Vertical automatic mounting device for connector push rods

A technology of automatic installation and connectors, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of large space occupation, not in line with the development direction of environmental protection, and lack of economic practicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

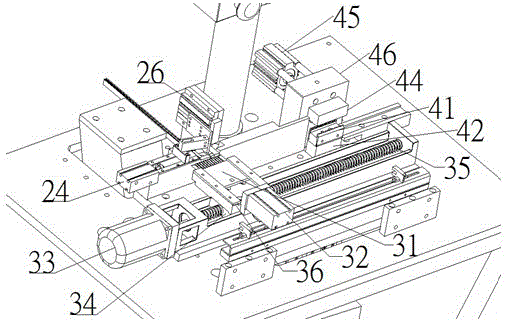

[0018] To facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

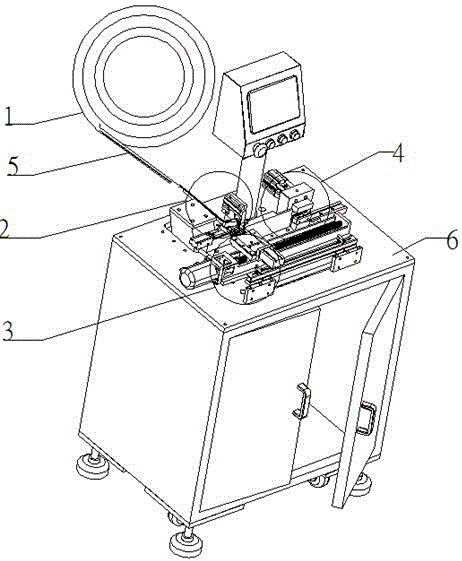

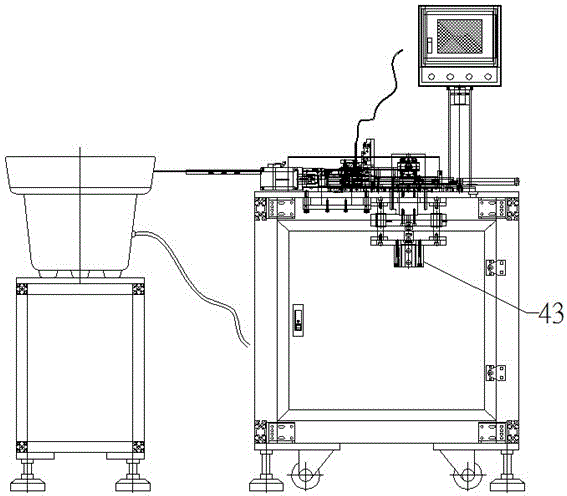

[0019] The device disclosed in this embodiment can complete the automatic assembly operation of the entire assembly process of the connector push rod. Compared with the traditional structure, its structure occupies less space, is convenient to install, and has low cost. At the same time, on the basis of ensuring the processing quality, the The single cycle of the device can realize the assembly of multiple connector push rods, the processing speed is fast, and the production efficiency can be doubled.

[0020] The main function of the connector push rod assembly device disclosed in this embodiment is to complete the automatic assembly process of connector push rods in a cycle, and ensure that multiple connector push rods are assembled simultaneously in a single cycle, so as to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com