Process of extracting isothiocyanates

A technology of isothiocyanate and glucosinolate, applied in biochemical equipment and methods, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve the problems of accelerated reaction, low efficiency and time-consuming large-scale process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] White mustard essential oil is produced by adding water to ground white mustard seeds and then extracting the essential oil with supercritical carbon dioxide according to known methods described in the art. After extraction, residual moisture is immediately removed from the essential oil by centrifugation or drying under vacuum. The resulting essential oil of white mustard contained about 25% by weight of 4-hydroxybenzyl isothiocyanate. The essential oils were suspended in aqueous phosphate buffer (pH about 3.6) at room temperature (approx. isothiocyanate content. After 24 hours, the percent reduction in the 4-hydroxybenzyl isothiocyanate content was about 72%. Thus, 4-hydroxybenzyl isothiocyanate is a moisture sensitive isothiocyanate compound.

Embodiment 2

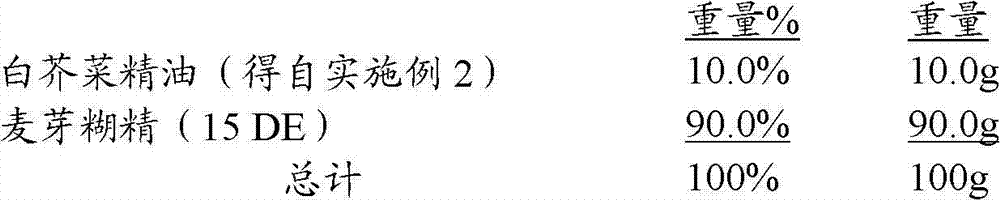

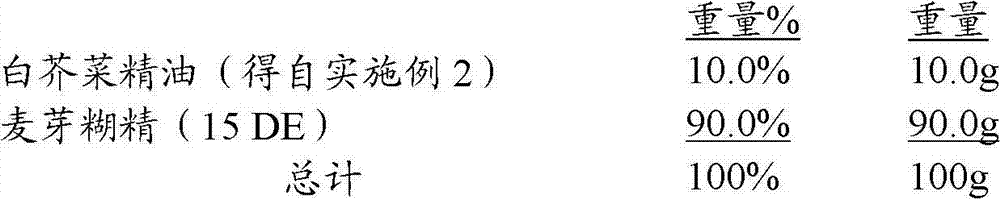

[0094] White mustard essential oil was prepared as follows: 800 kg of white mustard seeds were first cold pressed using a Rosedowns Mini 200 screw press unit. The resulting pressed cake exits the press at about 75-78°C and is immediately cooled to room temperature by hammer milling. The oil content of the pressed cake was 17%. About 340 kg of hammer milled white mustard press cake was added to the belt blender and 78 g of ascorbic acid was added to it while blending to ensure uniform mixing. Add about 102 kg of tap water in small proportions at room temperature to ensure uniform moistening of the pressed cake. After mixing for approximately 10-15 minutes, the wet and myrosinase-activated press cake was transferred to an agitated solvent tank containing 626 kg of ethyl acetate. The activated wet mustard press cake and ethyl acetate slurry were stirred in a closed solvent tank for about 4 hours at room temperature to ensure that 4-hydroxybenzyl isothiocyanate was generated fro...

Embodiment 3

[0097] White mustard essential oil was prepared as follows: 5 kg of white mustard seeds were first cold pressed using a KK8 type single-screw press (KERNKRAFT, Moosbauer and Rieglsperger GbR. Germany) to obtain a white mustard press cake with 6.8% fixed oil and a temperature of about 60 °C . The pressed cake was hammer milled to provide a homogeneous powder and 151.5 g of powder was weighed out on the weighing pan. In a closed mixing vessel equipped with an overhead stirrer, combine 45.5 g of tap water with 305 mL of ethyl acetate and 0.036 g of added ascorbic acid while stirring. Immediately after adding the ascorbic acid, add the partially defatted mustard powder to the mixing vessel and mix at high speed to ensure a uniform dispersion. When a homogeneous slurry had formed, the rate was reduced and mixing continued for an additional 4 hours. At this point the slurry was removed from the mixing vessel and centrifuged to separate the ethyl acetate from the partially defatted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com