On-line rocker winding film packaging machine

A packaging machine and laminating technology, which is applied in the field of online rocker arm wrapping laminating packaging machine, can solve the problems of occupying a large space and human resources, troubled by the development of the wrapping packaging industry, and unable to cover the top film, etc., and achieves simple and convenient operation. Beautiful appearance and good packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

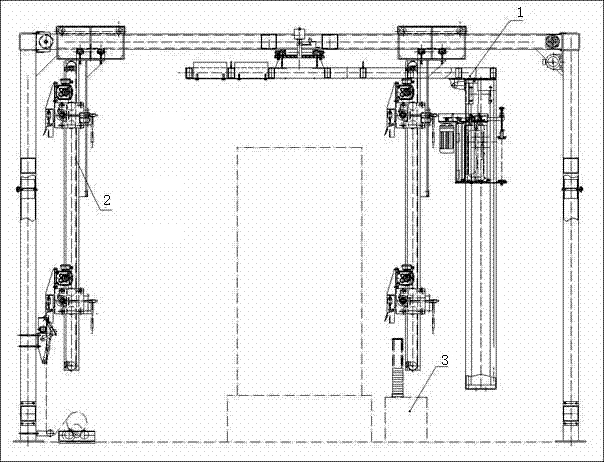

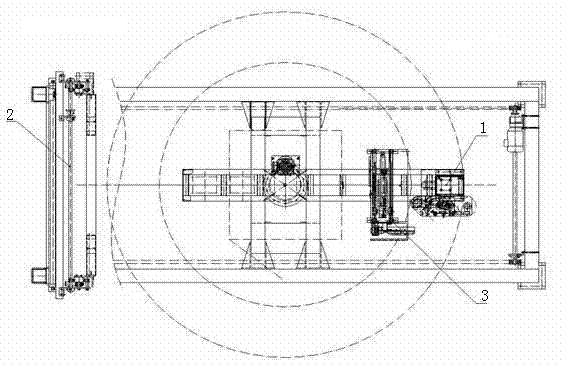

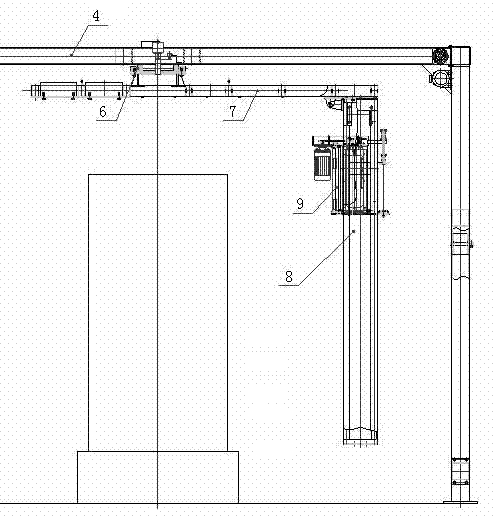

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. This embodiment is an online rocker arm wrapping film packaging machine, which is characterized in that it includes a rocker arm winding host 1, a top film mechanism 2 and an automatic film breaking mechanism 3; the rocker arm online host 1 includes a gantry 4. Rocker arm reducer 5, slewing bearing 6, rocker arm 7, lifting frame parts 8, mold frame 9; the top-covering film mechanism 2 includes a film roll placement frame 13, a film roll guide part 14, and a pinch-off film mechanism 15. A vertical film pulling mechanism 16 and a horizontal movement mechanism 17;

[0023] The rocker arm winding host 1 is composed of gantry frame 4, rocker arm reducer 5, slewing bearing 6, rocker arm 7, lifting frame component 8, and mold frame 9. The rocker arm 7 is connected to the gantry frame 4 Connected, the rocker arm reducer 5 drives the rocker arm 7 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com