Pomegranate effervescent tablets and preparation method thereof

A technology of effervescent tablets and pomegranate, applied in the field of pomegranate effervescent tablets and its preparation, can solve the problems of difficult removal of tannin, easy oxidation of concentrated pomegranate juice processing, inconvenient carrying of pomegranate powder, etc., and achieves a simple preparation method Feasible, user-friendly, and added-value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

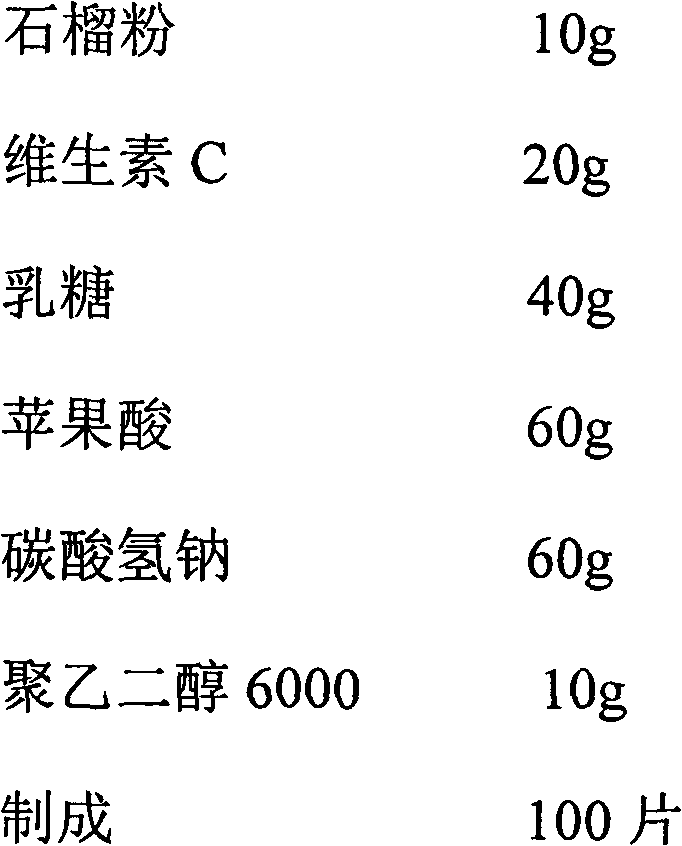

[0042] 1. Group ratio:

[0043]

[0044] 2. Preparation method:

[0045] ① Pass the pomegranate powder through an 80-mesh sieve and store it in a sealed container for later use; dry the malic acid and sodium bicarbonate at 80°C for 2 hours, crush it through a 100-mesh sieve, and store it in an airtight container for later use; pass lactose and polyethylene glycol 6000 through a 100-mesh sieve, Store in a desiccator for later use.

[0046] ②Mix the pomegranate powder, lactose, malic acid, sodium bicarbonate and polyethylene glycol 6000 prepared above, and then press the above powder into 100 pomegranate effervescent tablets under the condition that the pressure of the tablet is controlled to be 5 kg .

[0047] The above-mentioned preparation processes are all carried out in an environment at 20° C. and a humidity of 35%.

[0048] The average tablet weight of the obtained pomegranate effervescent tablet is 2g ± 0.1g, and the surface is smooth. Put a pomegranate effervesce...

Embodiment 2

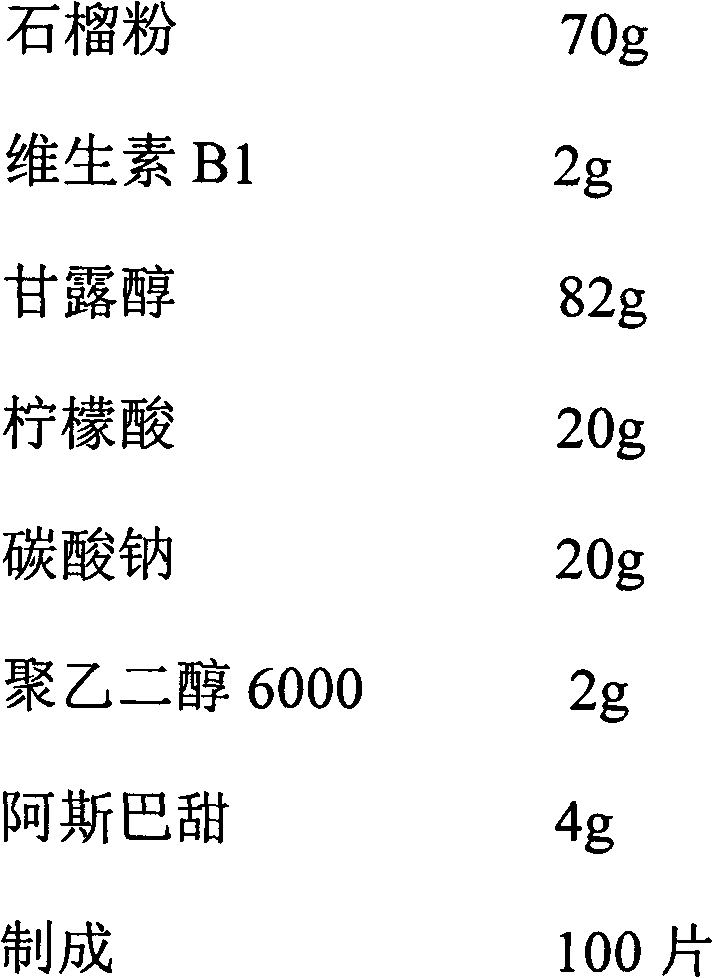

[0050] 1. Group ratio:

[0051]

[0052] 2. Preparation method:

[0053] ① Pass the pomegranate powder through a 60-mesh sieve and store it in airtight storage for later use; dry citric acid and sodium carbonate at 80°C for 2 hours, crush it through a 100-mesh sieve, and store it in an airtight store for later use; mix vitamin B1, mannitol, aspartame, polyethylene glycol Glycol 6000 is passed through a 100-mesh sieve, and stored in a desiccator for subsequent use.

[0054] ②Mix citric acid, vitamin B1 and pomegranate powder evenly and make soft material with 20% ethanol solution, and granulate with 20 mesh sieve; then dry the granulated granules at 50°C for 1 hour; The granules were sieved to obtain granule A.

[0055] ③Mix sodium carbonate, mannitol and aspartame evenly and make soft material with 20% ethanol solution, and granulate with 20 mesh sieve; then dry the granulated granules at 50°C for 1 hour; then dry the dried granules Sizing with a 20-mesh sieve to obtain ...

Embodiment 3

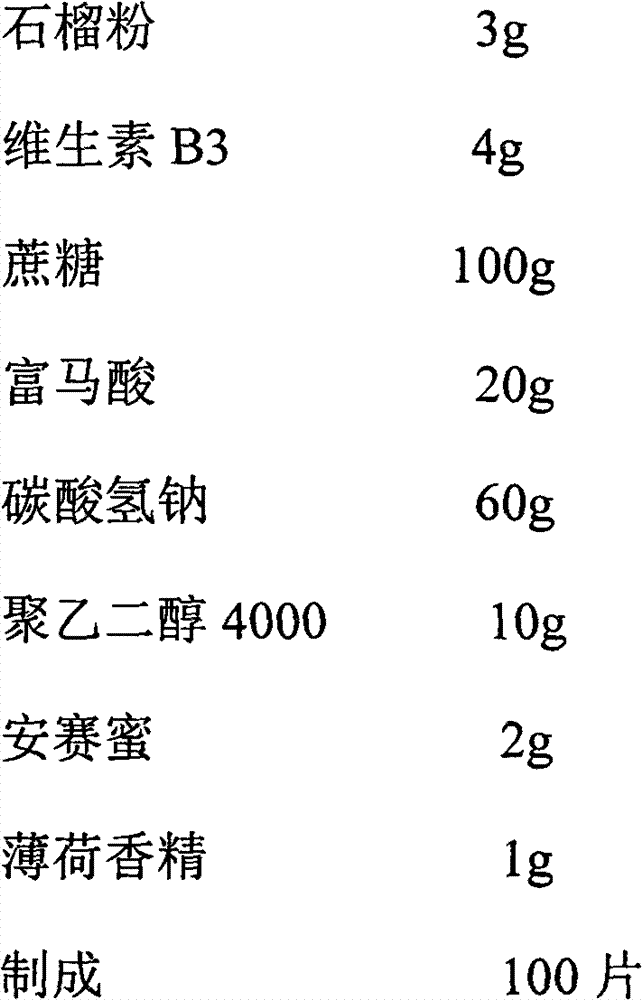

[0060] 1. Group ratio:

[0061]

[0062] 2. Preparation method:

[0063] ① Pass the pomegranate powder through a 100-mesh sieve and store it in airtight storage for later use; dry fumaric acid and sodium bicarbonate at 80°C for 2 hours, crush them through a 100-mesh sieve, and store them in airtight storage for later use; mix vitamin B3, sucrose, polyethylene glycol 4000, Acesulfame K and peppermint essence are passed through a 100-mesh sieve, and stored in a desiccator for later use.

[0064] ②Mix the pomegranate powder with vitamin B3, fumaric acid, sodium bicarbonate, sucrose, and acesulfame K evenly, and make a soft material with anhydrous ethanol solution, and granulate with a 20-mesh sieve; then dry the granulated granules at 50°C 1 hour,;

[0065] The dried granules are then sized with a 20-mesh sieve.

[0066] ③ Add polyethylene glycol 4000 and peppermint essence to the sized granules, and mix well.

[0067] ④The mixture was pressed into tablets, and the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com