Splashing preventing and oily water collecting device for pressure cooker

A collection device, pressure cooker technology, applied in pressure cooker, overflow prevention, cooking utensils and other directions, can solve the problems of difficult popularization and application, implementation restrictions, easy to disturb people, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

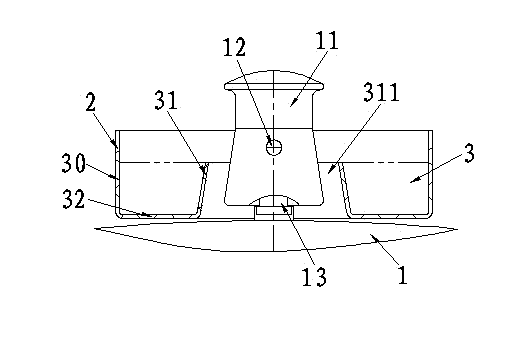

[0026] The anti-splash and oil-water collection device of the cooking pressure cooker according to Embodiment 1 of the present invention (for the structure see figure 1 , figure 2 and Figure 9 ), including a cylinder cover 2 located on the lid 1 of the pressure cooker around the pressure limiting valve to block the mixed fluid sprayed from the pressure limiting valve, and its structural characteristics are:

[0027] The lower part of the cylinder cover 2 is provided with an annular groove-shaped receiving groove 3 on the pot cover 1 surrounding the pressure limiting valve bonnet 11;

[0028] The above-mentioned receiving groove 3 is connected between the outer ring wall 30 integrated with the tube cover 2 and the cylindrical inner ring wall 31 with a through hole 311 located at the inner periphery of the tube cover 2 and integrally connected between the bottom ends of the two. The circular groove bottom 32 encloses and forms;

[0029]The above-mentioned through hole 311 a...

Embodiment 2

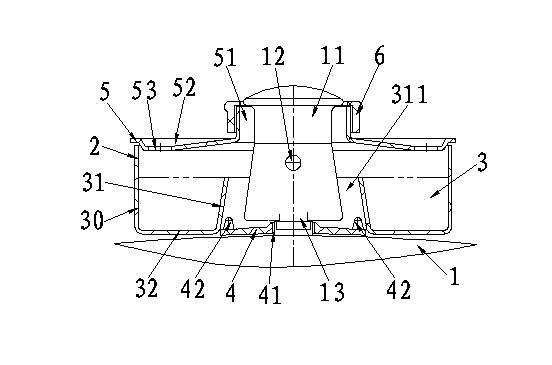

[0039] The anti-splash and oil-water collection device of the cooking pressure cooker according to the second embodiment of the present invention (for the structure see Figure 3 to Figure 5 , Figure 9 and Figure 10 ). On the basis of Embodiment 1 of the present invention, in order to make the function of the device of the present invention more perfect, so as to make it easier to implement and apply, the following structure is further constructed, and its benefits are also described later.

[0040] Further structure 1: On the pot cover 1 located on the inner periphery of the inner ring wall 31 and below the valve cap 11, a sleeve shoulder 4 surrounding the pressure limiting valve is provided; the sleeve shoulder 4 is connected to the sleeve seat 13 through the sleeve hole 41 There is a suitable gap between the sleeve shoulder 4 and the bottom end side of the bonnet 11 for the passage of the mixed fluid; The gap between the sides is uniform and stable. This provides a re...

Embodiment 3

[0050] The anti-splash and oil-water collection device of the cooking pressure cooker according to the third embodiment of the present invention (for the structure see Figure 6 to Figure 10). On the basis of the second embodiment of the present invention, the third embodiment is further configured as follows.

[0051] Above-mentioned cover shoulder 4 is provided with the recessed notch 43 that is positioned at the mouth portion outwards between two adjacent protruding heads 42; The sleeve fork 44 that shoulder 4 is integrally connected, the sleeve fork 44 is positioned at the lower side portion of tank bottom 32 and has suitable height, so that there is suitable space between the lower side of tank bottom 32 and the surface of pot cover 1 to supply oil and water. circulation gap.

[0052] The notch 43 and the gap between the groove bottom 32 and the pot cover 1 provided in this embodiment have the following functions in cooperation: (1). When the pressure cooker using the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com