Preparation method of rubber material for preparing high-/low-temperature resistant automobile pipeline rubber products

A technology for rubber materials and automobile pipelines, which is applied in the field of rubber material preparation, can solve the problems of high temperature resistance, low temperature resistance, low tensile strength changes, changes in elongation at break, cold flexural resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the rubber material for preparing high and low temperature resistant automobile pipeline rubber products of the present invention comprises the following steps:

[0028] (1) Cool the internal mixer with water, put rubber raw materials, reinforcing fillers, plasticizers, active agents, anti-aging agents and lubricants into the internal mixer for internal mixing, and control the temperature of the rubber below 130°C. Glue removal, sheet release and cooling on an open rubber mixer to obtain masterbatch;

[0029] (2) Put the masterbatch into the internal mixer, add vulcanizing agent evenly for mixing, control the temperature of the glue below 90°C to discharge the glue, and make strips on the open rubber mixer, cool and leave it to mature, and obtain the raw materials for the manufacture of automobiles. High and low temperature resistant rubber materials used in products such as engine and transmission oil cooling pipes.

[0030] In the present in...

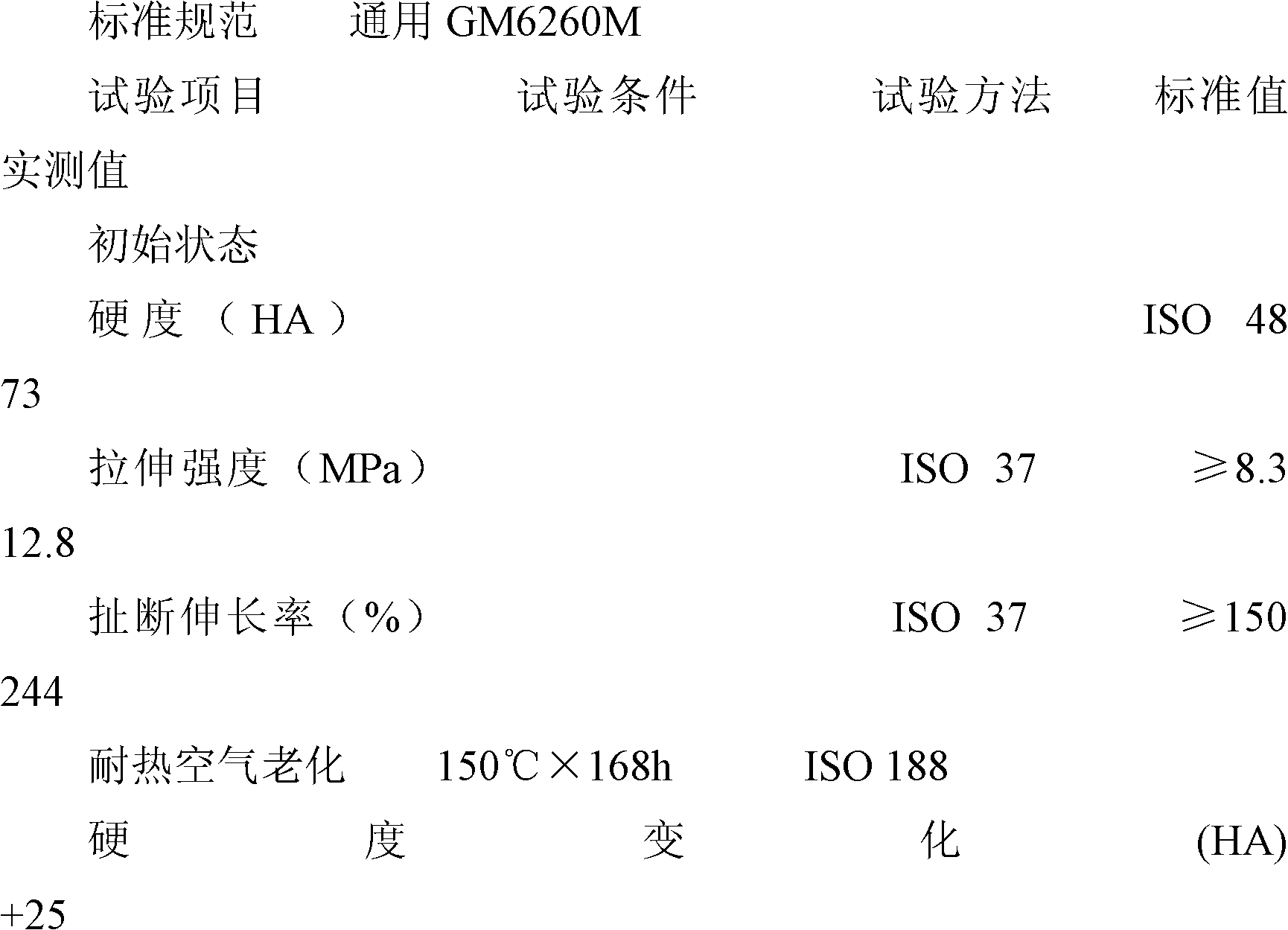

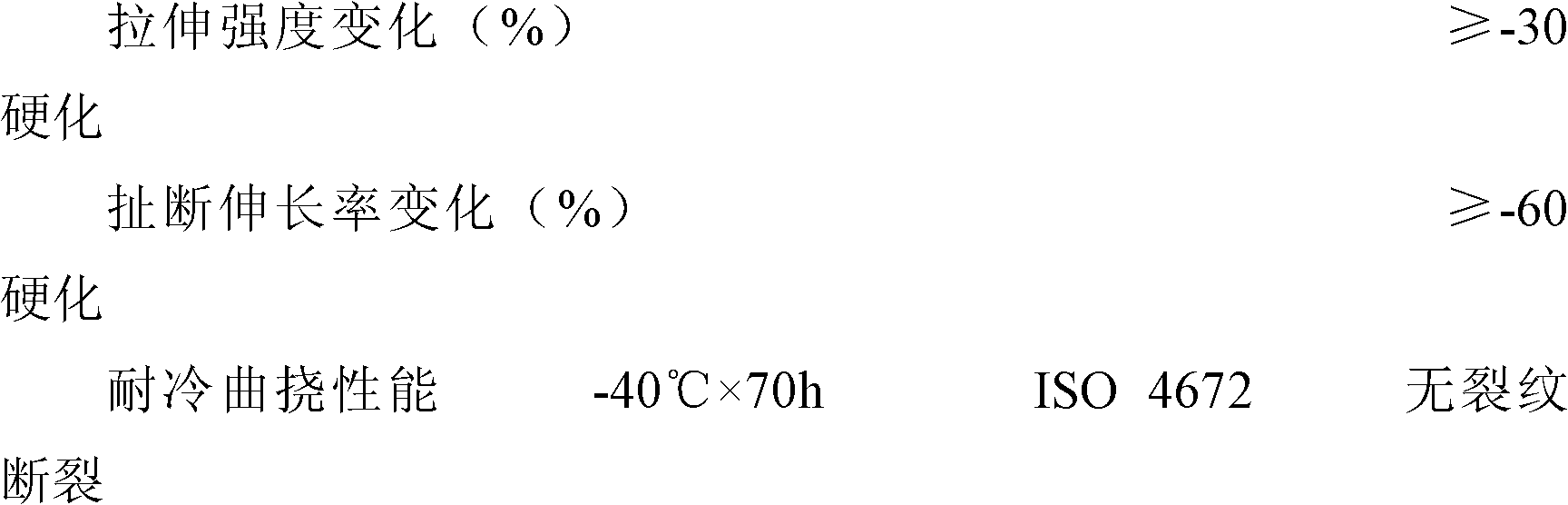

Embodiment 1

[0035] Rubber raw material: chlorinated polyethylene rubber 41.75%;

[0036] Reinforcing filler: 10.44% of quick-pressed furnace black, 14.61% of non-polluting high-definition semi-reinforcing furnace black, and 12.53% of light calcium carbonate;

[0037] Plasticizer: 4.18% dioctyl sebacate, 6.26% trioctyl trimellitate;

[0038] Vulcanizing agent: dicumyl peroxide 2.09%;

[0039] Active agent: highly active magnesium oxide 4.18%, stearic acid 0.63%, triallyl isocyanurate 1.67%;

[0040] Antiaging agent: 0.63% of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0.63% of nickel dibutyl disulfide carbamate;

[0041] Lubricant: polyethylene wax 0.40%;

[0042] The preparation method of the rubber material for preparing high and low temperature resistant automobile pipeline rubber products of the present invention comprises the following steps:

[0043] (1) Cool the internal mixer with water, control the temperature of the internal mixer studio to <100°C, and the rotating speed: 3...

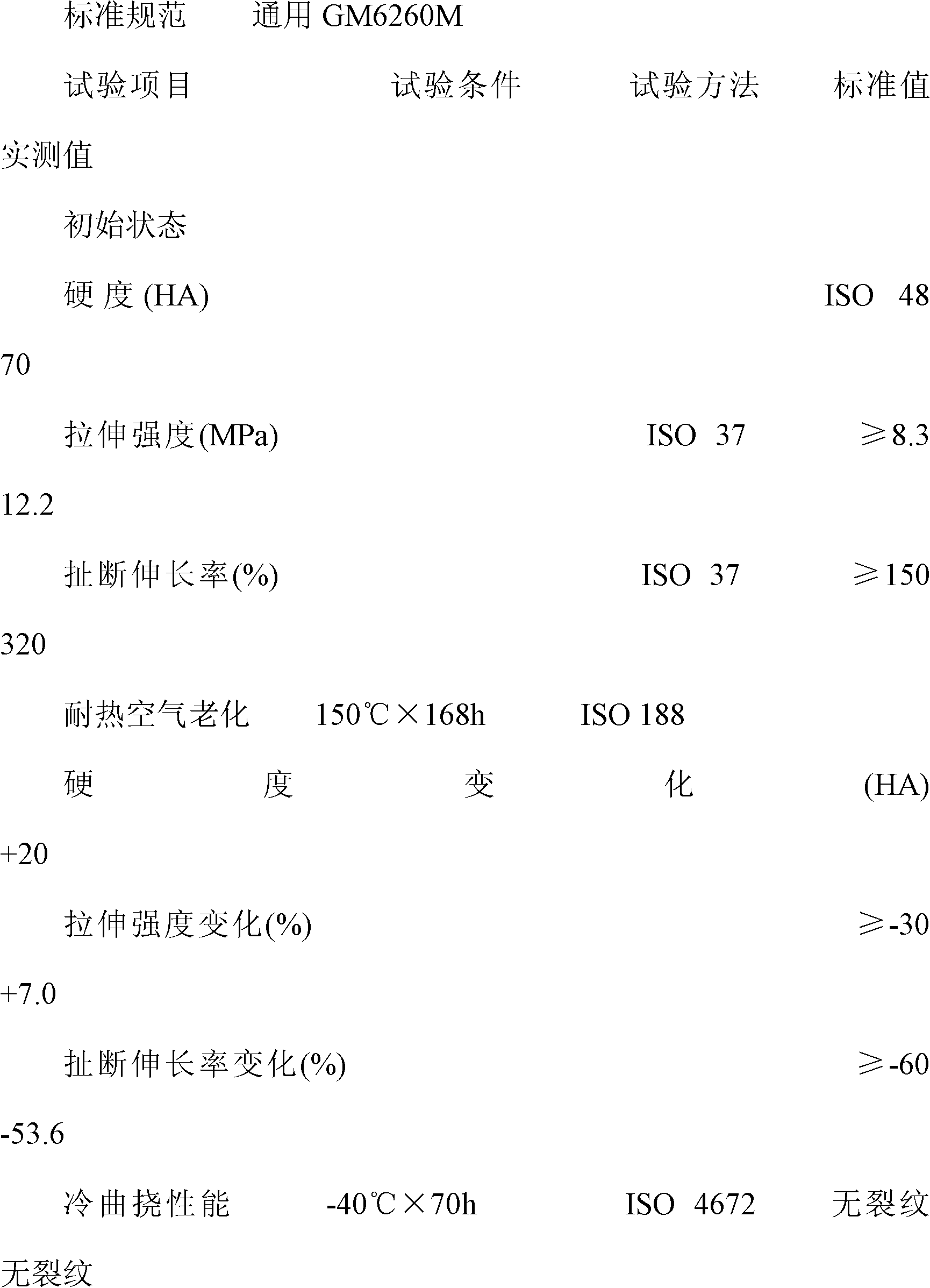

Embodiment 2

[0049] Rubber raw material: chlorinated polyethylene rubber 42.50%;

[0050] Reinforcing filler: 10.30% of quick-pressed furnace black, 14.59% of non-polluting high-definition semi-reinforcing furnace black, and 12.45% of light calcium carbonate;

[0051] Plasticizer: 3.86% dioctyl sebacate, 6.01% trioctyl trimellitate;

[0052] Vulcanizing agent: dicumyl peroxide 2.14%;

[0053] Active agent: highly active magnesium oxide 4.25%, stearic acid 0.60%, triallyl isocyanurate 1.71%;

[0054]Antiaging agent: 0.60% of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0.60% of nickel dibutyl disulfide carbamate;

[0055] Lubricant: polyethylene wax 0.39%;

[0056] The preparation method of the rubber material for preparing high and low temperature resistant automobile pipeline rubber products of the present invention comprises the following steps:

[0057] (1) Cool the internal mixer with water, control the temperature of the internal mixer studio to <100°C, and the rotating speed: 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com