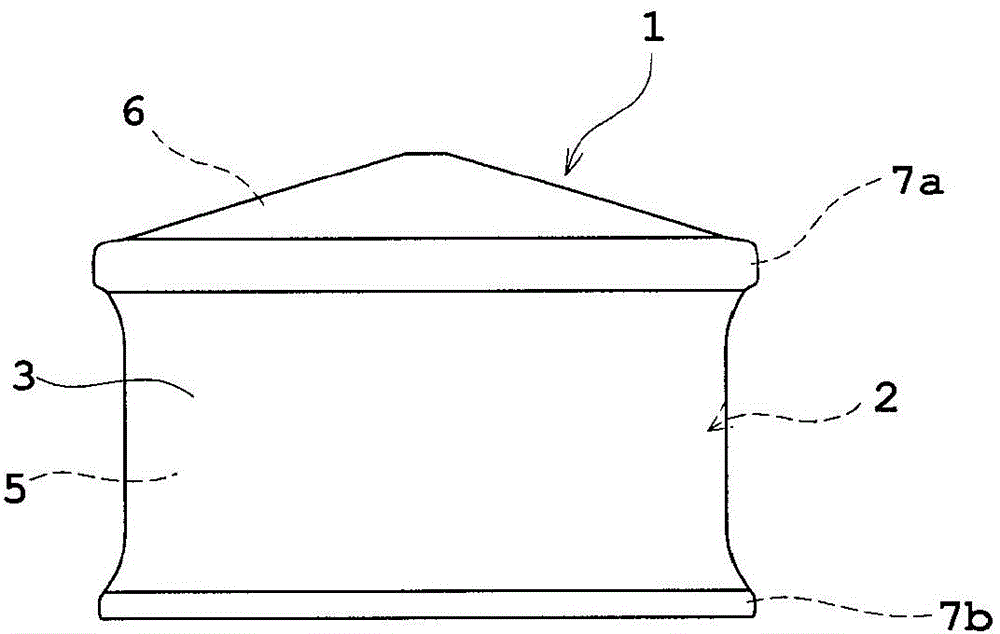

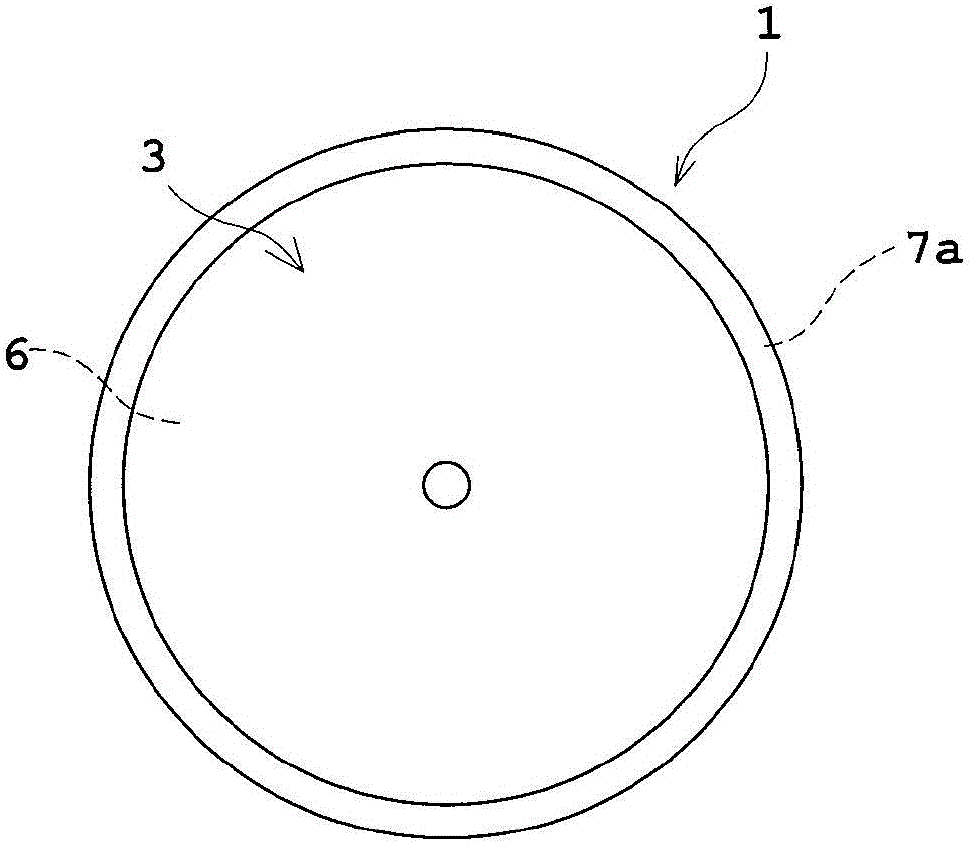

Medical device with slideable coating, and syringe

A technology of medical appliances and covering layers, which is applied in the field of medical appliances, can solve the problems of insoluble particles and achieve good sliding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] (ingredient 1a)

[0098] Weigh 125g of octamethylcyclotetrasiloxane, 5g of 1,3,5,7-tetravinyltetramethylcyclotetrasiloxane, and 2.5g of dodecane in a 300mL tall beaker Benzenesulfonic acid and 22.5 g of water were stirred with a homomixer at a rotation speed of 6,000 rpm for 10 minutes, and then 100 g of water was gradually added at a rotation speed of 2,000 rpm to perform rough emulsification. After degassing under reduced pressure, use a pressure homogenizer at a pressure of 300kg / cm 2 The emulsification was carried out twice under the conditions. The refined emulsion was reacted at 70°C for 6 hours, then kept at 15°C for 12 hours for emulsion polymerization, and the polymerization was completed by adjusting the pH to 6.0 with 10% aqueous sodium carbonate solution. The polysiloxane obtained by polymerization had a molecular weight of 330,000 and a vinyl content of 4.5 wt%. The resulting preparation was used as component 1a.

[0099] (ingredient 1b)

[0100] In a ...

Embodiment 2

[0108] (ingredient 1a)

[0109] In addition to changing 5 g of 1,3,5,7-tetravinyltetramethylcyclotetrasiloxane in Example 1 into 10 g of 1,3,5,7-tetravinyltetramethylcyclotetrasiloxane Except for alkane, it was carried out in the same manner as in Example 1, and the obtained preparation product was used as component 1a. Wherein, the polysiloxane obtained by polymerization has a molecular weight of 310,000 and a vinyl content of 5.4 wt%.

[0110] (ingredient 1b)

[0111] The prepared product obtained in the same manner as in Example 1 was used as component 1b.

[0112] (ingredient 2)

[0113] The prepared product obtained in the same manner as in Example 1 was used as component 2.

[0114] (ingredient 3)

[0115] As component 3, phenyltriethoxysilane, γ-ureidopropyltriethoxysilane, and γ-glycidoxypropyltrimethoxysilane were used.

[0116] (coating solution)

[0117] Mix 100 g of component 1a, 6.8 g of component 1b, 0.34 g of component 2, 1 g of phenyltriethoxysilane of c...

Embodiment 3

[0119] (ingredient 1a)

[0120] In addition to changing 5 g of 1,3,5,7-tetravinyltetramethylcyclotetrasiloxane in Example 1 into 1 g of 1,3,5,7-tetravinyltetramethylcyclotetrasiloxane Except for alkane, it was carried out in the same manner as in Example 1, and the obtained preparation product was used as component 1a. Wherein, the polysiloxane obtained by polymerization has a molecular weight of 350,000 and a vinyl content of 3.8 wt%.

[0121] (ingredient 1b)

[0122] The prepared product obtained in the same manner as in Example 1 was used as component 1b.

[0123] (ingredient 2)

[0124] The prepared product obtained in the same manner as in Example 1 was used as component 2.

[0125] (ingredient 3)

[0126] As component 3, phenyltriethoxysilane, γ-ureidopropyltriethoxysilane, and γ-glycidoxypropyltrimethoxysilane were used.

[0127] (coating solution)

[0128] Mix 100 g of component 1a, 0.68 g of component 1b, 0.17 g of component 2, 1 g of phenyltriethoxysilane of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com