Bearing cover for crank circular slider mechanism as well as internal-combustion engine and compressor using bearing cover

A technology of crank round slider and bearing cap, applied in the fields of bearing caps and compressors, can solve problems such as difficulty in setting reciprocating motion orbits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

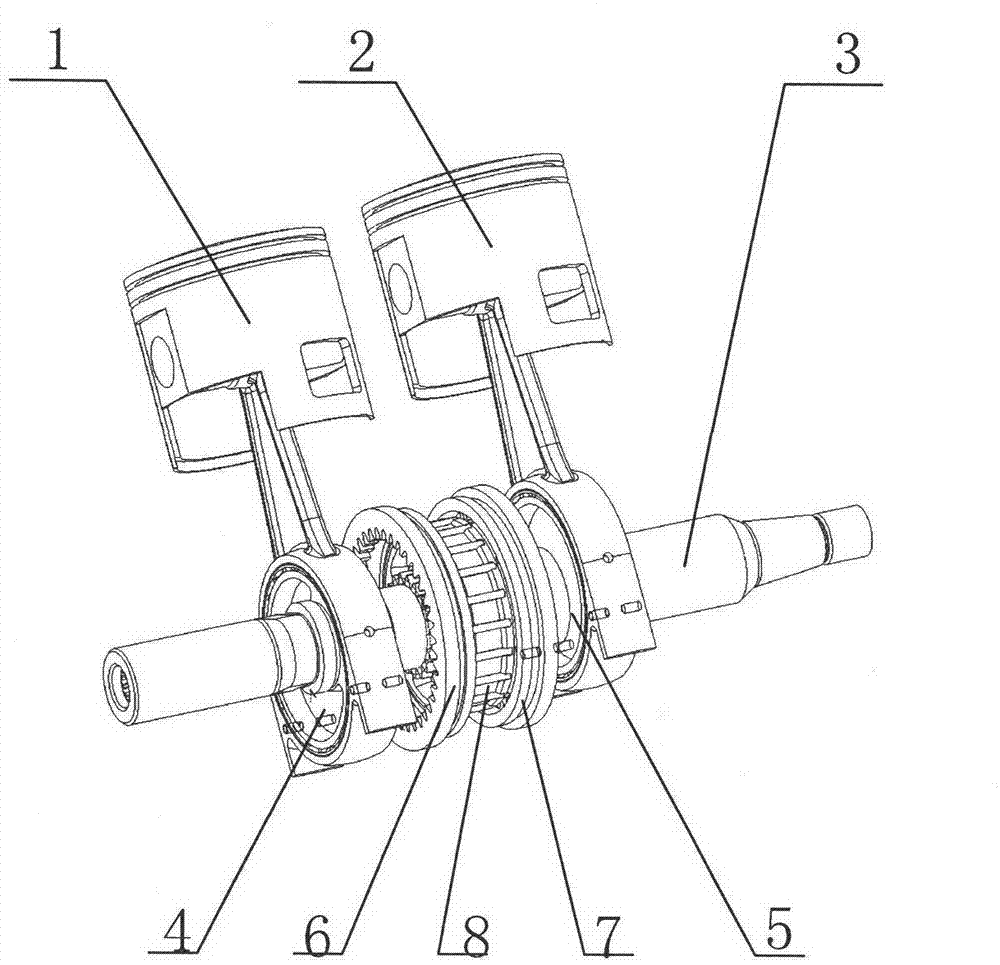

[0031] Please see figure 1 , which is one of the three-dimensional views of the structure of the crank-slider mechanism applied to the bearing cover of the crank-slider mechanism provided by the embodiment of the present invention; please also refer to figure 2 , which is the second structural perspective view of the crank circular slider mechanism.

[0032] like figure 1 , figure 2 As shown, the crank and slider mechanism includes a first piston 1 , a second piston 2 , a crankshaft 3 , a first slider 4 , a second slider 5 , a first ring gear 6 and a second ring gear 7 . The above-mentioned components are introduced respectively below.

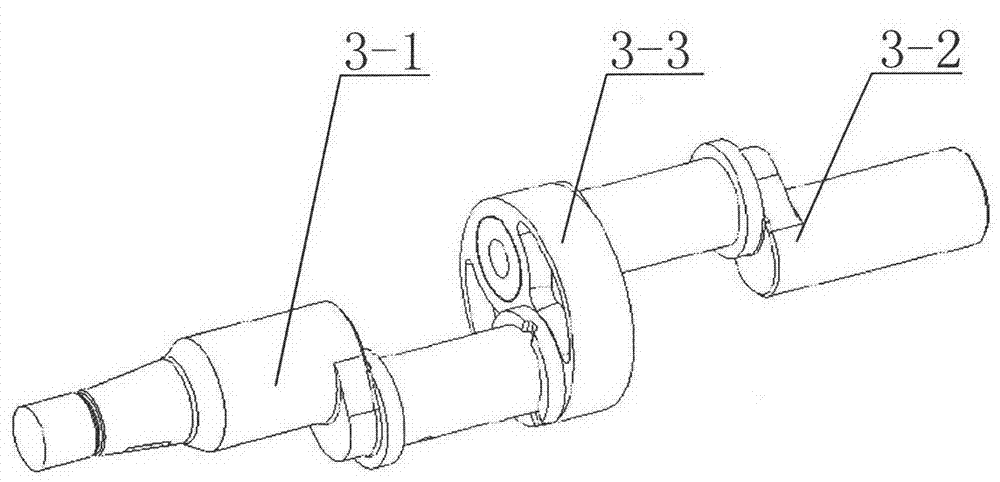

[0033] Please see image 3 , which shows the structure of the crankshaft 3 .

[0034] As shown in the figure, the crankshaft 3 is a split crankshaft, including a first crankshaft segment 3-1, a second crankshaft segment 3-2 and an intermediate crank 3-3.

[0035] Please see Figure 4 , which is a perspective view of the middle crank 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com