Automobile instrument desk punching machine

A technology for automotive instruments and punching machines, which is applied in the field of punching machines for automotive instrument panels, can solve the problems of reduced punching efficiency, non-conforming center distance, poor precision, etc., and achieves improved safety, good punching accuracy, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

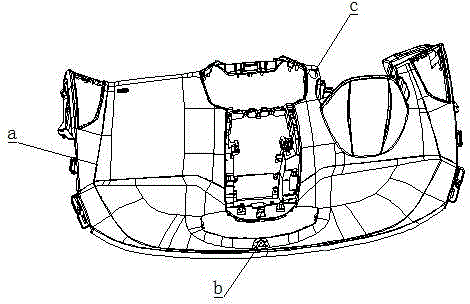

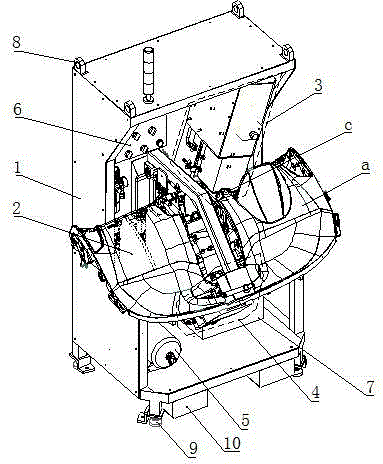

[0023] like figure 2 As shown, the above punching machine for automobile instrument panel mainly includes frame 1, instrument panel support base 2, wiper blade induction mounting hole punching unit 3, lockless start mounting hole punching unit 4, gas storage tank 5, control panel 6. Waste bin 7 and electric control cabinet (not shown in the figure). The top four corners of the frame 1 are provided with lifting lug modules 8, the control panel 6 is installed on the upper left part of the frame 1, the wiper blade induction mounting hole punching unit 3 is installed on the upper right part of the frame 1, and the middle workbench of the frame 1 The instrument panel supporting base 2 is set on the board, the bottom is provided with an air storage tank 5 and a waste box 7, four adjustment feet 9 are installed at the four corners of the bottom of the frame 1, and a pair of forklift grooves 10 are installed at the middle of the bottom. The lockless start mounting hole punching unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com