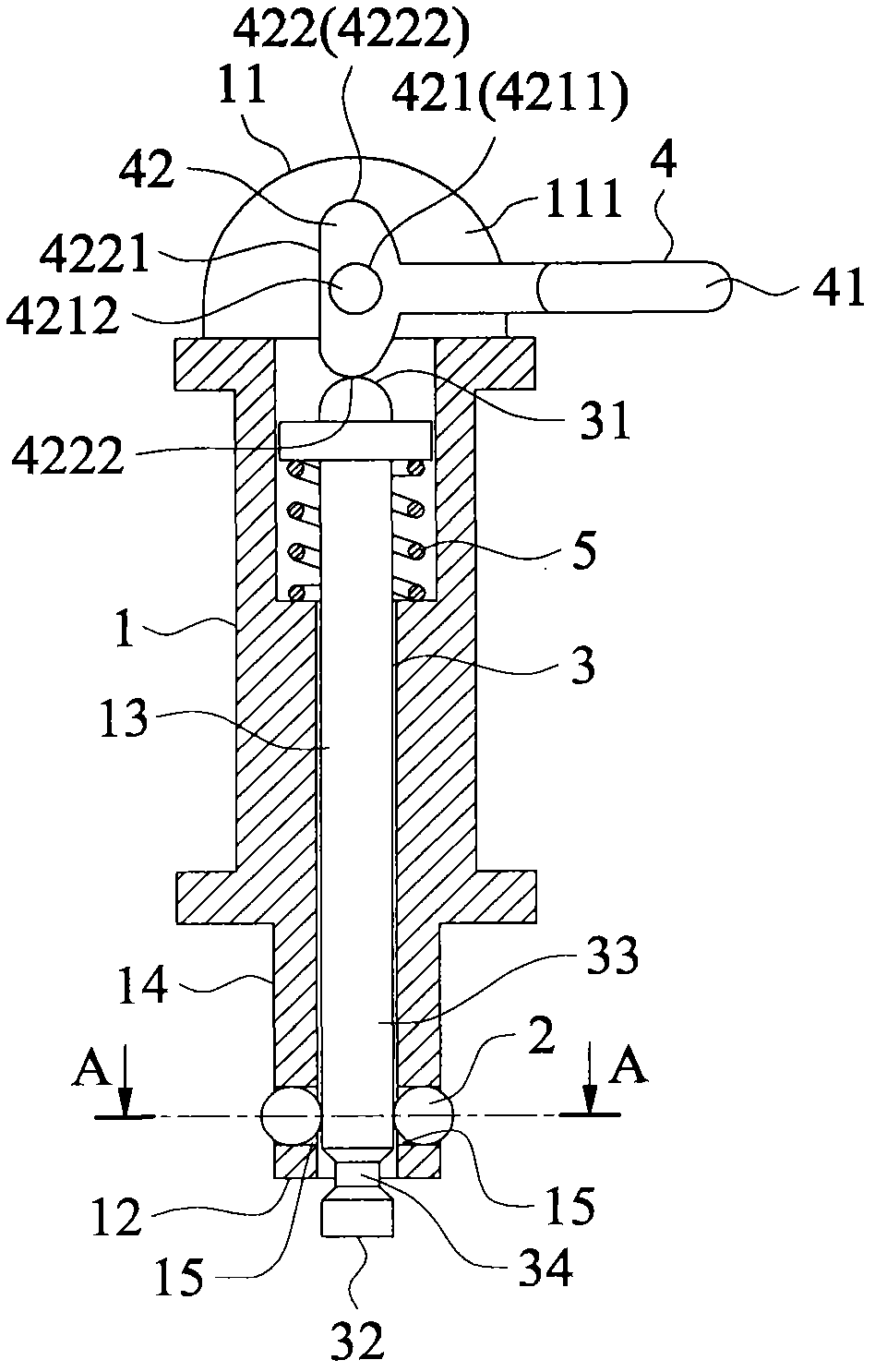

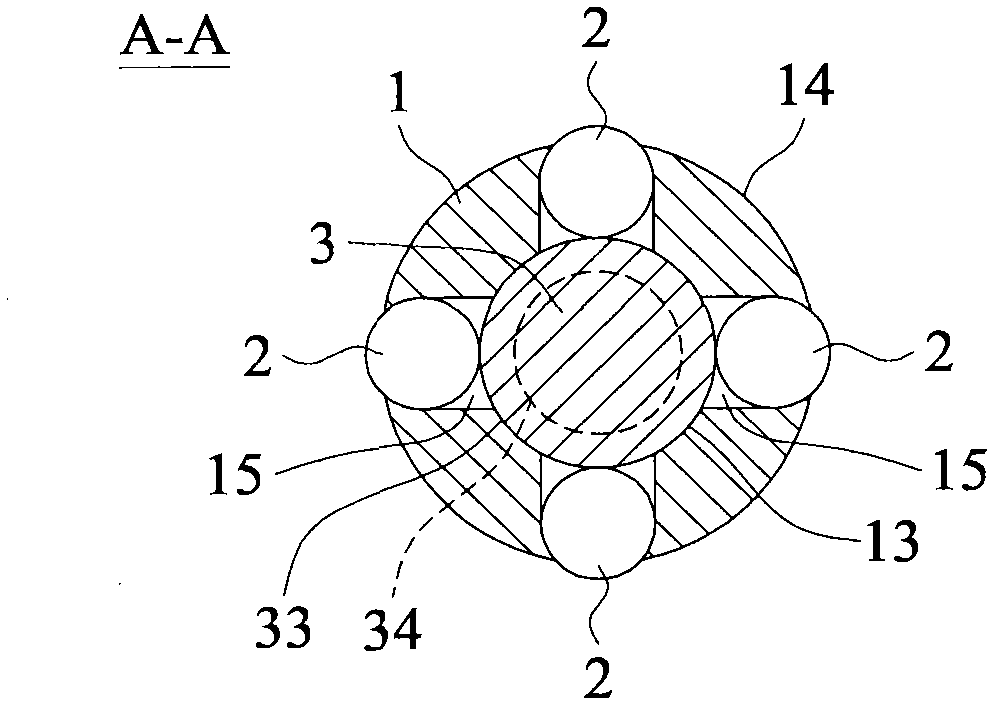

[0046] like figure 1 , figure 2 , image 3 and Figure 4As shown, the rapid assembly module with a movable positioning mechanism of the present invention is a rapid assembly module used to directly or indirectly assemble a first object 10 and to buckle a second object 20, which is relatively A preferred embodiment includes a buckle assembly 1, one or more positioning assemblies 2, a central control assembly 3 and a pull assembly 4, wherein:

[0047] The fastening assembly 1 is a circular or other shaped structure, which includes a first end 11, a second end 12 opposite to the first end 11, and a first end connecting the first end 11 and the second end 12. Through hole 13, an outer surface 14 located between the first end 11 and the second end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com