Arrangement For Cutting Nail Blanks From An Intermittently Fed Wire

A wire and distribution technology, which is applied to the device for shearing and forming blanks, shearing devices, nails, etc., can solve the problems of high mechanical cost and large overall size of the device, and achieve the effect of flexible use and reduced complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

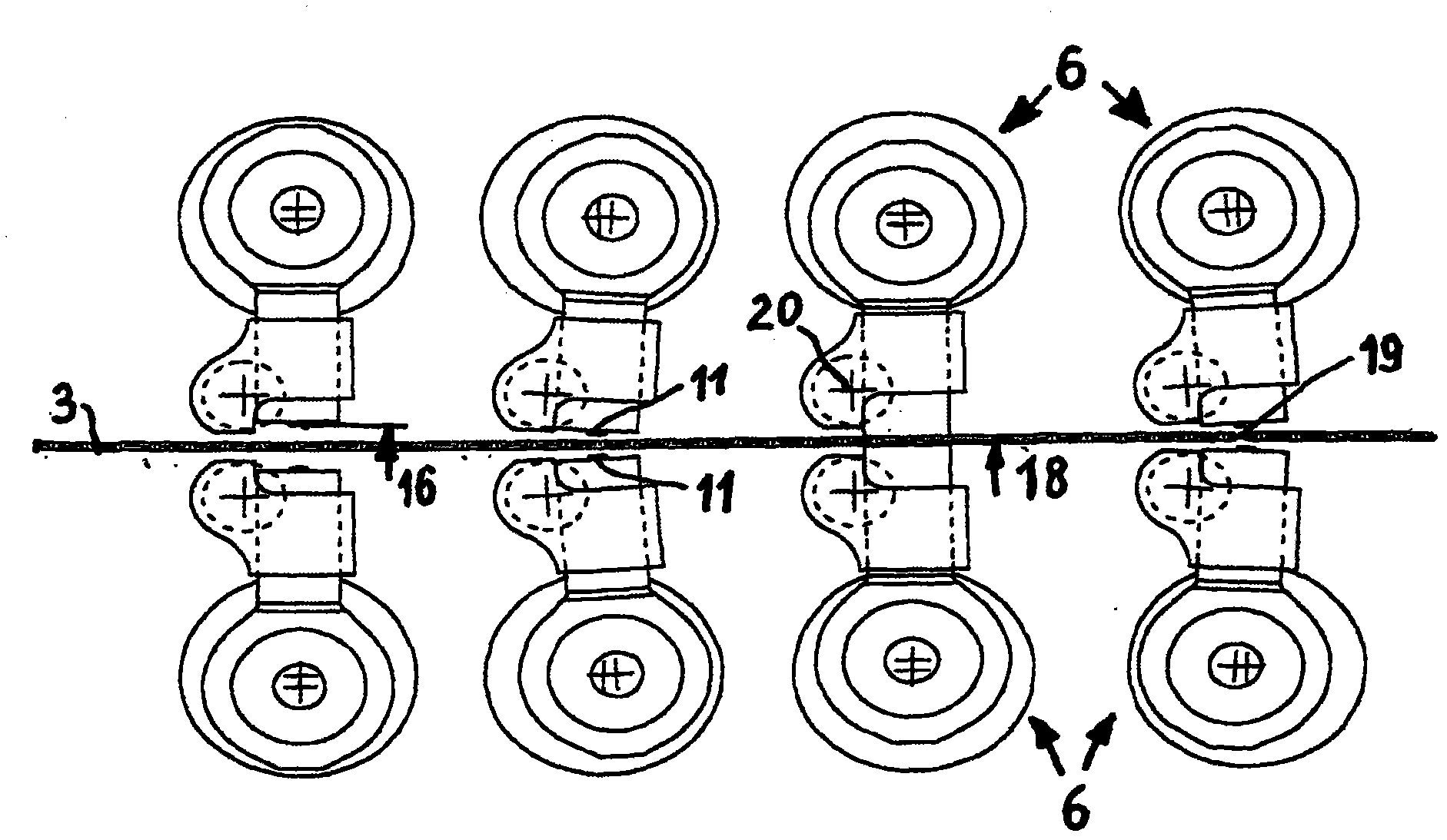

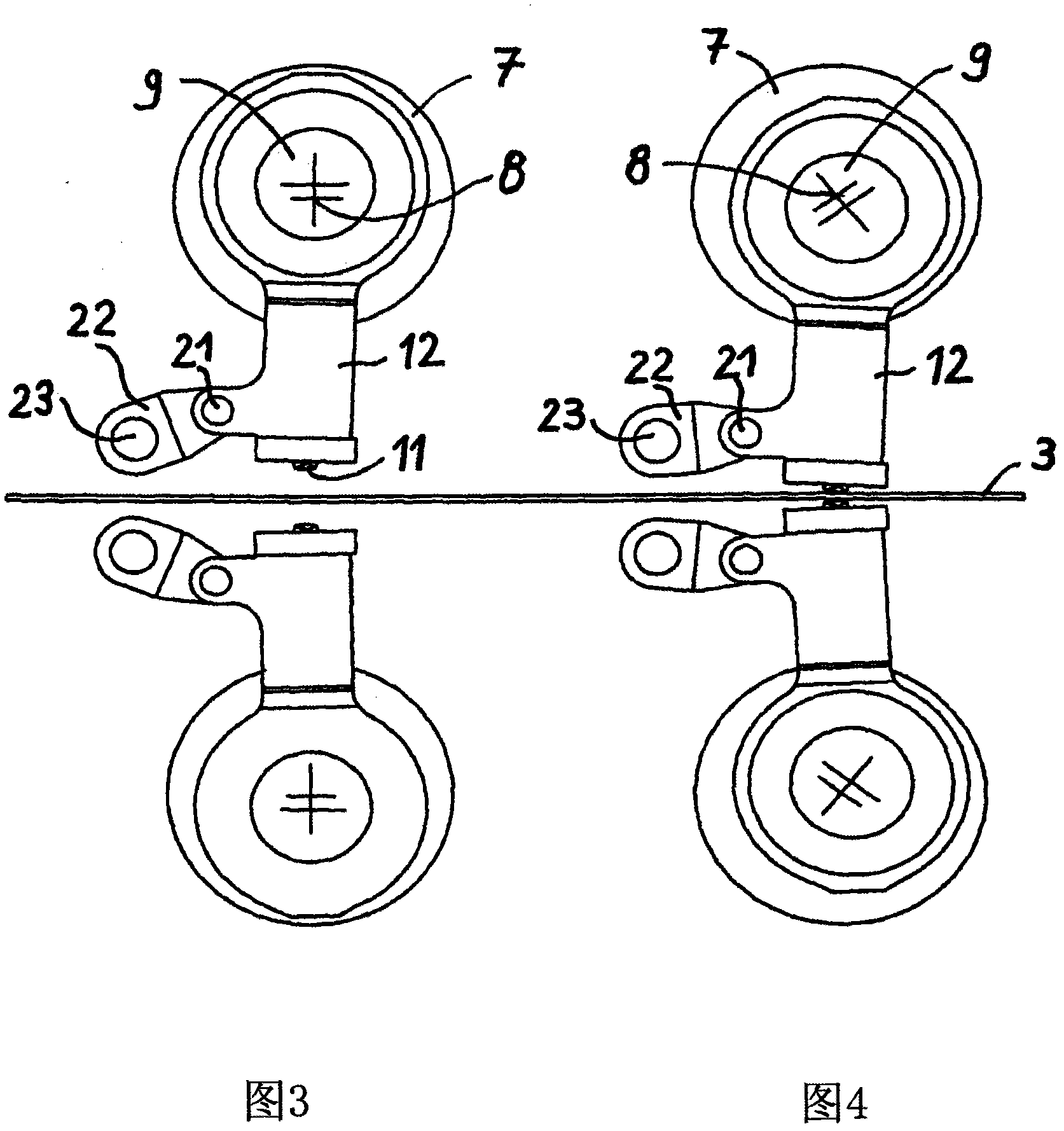

[0025] In the following description of the figures, corresponding parts are always given the same references in the different exemplary embodiments.

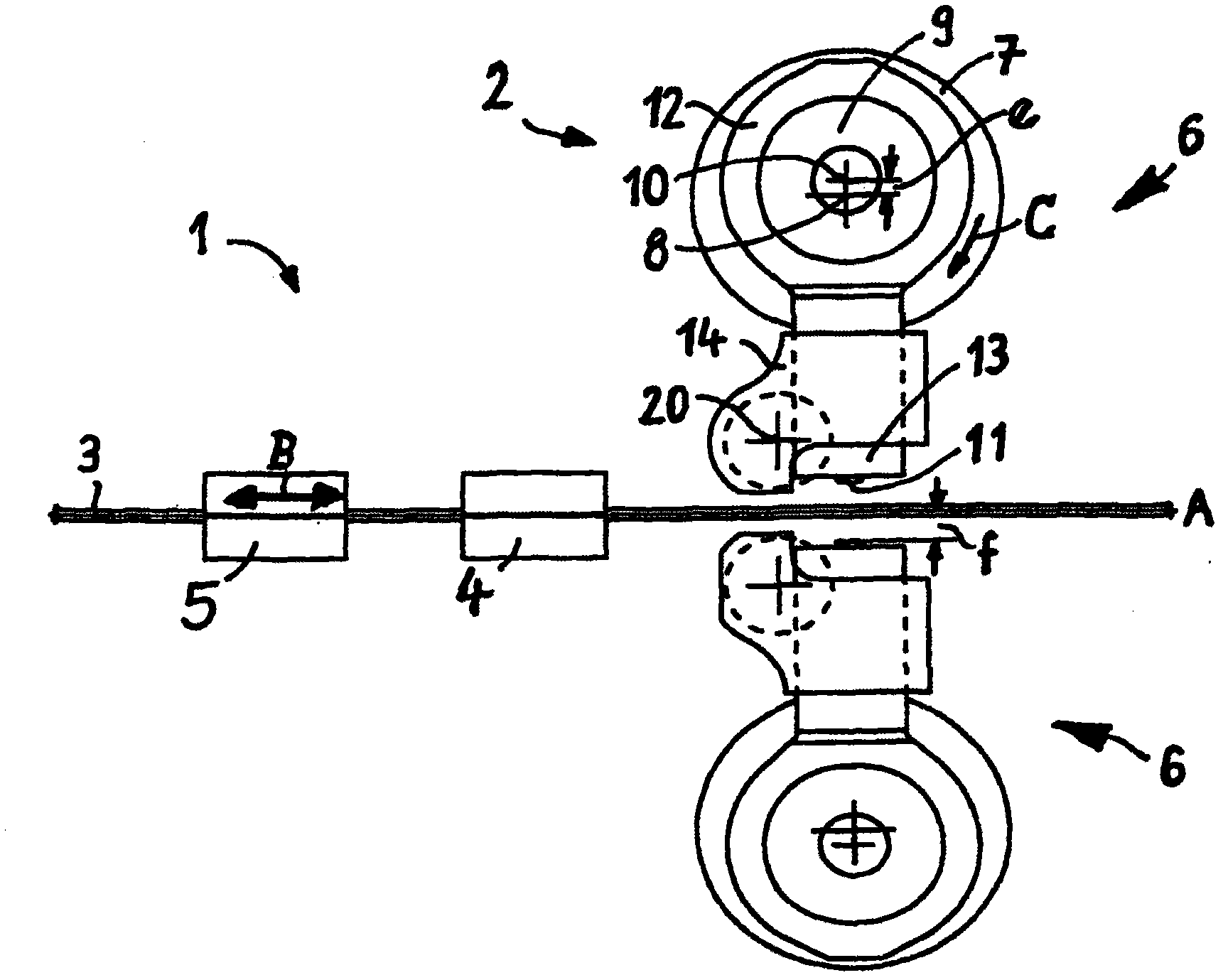

[0026] figure 1 The shown distributing device for cutting nail blanks comprises a feeder 1 and a cutting member 2 for cutting off, simultaneously forming and sharpening workpieces 3 (in top view).

[0027] Such as figure 1 , the feed member 1 is only schematically represented with a fixed feed clamp 4 and a movable feed clamp equipped with clamping jaws or other parts (not shown) that hold the workpiece 3 (wire) in place. 5 clamp feed.

[0028] During operation, the mobile feed clamp 4 grips the wire 3 in a left-hand end position and pushes it to the right during movement in the direction B of the mobile feed clamp 5 parallel to the longitudinal axis A of the wire. In the right-hand end position, the fixed feed clamp 4 clamps the wire 3, whereupon the mobile feed clamp 5 can be opened and returned to its left-hand starting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com