mine dump truck

A technology of mining dump truck and frame, which is applied to vehicle parts, vehicles with inclined bearing motion, elastic suspension, etc. Costs and operating costs, the effect of reducing fuel consumption and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

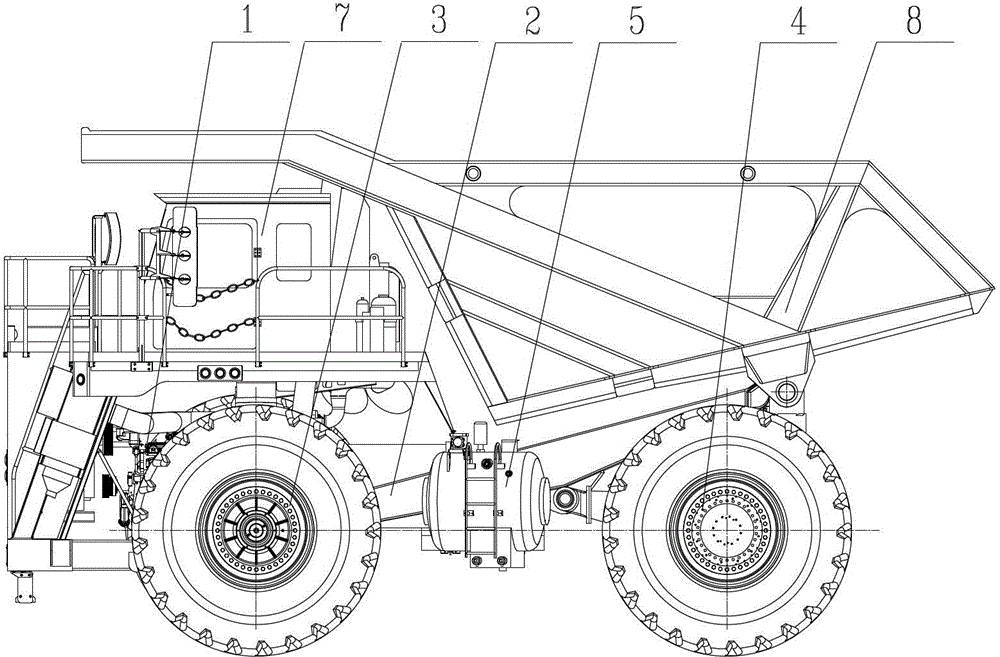

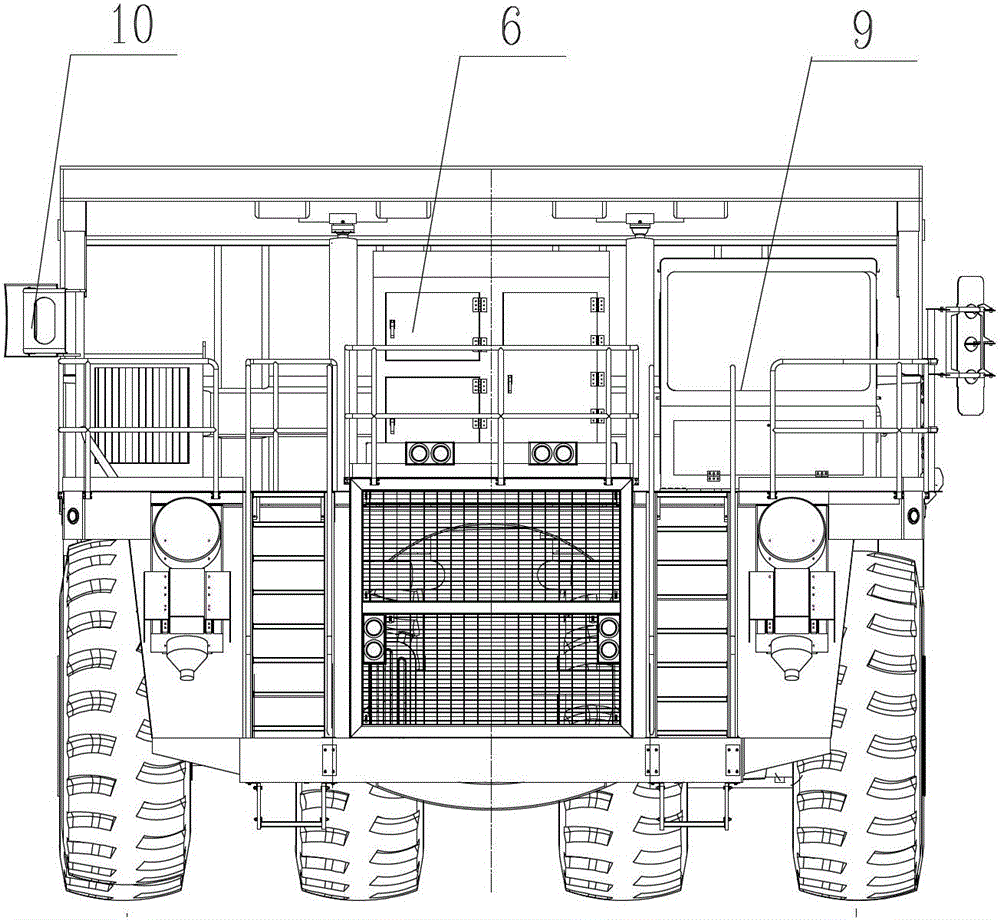

[0029] Such as figure 1 with figure 2 As shown, the electric wheel mining dump truck carrying 110 tons in this embodiment mainly includes a power system 1, a vehicle frame 2, a front axle 3, a rear axle 4, a hydraulic system 5, an electric drive system 6, a cab 7, and a cargo box 8. Vehicle management control system 9 and auxiliary system 10.

[0030] Among them, the power system 1 is mainly composed of an engine, a generator, a subframe, a cooling system, an air intake system, an exhaust heating / silencing system, and an oil supply system. The power system 1 is arranged at the front of the vehicle frame 2 . The fuel consumption value of the mining dump truck developed by the invention is 0.03L / (t·km), which is far lower than the standard requirement of "the fuel consumption value is not greater than 0.048L / (t·km)".

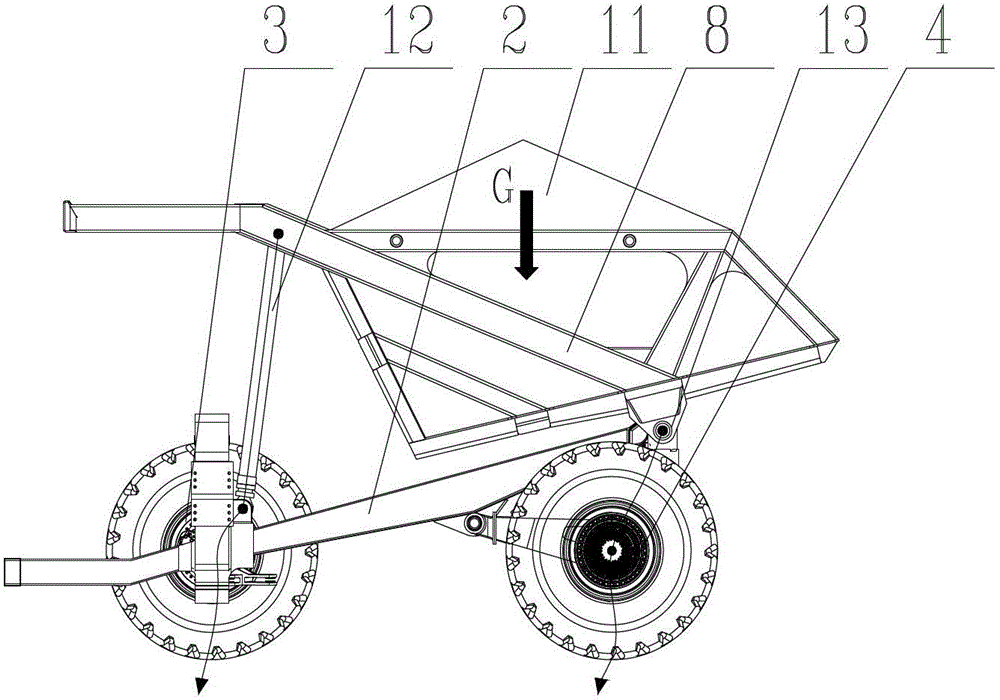

[0031] Such as Figure 4As shown, the vehicle frame 2 includes a front beam 21 , a middle beam 25 , an annular ring beam 27 , a left side beam 22 and a right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com