A rear body rectification structure of a twin-engine aircraft

A technology for aircraft and engine hoods, which is applied in the field of rear body rectification structure of twin-engine aircraft, and can solve problems such as aircraft vibration and airflow separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

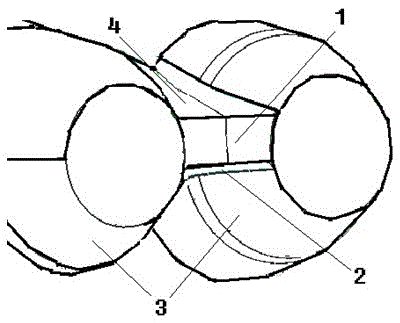

[0013] Embodiments of the present invention are as follows: figure 1 Shown, a kind of rear body rectification structure of twin-engine aircraft comprises: rectification rear end surface 1, rectification lower surface 2 and rectification upper surface 4, and forms the rectification structure of shape closure with rear body engine cover 3; Rectification lower surface 2 and rectification The upper surface 4 is located in the middle of the two engine covers 3 of the rear body of the aircraft, the rectifying rear end surface 1 is connected up and down with the rectifying upper surface 4 and the rectifying lower surface 2, and the two engine covers 3 are connected left and right.

[0014] The rectifying upper surface 4 transitions smoothly along the airflow direction along the upper profile of the rear body, ensuring that the contraction angle of the upper surface is less than 9°; the rectifying lower surface 2 transitions smoothly along the airflow direction along the lower profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com