Method for modeling multi-scale finite element model of node of steel framework structure

A technology of structural nodes and model modeling, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the inability to balance calculation accuracy and calculation cost, and achieve the effect of reducing calculation cost and ensuring calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

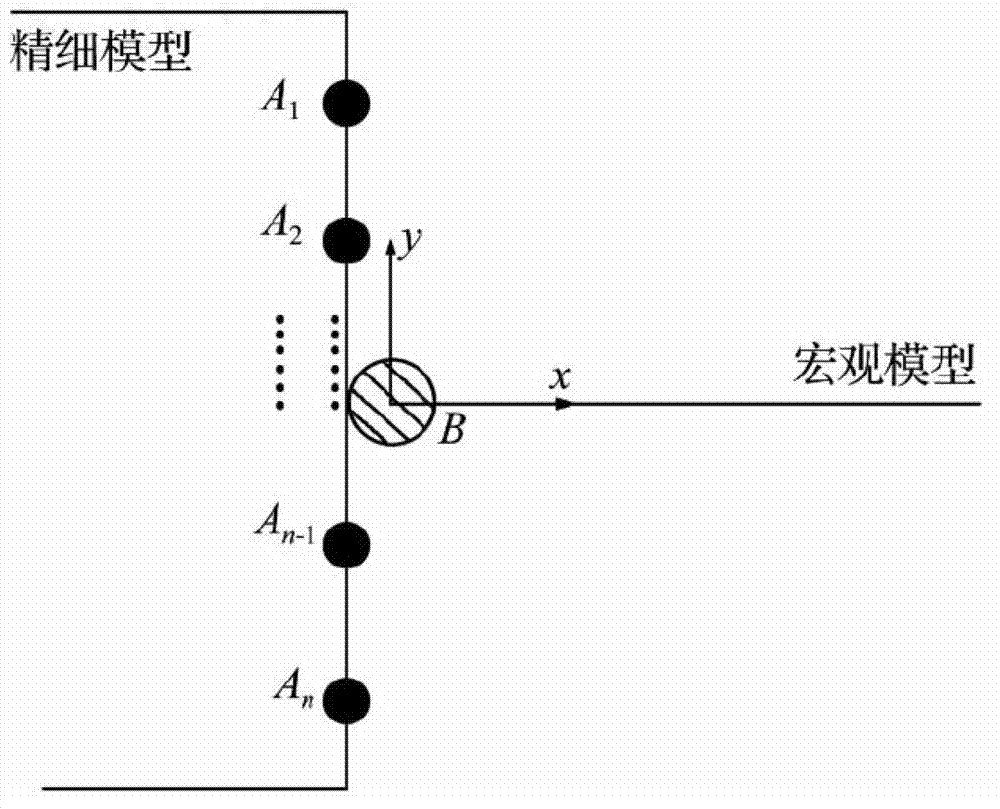

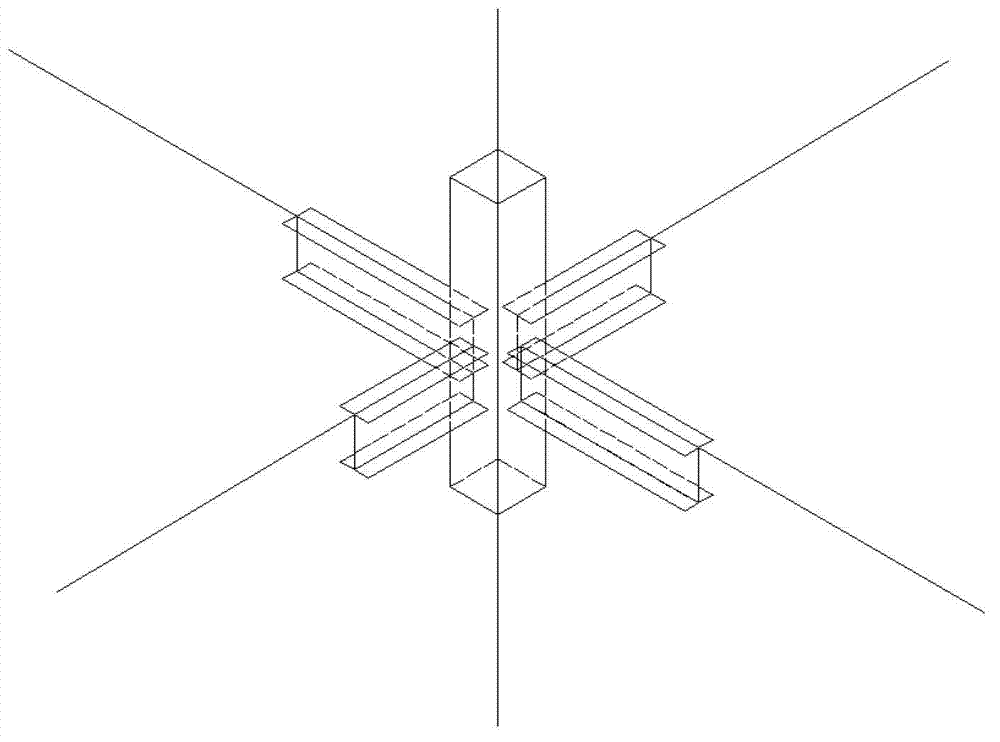

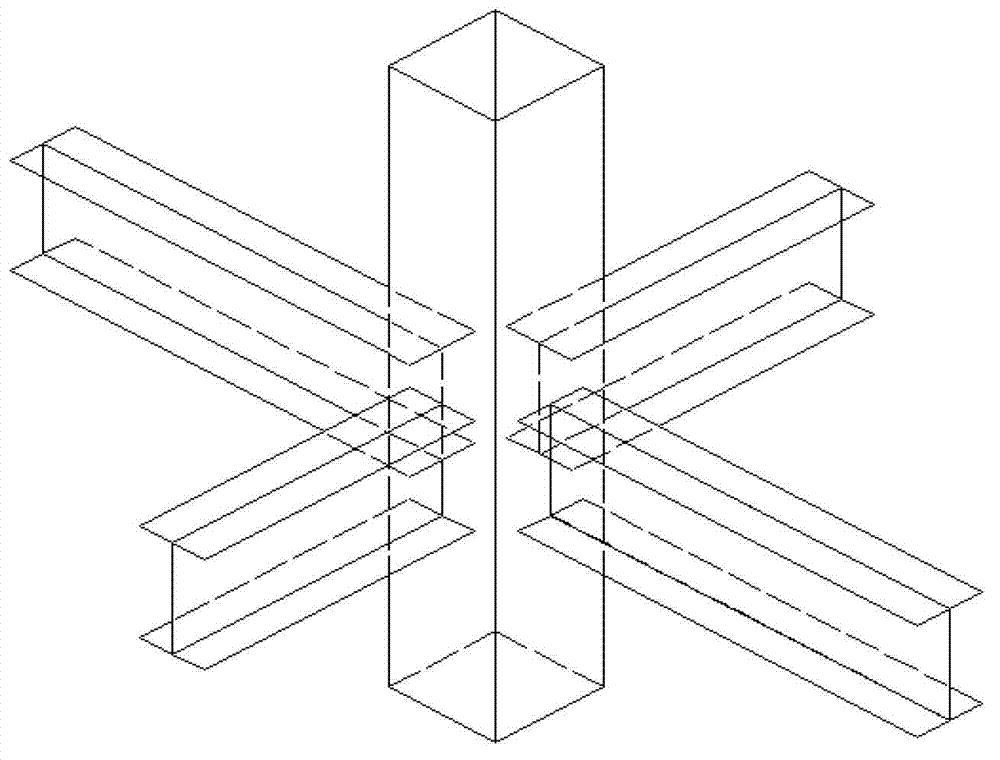

[0037] refer to Figure 1 ~ Figure 4 , a method for modeling a multi-scale finite element model of a steel frame structure node, the method comprising the following steps:

[0038] 1) Using finite element analysis software (including MIDAS GEN, SAP2000, ANSYS, ABAQUS, etc.), adopting one-dimensional beam elements to establish a steel frame structure calculation model, selecting key beam-column nodes, and intercepting the beams at the key beam-column nodes unit, the axial length of the intercepted beam unit can be taken as (5~8) times the height or diameter of the member section (the maximum size of the outer contour of the member section), delete this part of the intercepted beam unit, and use the two-dimensional plate provided by the above-mentioned finite element software The shell element simulates the plate of the beam-column member and the stiffener of the node d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com