Red flower harvester

A technology of safflower and flower boxes, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of lower income for drug farmers, large labor demand, and reduced safflower planting area, so as to improve harvesting efficiency and reduce Less labor intensity and less plant damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

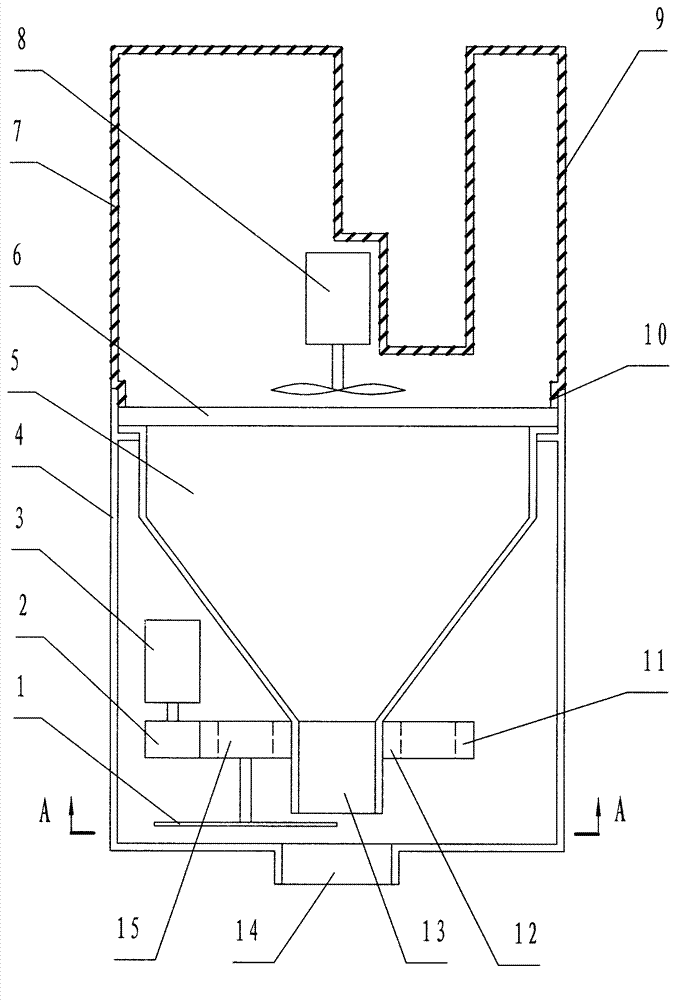

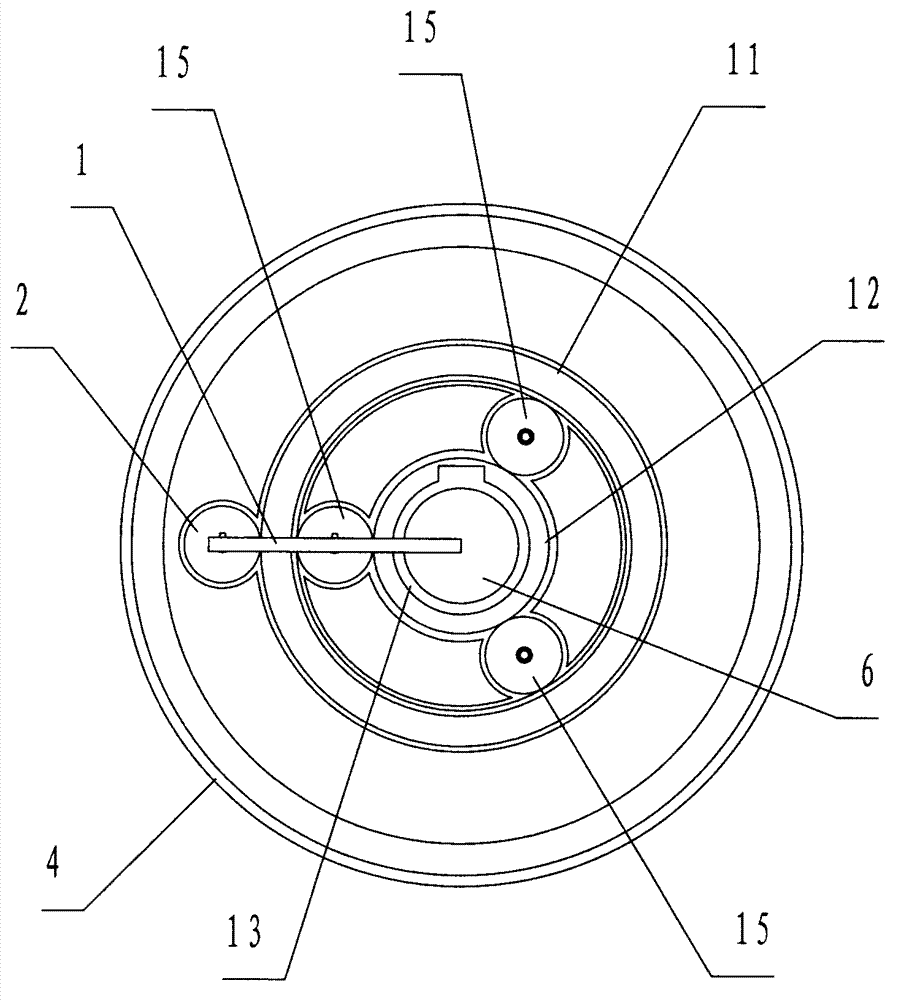

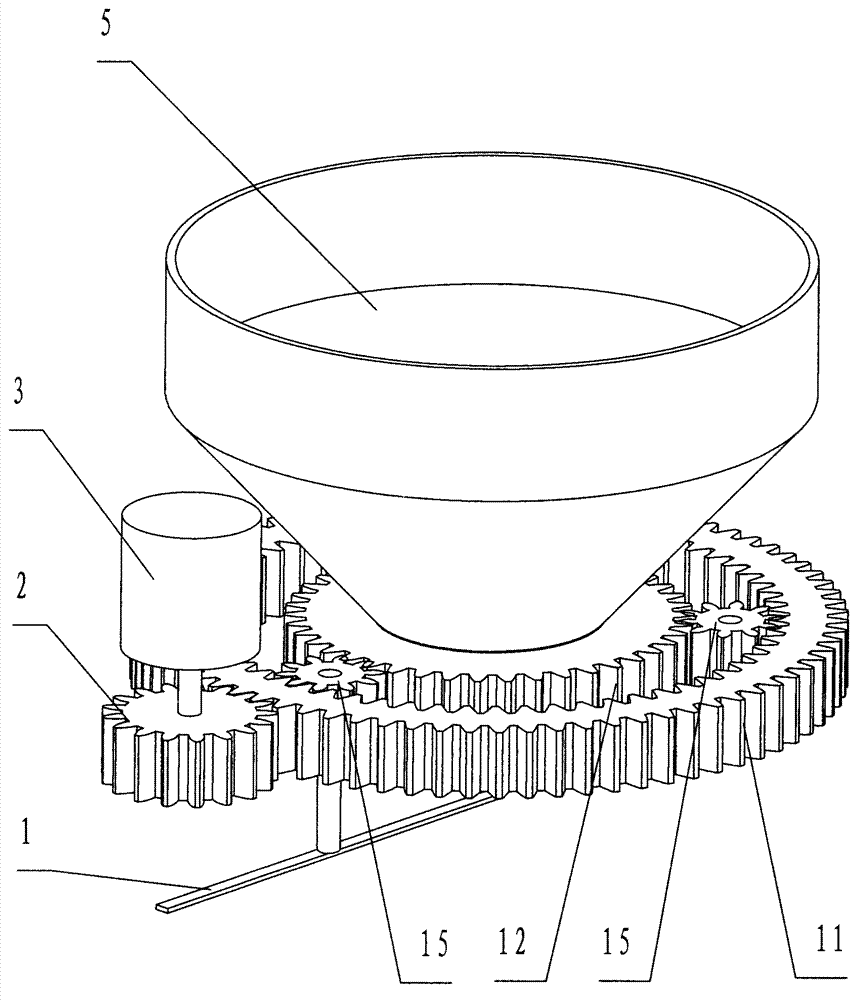

[0014] Embodiment 1: with reference to attached Figure 1~3 , the present embodiment comprises an upper case 7, a lower case 4, a negative pressure blower 8 is arranged in the upper case 7, a filter screen 6 is arranged under the negative pressure blower 8, a hand-held part 9 is integrally connected with the upper case 7, and the lower case 4 is provided with suction flower box 5, and suction flower box 5 is provided with power motor 3 outside, and power motor 3 is provided with power gear 2, and suction flower box 5 is provided with revolving gear 11, and revolution gear 11 is an inner and outer ring gear, Power gear 2 and revolving gear 11 are on the same horizontal plane, and revolving gear 11 meshes with power gear 2, and revolving gear 11 is provided with the central gear 12 that wheel diameter is less than revolving gear 11 wheel diameters, and revolving gear 11 and central gear 12 are provided with There are three equal-diameter planetary gears 15, the planetary gears 1...

Embodiment 2

[0015] Embodiment 2: Compared with Embodiment 1, the difference is that the movable connection between the upper case 7 and the lower case 4 is threaded, the handle 9 on the upper case 7 is a handle, and the three planetary gear shafts Cutting knives 1 are respectively arranged below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com