Glass fiber reinforced plastic round pipe double-head pultrusion winding equipment

A technology of reinforced plastics and glass fiber, which is applied in the field of production equipment of glass fiber reinforced plastic round pipes, can solve problems such as mandrel growth, increase the distance between the mandrel fixing mechanism and the outer mold cavity, and unstable product eccentricity. The control and transfer are convenient and fast, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] combined with Figure 1-Figure 4 The present invention is further described:

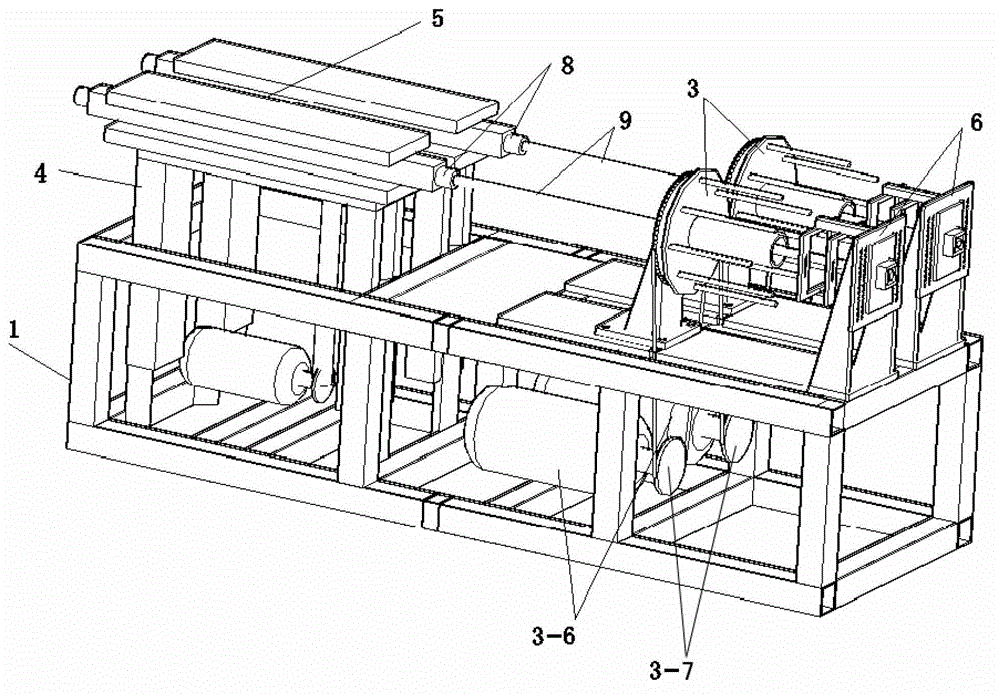

[0019] A glass fiber reinforced plastic round tube double-headed wrapping device described in the present invention is as follows: figure 1 As shown, it includes a frame 1, a round pipe mold 8, a lifting mechanism 4, a mandrel fixing mechanism 6, a winding mechanism 3, a mandrel 9 and a heating plate 5.

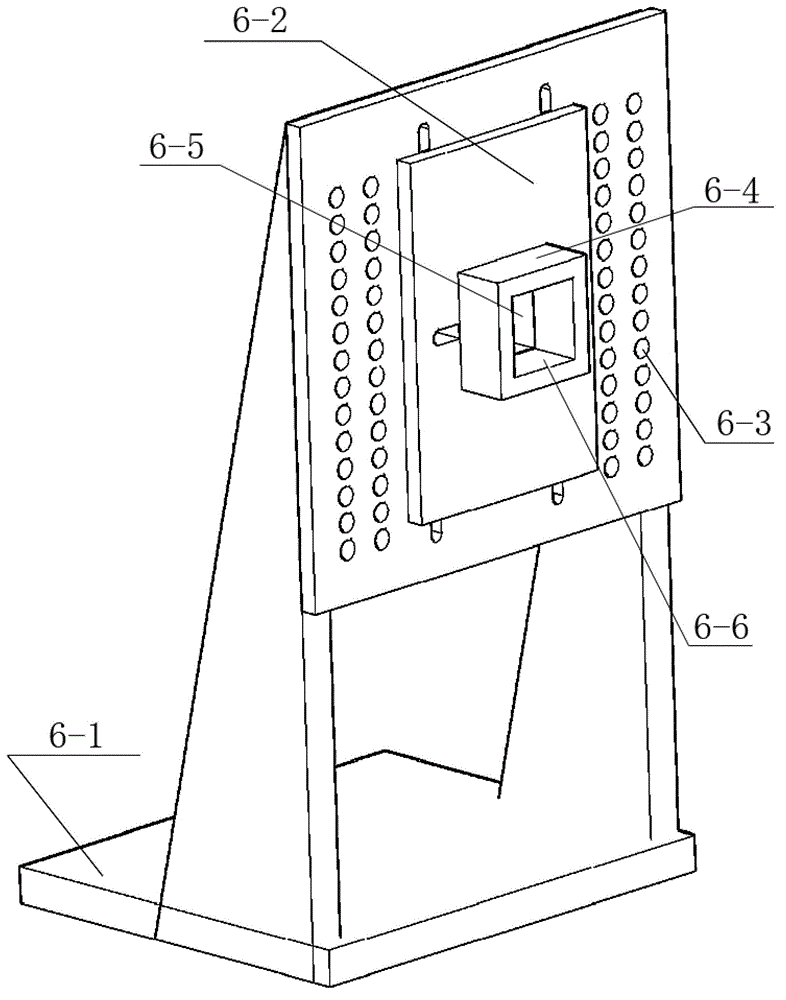

[0020] The fixing mechanism 6 includes a base 6-1, a first adjusting plate 6-2, and a second adjusting plate 6-4.

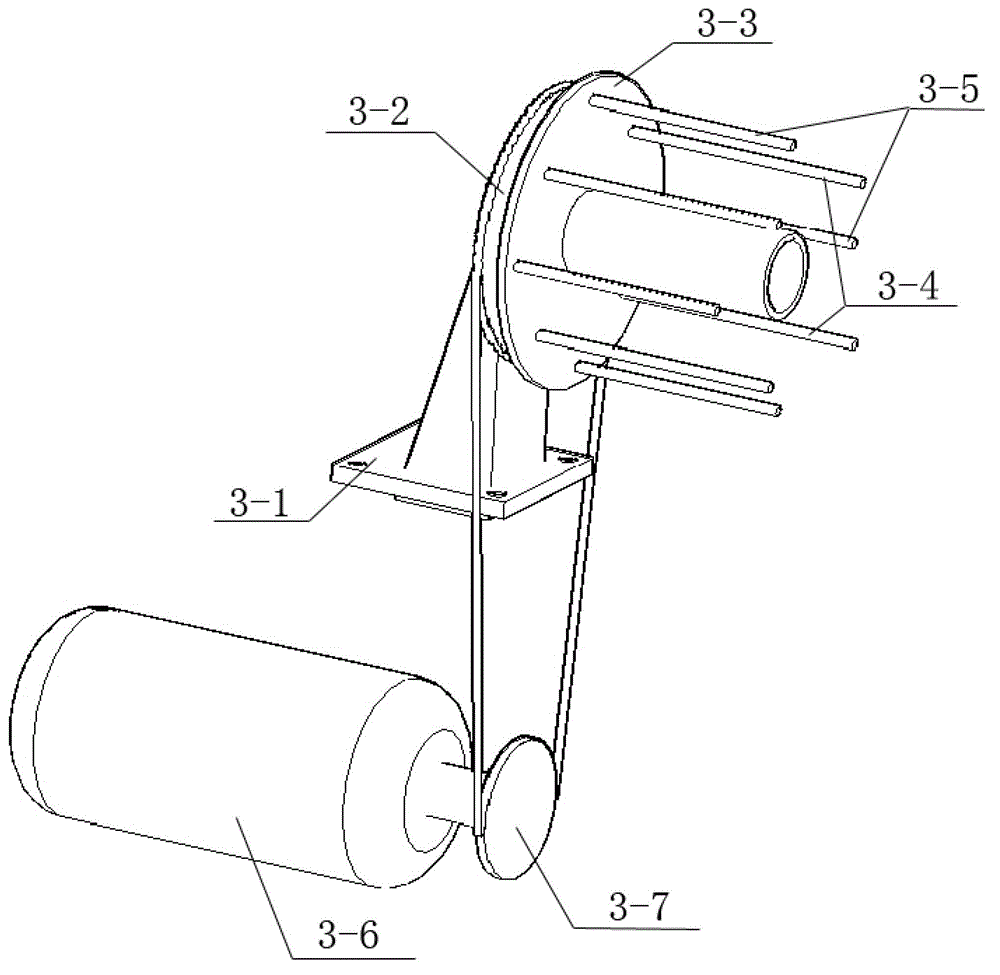

[0021] The winding mechanism 3 comprises a base 3-1, a transmission disc 3-2, a rotating disc 3-3, a bobbin fixing rod 3-4, a yarn tension arrangement rod 3-5, a driving motor 3-6 and a driving disc 3-7.

[0022] Frame 1 is used for fixing and installing circular pipe mold 8, lifting mechanism 4, mandrel fixing mechanism 6 and winding mechanism 3 with whole equipment. Rack 1 has a length of 3.0 meters. The total length of frame 1 is 3 meters, that is, the length of the mand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com