Moped provided with sensor with unevenly distributed positions of magnetic blocks on flywheel

A power-assisted bicycle, evenly distributed technology, is applied in the direction of using electric/magnetic devices to transmit sensing components, vehicle components, rider drive, etc., which can solve the inconsistency between power-assisted output and power-assisted demand, the inability of power-assisted bicycles to assist, and the difference in sensing parameters. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

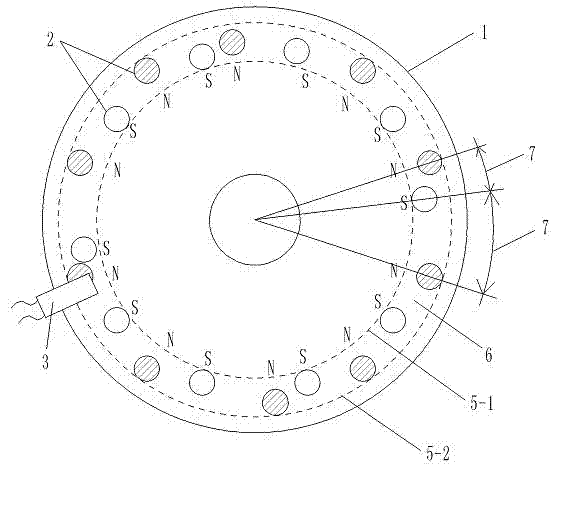

[0118] Embodiment 1. A power-assisted bicycle with a magnetic block position uneven distribution sensor on the flywheel

[0119] Such as figure 1 , 3 , 4, 6,

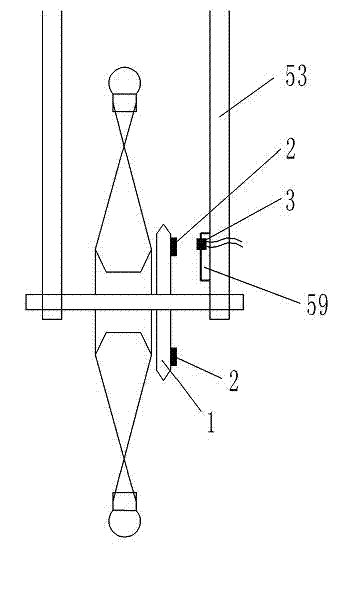

[0120] 1. The components and structure of the electric bicycle related to the installation of the sensor: including the electric bicycle and the sensor, the rear wheel of the electric bicycle has a flywheel 1, the electric bicycle has a frame 53, the battery 55 on the electric bicycle is connected to the motor controller 29, and the motor controller 29 connect the motor 30 on the wheel;

[0121] 2. The structure of the sensor and the connection relationship of the components are as follows:

[0122] The sensor includes a sensing element connected in sequence, a boost model processor 21, a digital-to-analog converter 27 and an operational amplifier 28;

[0123] [1] The sensing element is an element that converts the rotational motion of the flywheel 1 into a rectangular wave signal output;

[0124] The sensing elem...

Embodiment 2

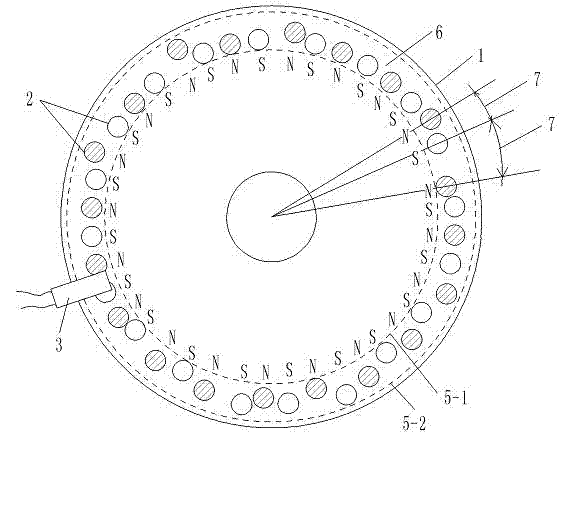

[0142] Embodiment 2. A power-assisted bicycle with sensors for uneven distribution of magnetic block positions on a high-density flywheel

[0143] Such as figure 2 , 3, 4, 6, 40 permanent magnet blocks 2 with a diameter of 0.6 cm are arranged on one surface of a flywheel 1 with a diameter of 10.0 cm. The magnetic flux of the permanent magnet block 2 is 146---279 (B·H)max / KJ·m -3 A certain value, Hall 3 keeps a distance of 0.2 cm from each permanent magnet block 2 in the rotating state, so that when each rotating permanent magnet block 2 passes through Hall 3, Hall 3 can generate a corresponding Rectangular wave signal output. Other structures are the same as in Embodiment 1.

Embodiment 3

[0144] Embodiment 3, a power-assisted bicycle with a magnetic block position uneven distribution sensor on the flywheel with a specific circuit

[0145] Such as figure 1 , 3 , 5, 6, as in embodiment 1, the sensor includes a sensing element connected in sequence, a booster model processor 21, a digital-to-analog converter 27 and an operational amplifier 28;

[0146] [1] The Hall 3 in the sensing element is UGN3075; the structure of other elements and elements in the sensing element is the same as that in Embodiment 1;

[0147] [2] The auxiliary model processor 21 selects the single-chip microcomputer 31 to complete all functions, and the single-chip microcomputer 31 selects AT89S52. That is, the AT89S52 single-chip microcomputer 31 completes all functions of the analog-to-digital conversion and the wave width identifier 22 , the power-assisted starting point selector 23 , the magnet speed calculator 24 , the power-assisted model memory 25 and the power-assisted model calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com